In the world of modern refrigeration, efficiency, reliability, and durability are critical factors that businesses and industries must prioritize to ensure their systems function optimally. Cooling systems are essential across various sectors, from food preservation to industrial and commercial refrigeration. Over the years, advancements in materials and design have played a significant role in improving these systems. One such advancement is the use of PVC (Polyvinyl Chloride) refrigeration profiles.

What are PVC Refrigeration Profiles?

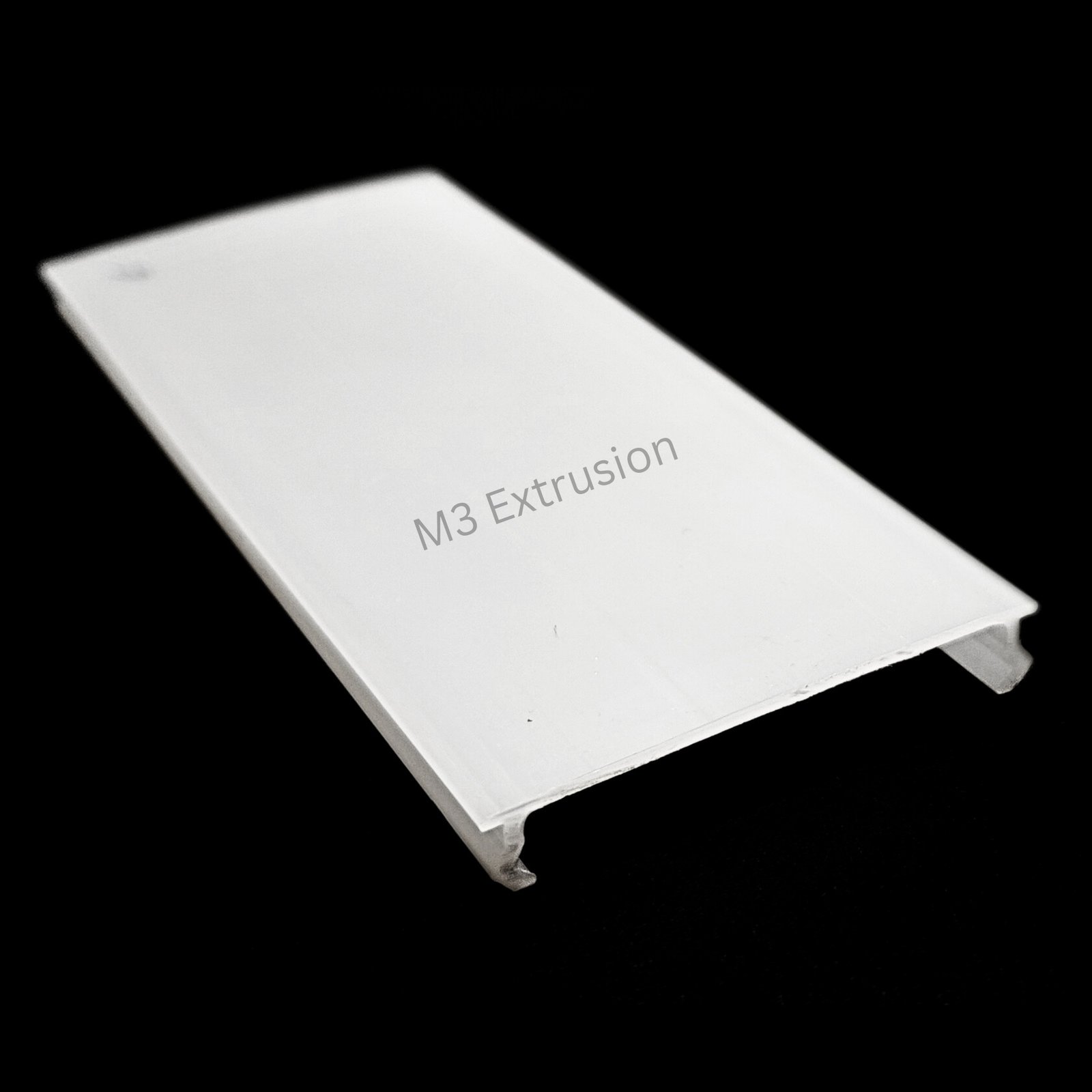

PVC refrigeration profiles are specialized plastic components made from Polyvinyl Chloride (PVC) that are used in the construction, sealing, and insulation of refrigeration systems. These profiles are extruded into various shapes, sizes, and forms to meet the specific needs of refrigeration applications. PVC itself is a durable, versatile plastic known for its resistance to corrosion, moisture, and temperature extremes, making it an ideal material for use in cooling systems.

