In today’s challenging business world, manufacturers continue to find ways to refine their process, save costs, and be efficient in every sense of the word. Custom flexible PVC extrusion has become an easy-to-miss solution to a great many challenges because it has a variety of applications within the different sectors of the industries, including being cost-effective against its traditional materials counterparts and being flexible, durable, and customizable. In this article, we’ll explore how custom flexible PVC extrusion can help businesses save money and streamline their production processes.

Understanding Flexible PVC Extrusion

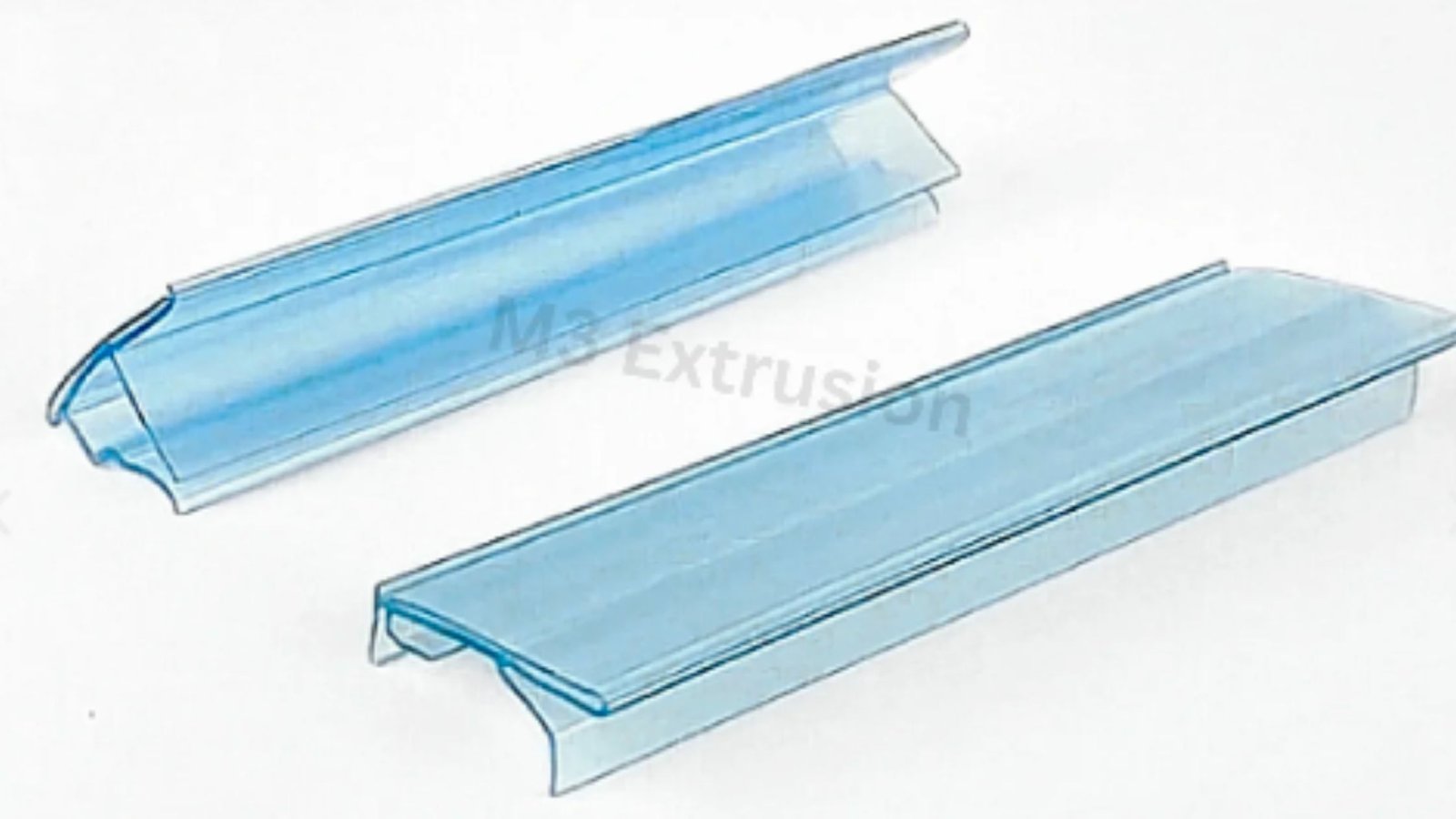

Extruded flexible PVC or Polyvinyl Chloride is an application in which PVC material, after having heated up enough to soften the material, is pressed through a die, making the continuous profile. A continuous profile of such PVC may then be cut to preferred length or fashioned into whatever desired shape. “Flexible” means it retains shape in normal circumstances, yet under the condition of pressure will bend and twist with its stretch capability without breaking off or cracking.

