PVC (Polyvinyl Chloride) extrusion profiles are essential components in various industries, from construction and automotive to telecommunications and consumer goods. These profiles are produced through the extrusion process, where heated PVC material is forced through a die to create shapes of various sizes and complexities. The versatility, durability, and cost-effectiveness of PVC make it a popular choice for producing a wide range of products, including windows, doors, pipes, and electrical conduits.

However, the importance of quality in plastic PVC extrusion profiles cannot be overstated. In this blog, we’ll explore why quality matters in PVC extrusion, the factors influencing it, and the benefits of choosing high-quality profiles for your projects.

1. Durability and Longevity of PVC Extrusion Profiles

One of the primary reasons quality is crucial in PVC extrusion profiles is the impact it has on the durability and longevity of the final product. PVC is inherently durable and resistant to weathering, chemicals, and UV radiation. However, the extrusion process must be carefully controlled to ensure the right balance of material properties, which will determine how well the final product performs in its intended application.

High-quality PVC profiles are less prone to warping, cracking, or discoloration over time. Low-quality extrusion profiles, on the other hand, might suffer from these issues more quickly, leading to shorter lifespans and potential performance failures. For example, window frames, pipes, and exterior cladding made from inferior PVC materials can degrade faster when exposed to the elements, increasing the need for repairs or replacements.

2. Consistency in Dimensions and Shape

Precision in the dimensions and shape of PVC extrusion profiles is essential for their proper function and integration into final products. In many cases, profiles are designed to fit into specific spaces or interlock with other components. If the dimensions of the profile are off, it can lead to poor fitment, gaps, or even failure of the assembly.

Quality control in the extrusion process ensures that each profile meets strict dimensional tolerances, which is critical for industries that require high levels of precision, such as construction or automotive manufacturing. A consistent, high-quality profile ensures that components fit together correctly, resulting in better functionality, less wastage, and improved production efficiency.

3. Aesthetic Appeal and Surface Finish

The appearance of PVC extrusion profiles is important, particularly in applications like building construction, where the aesthetics of window frames, door sills, and decorative trims matter. A smooth, uniform surface finish is a sign of quality, as it reflects the care taken during the extrusion process. Low-quality profiles may have surface defects, such as rough spots, discoloration, or visible imperfections, which can detract from the visual appeal of the product.

In industries like architecture, design, and interior finishing, the aesthetic quality of PVC profiles plays a significant role in the overall perception of a building or product. Using high-quality PVC extrusion profiles ensures that the finished product looks polished and professional.

4. Enhanced Performance in Specific Applications

PVC extrusion profiles are often used in demanding applications where performance is key. For example, in the plumbing industry, pipes and fittings made from PVC must be resistant to pressure, temperature fluctuations, and corrosion. In the automotive sector, profiles are used in components like seals, trims, and interior elements, where they need to withstand various environmental conditions, such as heat, humidity, and physical stress.

The quality of the PVC material used and the precision of the extrusion process directly affect how well the profiles perform in these specific applications. High-quality PVC extrusion profiles exhibit superior mechanical properties, such as tensile strength, impact resistance, and flexibility, which are essential for maintaining performance and safety standards.

5. Cost-Efficiency and Waste Reduction

While it might seem tempting to opt for cheaper, lower-quality PVC profiles to cut costs, this can lead to more significant expenses in the long run. Low-quality profiles are more likely to suffer from defects, misalignments, and failures during installation or use, leading to additional costs in terms of replacements, repairs, or downtime.

On the other hand, investing in high-quality PVC extrusion profiles reduces the likelihood of defects, ensuring a smoother production and installation process. This translates into reduced waste, less rework, and lower overall production costs. Quality PVC profiles also result in fewer product returns, improving customer satisfaction and reducing the need for expensive warranty claims.

6. Environmental Impact and Sustainability

In today’s world, sustainability is becoming an increasingly important factor for businesses and consumers alike. High-quality PVC extrusion profiles can be more environmentally friendly due to better material usage, energy efficiency in manufacturing, and longer product lifespans.

When manufacturers use high-quality PVC, they tend to produce more precise profiles, leading to less material waste during production. Furthermore, higher-quality profiles are less likely to break down or require replacement, reducing the need for disposal and minimizing waste over time. Some PVC profiles are also recyclable, contributing to sustainability goals. By choosing high-quality products, businesses can align themselves with eco-friendly practices while benefiting from a product that will last longer and perform better.

7. Safety Standards and Compliance

Certain industries, such as the construction and electrical sectors, require PVC profiles to meet stringent safety standards and regulatory requirements. For instance, PVC profiles used in electrical conduits must be resistant to fire, while those used in construction must comply with building codes for load-bearing and weather resistance.