PVC profiles are designed to serve multiple functions within refrigeration units, including structural support, insulation, sealing, and protection. The flexibility of PVC allows manufacturers to create custom profiles tailored to meet the unique requirements of different refrigeration systems. Whether in commercial refrigerators, industrial freezers, or cold storage units, PVC refrigeration profiles are integral components that contribute to overall system performance.

What Are PVC Refrigeration Profiles Used For?

PVC refrigeration profiles have a wide range of applications within refrigeration systems, and they serve critical roles in enhancing the performance and longevity of these systems. Below are some of the key uses of PVC refrigeration profiles:

1. Insulation Seals and Gaskets

One of the primary uses of PVC refrigeration profiles is for insulation. These profiles are often used as seals and gaskets around refrigeration doors and compartments to maintain temperature control. By providing a tight seal, PVC profiles help prevent heat from entering the system and cold air from escaping, which is essential for energy efficiency.

2. Structural Components

PVC profiles are used as structural components in refrigeration systems, providing stability and support to various parts of the system. These components help to maintain the integrity of the unit while withstanding the stress and strain that refrigeration systems may face, especially in high-performance or industrial settings.

3. Door and Window Frames

PVC refrigeration profiles are commonly used for the framing of doors and windows in refrigeration units. Their ability to maintain integrity in cold temperatures, combined with their insulation properties, makes them perfect for framing doors in commercial refrigerators, freezers, and cold storage areas.

4. Trims and Decorative Finishes

While functionality is the primary concern in refrigeration systems, aesthetics are also important in commercial settings. PVC profiles can be used as trims or decorative finishes around refrigeration units, offering a polished, professional look while also maintaining the system’s integrity.

5. Vibration Dampening

In certain refrigeration applications, PVC profiles can be used to reduce vibrations. These profiles can be placed in key areas of the system to minimize noise and mechanical stress, contributing to the overall efficiency and longevity of the refrigeration unit.

6. Protective Covers and Casings

PVC profiles are also used to protect the delicate components of refrigeration systems from external damage. Protective casings made from PVC can shield the internal parts of refrigeration units, ensuring they remain intact and functioning optimally even under harsh conditions.

7. Custom Solutions for Specialized Applications

Given that refrigeration systems vary widely across industries (from food storage to pharmaceuticals), PVC profiles are often customized to meet the specific needs of different applications. Whether it’s a custom seal, trim, or support profile, PVC offers a flexible, cost-effective solution for specialized refrigeration needs.

The Importance of PVC Refrigeration Profiles in Modern Cooling Systems

1. Improved Insulation for Energy Efficiency

One of the most significant factors contributing to the increased use of PVC refrigeration profiles in modern cooling systems is their ability to enhance insulation. Refrigeration relies heavily on maintaining consistent internal temperatures, and any fluctuation can lead to energy loss and inefficiency. PVC profiles, with their excellent thermal insulating properties, play a key role in minimizing energy consumption.

PVC profiles help maintain the integrity of the insulation around refrigeration equipment by reducing heat transfer. This is especially important for systems such as cold storage, freezers, and industrial refrigeration units, where energy efficiency is critical to reducing operational costs. With PVC profiles, energy loss is significantly minimized, leading to lower energy bills and a more sustainable system.

2. Durability in Harsh Environments

PVC is a durable and resilient material that can withstand extreme temperatures, moisture, and even chemical exposure, making it ideal for refrigeration applications. Refrigeration systems are often subject to harsh operating conditions, such as low temperatures and exposure to chemicals used in cleaning or maintenance. PVC profiles offer long-term resistance to such conditions, ensuring the system operates reliably over time.

The durability of PVC refrigeration profiles also translates into extended lifespans for refrigeration systems. Unlike materials that may degrade or corrode over time, PVC maintains its structural integrity even in extreme conditions. This reduces the need for frequent replacements or repairs, providing businesses with cost savings and less downtime.

3. Moisture Resistance and Corrosion Prevention

Refrigeration systems are regularly exposed to moisture, which can lead to corrosion and deterioration of components. This is particularly true for metal profiles or seals used in older refrigeration systems, which can rust and weaken over time. PVC, however, is inherently resistant to moisture and does not corrode, rust, or degrade when exposed to water or humidity.

This property is especially critical in environments such as cold storage rooms or industrial freezers, where moisture levels can be high. PVC refrigeration profiles maintain their shape and function over time, even in wet conditions, ensuring that the cooling system stays sealed and operates effectively.

4. Customizability and Versatility

Modern refrigeration systems come in a wide range of shapes, sizes, and designs to meet the needs of different industries. From small commercial refrigerators to large-scale industrial chillers, each system requires specific components that fit precisely. PVC profiles are highly customizable, which allows manufacturers to create profiles tailored to the exact dimensions and requirements of each refrigeration system.

