When businesses look for cost-effective, durable, and versatile materials, extruded plastic profiles in India are often at the top of the list. These profiles are widely used across construction, automotive, electrical, and industrial sectors because they combine strength with design flexibility. For bulk buyers and manufacturers, understanding the benefits and applications of plastic extrusion helps in making smarter purchasing decisions.

Wide Material Options

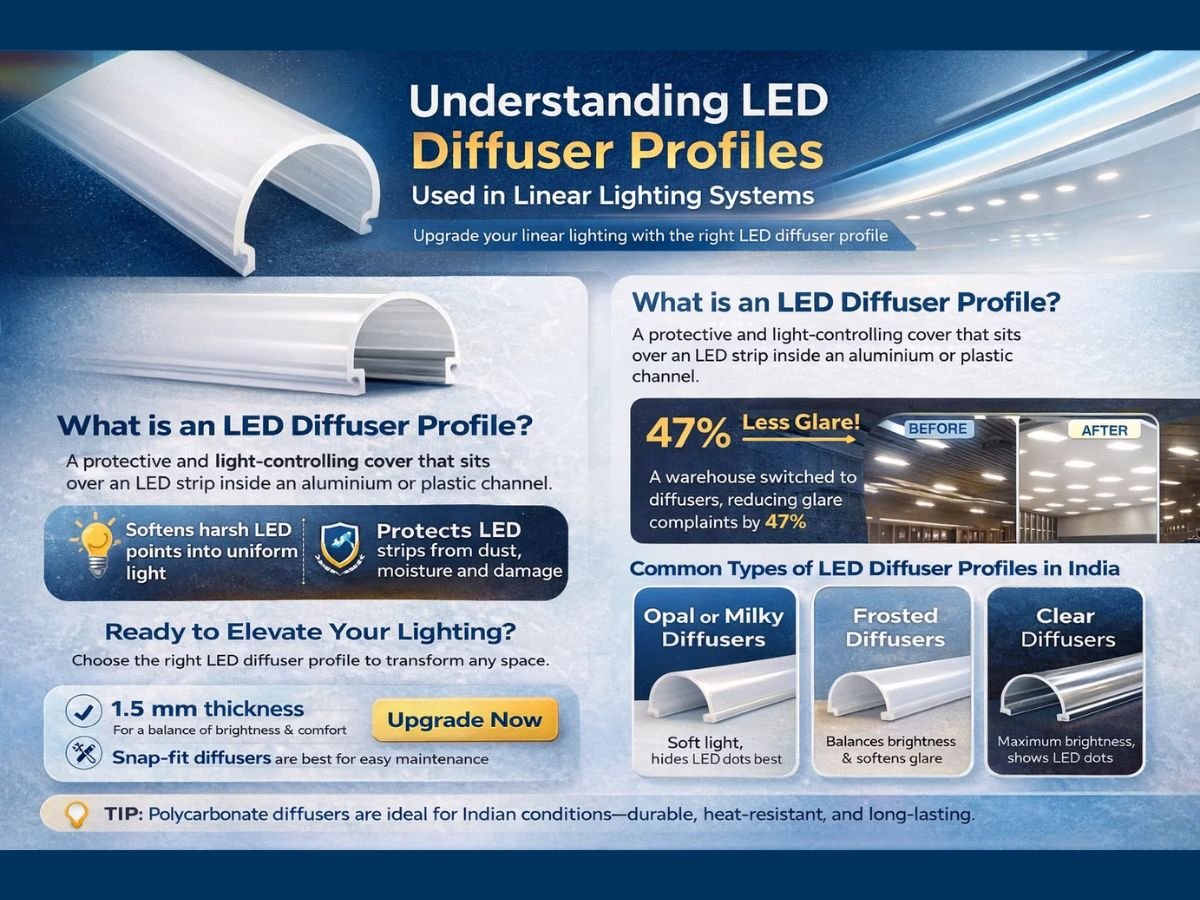

Extruded profiles can be manufactured from PVC, ABS, polycarbonate, polyethylene, and more. Each material has its own strength, flexibility, and resistance properties, making it possible to match the profile with the intended use.