High-quality PVC extrusion profiles are more likely to meet these safety standards because they are produced with precise control over material properties and dimensions. They are also subjected to thorough testing and quality assurance processes to ensure they meet or exceed the necessary compliance regulations.

Low-quality profiles, by contrast, may fail to meet these critical safety standards, putting end-users at risk and potentially leading to legal or financial repercussions for manufacturers.

Final Thoughts

Quality is a crucial factor in the production and performance of PVC extrusion profiles. Whether for aesthetic purposes, durability, performance, or safety, the importance of high-quality profiles cannot be overstated. Choosing high-quality PVC profiles ensures longevity, reliability, and overall satisfaction, while also providing cost-efficiency and sustainability benefits.

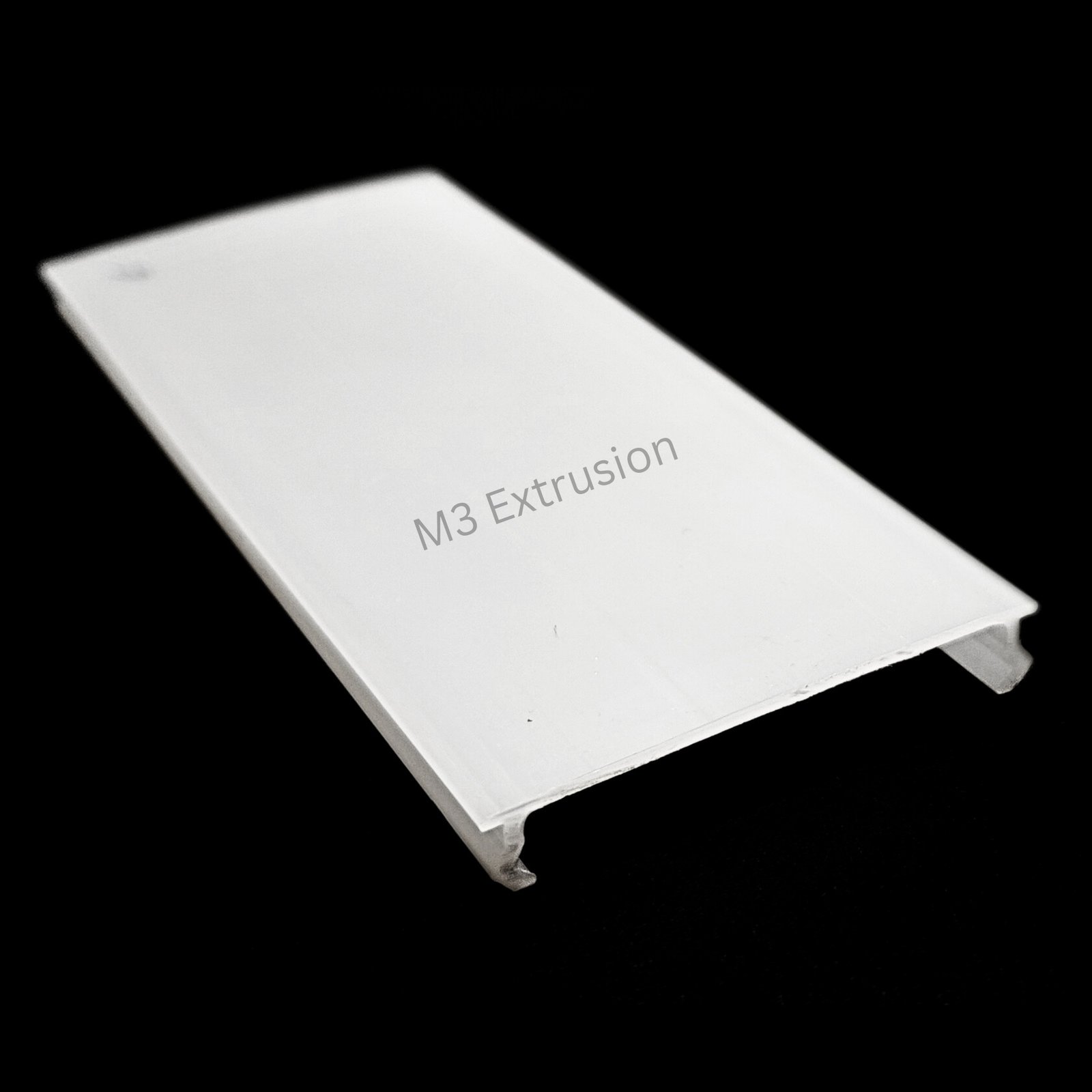

At M3 Extrusion, we understand the importance of quality in PVC extrusion profiles and are committed to delivering products that meet the highest standards. Our expertise in the extrusion process, combined with rigorous quality control, ensures that our customers receive profiles that not only meet their technical requirements but also exceed their expectations for performance and appearance. Trust M3 Extrusion for all your PVC extrusion needs, and experience the difference that quality makes.