The versatility of PVC profiles means they can be used in various parts of a refrigeration system. They can be molded into seals, trims, gaskets, and even structural supports, making them a flexible choice for different applications. Additionally, PVC can be easily molded into complex shapes, which allows manufacturers to meet the exact specifications required for diverse cooling needs.

5. Cost-Effective Solution

In comparison to other materials, PVC is relatively affordable, making it an economical choice for refrigeration manufacturers and businesses looking to optimize their cooling systems. PVC profiles offer all the advantages of durability, insulation, and resistance to corrosion at a fraction of the cost of metal or other alternatives. This cost-effectiveness is particularly attractive for businesses that need to maintain strict budget control while ensuring high-quality performance from their refrigeration systems.

Moreover, the longevity of PVC profiles reduces the need for frequent maintenance and replacement, further adding to their cost-effectiveness. When considering both initial costs and long-term savings, PVC refrigeration profiles are an excellent investment for modern cooling systems.

6. Easy Installation and Maintenance

PVC refrigeration profiles are lightweight and easy to handle, making them straightforward to install. Installation efficiency is critical in industries where downtime must be minimized, such as supermarkets, restaurants, and warehouses. The ease of installation associated with PVC profiles reduces the amount of labor and time required for installation, allowing businesses to keep their cooling systems running smoothly with minimal disruption.

Additionally, maintenance of PVC profiles is simple, as the material is easy to clean and does not require special treatments to retain its properties. PVC refrigeration profiles also do not need complex repairs, making maintenance more manageable and cost-effective.

7. Environmental Impact and Sustainability

With growing concern over environmental impact, many industries are seeking sustainable solutions. PVC profiles can be made from recycled materials, and the production of PVC itself has become more eco-friendly over the years. Moreover, the energy efficiency provided by PVC refrigeration profiles leads to a reduction in overall energy consumption, further decreasing the environmental footprint of refrigeration systems.

Furthermore, because PVC profiles are durable and long-lasting, they help reduce waste by extending the lifespan of refrigeration components and systems. This means less waste ends up in landfills, contributing to a more sustainable cooling solution.

8. Compliance with Industry Standards

PVC refrigeration profiles are manufactured to meet the stringent regulations and standards in the refrigeration and food safety industries. These profiles help ensure that refrigeration systems comply with health and safety regulations, which is especially important in food storage, pharmaceutical storage, and other sectors where temperature control is critical.

The use of PVC in refrigeration systems allows businesses to meet the necessary safety standards while ensuring that their systems are functioning at peak efficiency. PVC’s ability to resist contamination, maintain hygiene, and withstand temperature fluctuations makes it a key material in compliance with industry standards.

9. Aesthetics and Design Flexibility

While functionality is the primary concern for refrigeration systems, the aesthetic aspect is also important, especially in commercial and retail settings. PVC profiles are available in a variety of colors and finishes, allowing businesses to choose the best design for their space. This level of customization ensures that refrigeration systems can integrate seamlessly with the overall design of a facility, whether it’s a supermarket, restaurant, or office building.

Additionally, PVC can be designed to fit various aesthetic preferences, whether a sleek, modern look or a more traditional appearance. The aesthetic flexibility offered by PVC profiles enhances the visual appeal of refrigeration systems without compromising on performance.

10. The Future of PVC Refrigeration Profiles

As refrigeration technology continues to evolve, the use of PVC refrigeration profiles is expected to grow. The increasing demand for energy-efficient, durable, and environmentally friendly cooling systems will drive further innovation in PVC materials and designs. Future advancements may focus on improving the recyclability of PVC, enhancing its insulation properties, and making it even more resistant to environmental stressors.

In addition, with growing concerns about sustainability and energy conservation, the role of PVC in reducing the carbon footprint of cooling systems will become increasingly important. As industries continue to adopt greener practices, PVC refrigeration profiles are well-positioned to play a significant role in shaping the future of refrigeration technology.

Conclusion

PVC refrigeration profiles are an essential component in modern cooling systems, offering a wide range of benefits that enhance the efficiency, durability, and sustainability of refrigeration technologies. Their excellent insulation properties, moisture resistance, customization options, and cost-effectiveness make them an ideal choice for a variety of refrigeration applications. As the demand for energy-efficient and eco-friendly cooling solutions continues to grow, M3 Extrusion remains dedicated to providing high-quality, custom PVC profiles that meet the evolving needs of the industry. With continued advancements in material technology, these profiles will continue to help modern cooling systems meet the highest standards of performance and environmental responsibility. Whether for commercial, industrial, or food preservation purposes, PVC refrigeration profiles from M3 Extrusion will remain a trusted solution for years to come.