- PVC is known for durability and cost-efficiency.

- Polycarbonate offers high impact resistance.

- ABS is suitable for industrial applications requiring toughness.

Cost Efficiency in Bulk Supply

For large-scale projects, buying extruded profiles in bulk significantly lowers per-unit cost. Manufacturers in India specialise in bulk extrusion supply, giving businesses predictable pricing and consistent quality over time. This makes them suitable for both domestic infrastructure projects and international trade.

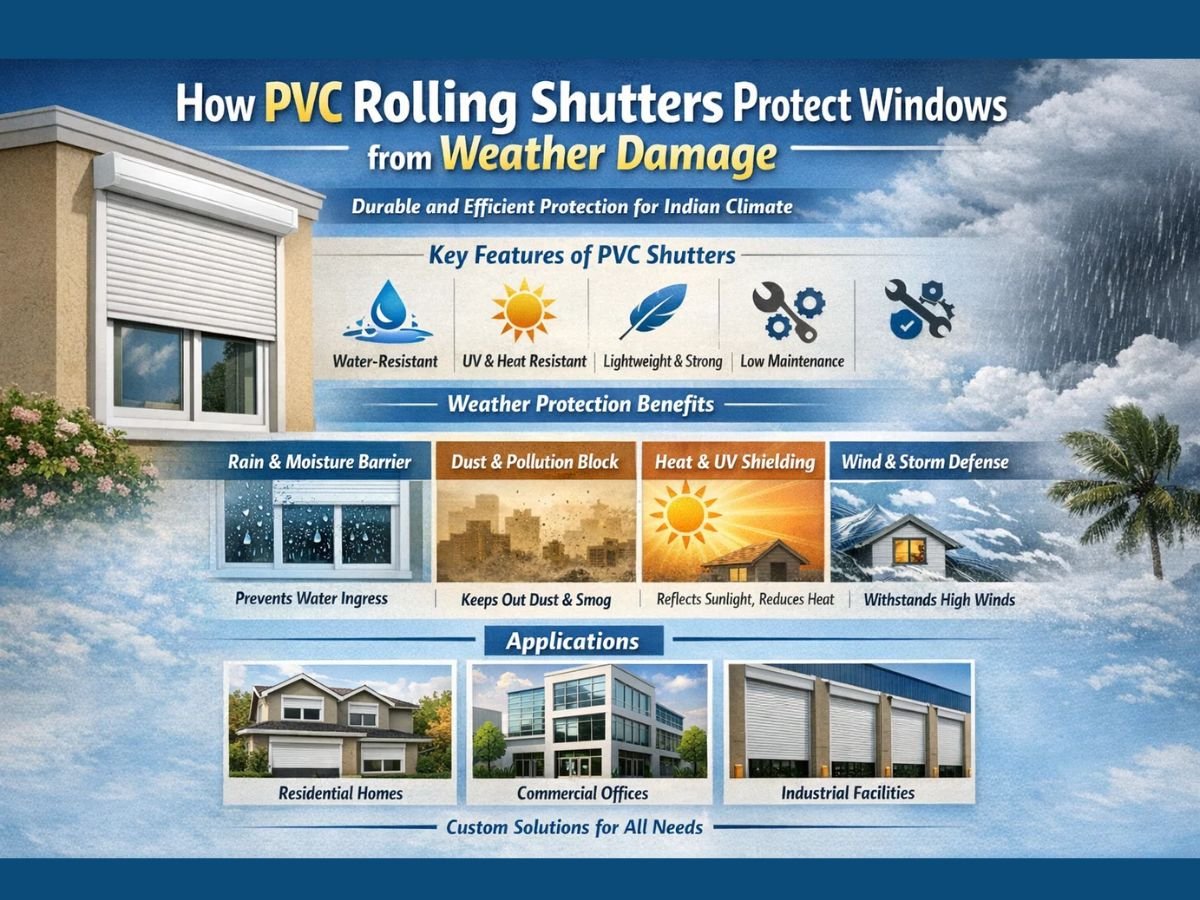

Durability and Weather Resistance

A major advantage of extruded plastic is resistance to weather conditions such as heat, moisture, and UV exposure. Profiles maintain their shape and performance in outdoor applications like cladding, window frames, or protective barriers. This lowers maintenance costs and replacement frequency.

Customisation for Design Flexibility

Extrusion allows manufacturers to create profiles in any shape, size, or colour. This flexibility makes them ideal for unique designs in construction, retail fixtures, or industrial equipment. Custom tooling ensures consistent production even when profiles are highly specialised.

Lightweight Yet Strong

Extruded plastic profiles strike a balance between low weight and high strength. This is particularly useful in transport, packaging, and infrastructure, where reducing material weight lowers logistics costs without compromising safety.

For related insights, you can see how profiles play a role in scalable production here:

👉 The Role of Plastic Profiles in Supporting Scalable Production Needs

Electrical and Thermal Insulation

Certain plastics, such as PVC and polyethylene, provide strong electrical and thermal insulation. This makes extruded profiles a reliable choice in cable ducts, electrical panels, and industrial machinery covers, ensuring safety along with performance.

Sustainability and Recycling Potential

Modern extrusion focuses on sustainability. Many profiles can be manufactured using recyclable plastics, reducing waste and supporting eco-friendly initiatives. With stricter environmental regulations, buyers benefit from using profiles that meet sustainability standards.

Precision Manufacturing for Consistency

One of the biggest advantages of extrusion is precision. Whether producing thousands of metres of window profiles or intricate industrial components, extrusion ensures every piece matches the design exactly. Consistency is especially important for large projects where uniformity is key.

Low Maintenance Requirements

Extruded profiles are easy to clean, resistant to corrosion, and require little upkeep. This makes them a cost-effective option over the long term, especially in sectors like construction and transport, where ongoing maintenance can be expensive.

Growing Demand in India and Abroad

The use of extruded plastic profiles in India is increasing across industries such as housing, energy, and automotive. With infrastructure growth and global exports, Indian manufacturers are well-positioned to meet both local and international demand. Buyers benefit from a competitive market offering reliable supply and diverse options.

FAQs on Extruded Plastic Profiles

Q1. What are extruded plastic profiles?

Extruded plastic profiles are shapes made by forcing melted plastic through a die. They are widely used in construction, automotive, packaging, and industrial applications due to their strength, versatility, and cost-effectiveness.

Q2. Where are plastic profiles commonly used?

Plastic profiles are used in window frames, electrical cable ducts, cladding, furniture, automotive trims, and packaging. Their adaptability makes them suitable for many sectors.

Q3. Why are extruded profiles popular in India?

India has a strong manufacturing base for extrusion with cost advantages, bulk supply capabilities, and access to raw materials. This makes Indian suppliers attractive to both domestic and global buyers.

Q4. Are extruded profiles sustainable?

Yes. Many profiles are made with recyclable plastics and are long-lasting, which reduces replacement needs. They support eco-friendly initiatives in modern infrastructure projects.

Q5. How do I select the right plastic profile for my project?

Choosing the right profile depends on the material, required strength, exposure to weather, and intended use. Consulting a manufacturer helps align material choice with application needs.

Conclusion

Extruded plastic profiles provide a combination of cost savings, durability, and versatility that meets the needs of modern infrastructure and industrial projects. For bulk buyers and manufacturers, understanding these ten insights makes procurement decisions easier and more reliable. With their wide applications and increasing demand, these profiles will continue to play a critical role in global and Indian markets.