Custom flexible PVC extrusion is a process whereby these profiles are tailored to fit the specific needs of a business or industry. A manufacturer can change the makeup of the material, the color, thicknessThe Main Advantages of Custom Flexible PVC Extrusion, and flexibility to make profiles fit for specific applications such as seals, gaskets, tubing, and protective coverings. This degree of customization has many benefits that can result in significant cost savings for businesses.

The Main Advantages of Custom Flexible PVC Extrusion

1. Cost-Effective Material Selection

Probably the first cost-cutting method custom flexible PVC extrusion can save money in the inherent material itself. PVC is regarded as one of the cheaper plastics in contrast to other materials such as metals, rubber, or polyurethane. It is relatively abundant, and manufacturing requires less energy than most alternatives. From a business perspective, using PVC in production saves on raw material costs by a large margin.

Custom flexible PVC extrusion enables companies to make the best use of the material by tailoring it exactly to the specifications needed, so no material goes to waste and production processes are kept efficient.

2. Customization for Better Fit and Functionality

The flexibility of PVC extrusion profiles allows the production of custom products that precisely match manufacturer requirements, as opposed to standard, off-the-counter applications. It thus avoids additional materials and modifications with lots of time wastage. For example, custom flexible PVC profiles designed specifically for construction or the Building industries can easily be shaped into pre-existing structures for construction, reducing adjustments, thereby saving installation time.

Having the extrusion profiles created to order reduces the chance that manufacturers will use unproductive material for a certain task, thereby removing or reducing the likelihood of losing time and resources related to poorly fitting parts, decreasing costs.

3. Decrease waste and maximize the efficiency of materials

This helps in material efficiency. Cut sheets or blocks of traditional manufacture methods often result in considerable waste. Custom flexible PVC extrusion allows a profile to be developed accurately to meet the needs of the application. This can actually reduce scrap and unnecessary utilization of material, thereby giving a lower material cost.

By ordering only the amount of requirement and ensuring that every piece of material is used to the optimal capacity, businesses can go easier with their production processes and avoid this surplus stock. This will not only save on raw material costs but also improve supply chain management, thereby resulting in many subsequent costs.

4. Increased Durability and Longer Lifespan

Custom flexible PVC profiles are durable. PVC does not react to water, chemicals, UV rays, and heat. This implies that this type of profile is very effective for any outdoor or industrial application whereby the durability of materials becomes a significant factor. Utilizing flexible PVC extrusion, producers can give a product with higher durability so that replacing and repairing these products would rarely be in demand.

For construction, automotive, and packaging industries, for which long-term durability is a major concern, the long life of flexible PVC profiles can translate into savings. The lesser the replacements, the lesser would be the expenses pertaining to maintenance, repair, or part replacements, keeping businesses’ costs under control in the long run.

5. Reduced Labor Costs

The other way is through savings in labor cost. If the manufacturer can opt for a custom-made flexible PVC extrusion tailored to fit his specific requirements, the installation and assembly processes become much easier and streamlined. The time that would have been spent adjusting or making alterations to assemble the profile can be considerably reduced in a custom-made profile. Thus, saving on labor costs.

In addition, flexible PVC profiles are relatively easy to manipulate and install compared to other alternatives. The flexibility of the material enables faster assembly and incorporation into different products and systems, which lowers labor cost and enhances productivity.

6. Enhanced Product Performance

Another major way custom flexible PVC extrusion saves money is through the improvement in the final product’s performance. While PVC profiles are engineered to perform specific functions, such as sealing, insulation, or shock absorption, without the use of extra parts or materials, several cost savings can also be realized during the design of a product. A manufacturer can reduce the number of components needed.

For instance, in a refrigeration or automotive installation, flexible PVC profiles may be a seal, a gasket, or even an insulating material that fulfills its intended function effectively. In such a case, a company can avoid any need for supplementary parts or the extra processing steps in an assembly and thereby save material and labor costs.

7. Efficient production process

This helps to ease its integration into the process due to custom flexible PVC extrusion. The fewer processes, or the type of material used in manufacture makes less time for producing that commodity, fewer numbers of tools and machines will be used, and reduces a high amount of energy when making it.

Moreover, the process of extrusion itself is very efficient and can be scaled up to meet the demands of high-volume production. So, businesses can achieve economies of scale and reduce the per-unit cost of production. Whether you are producing small batches or large quantities, custom flexible PVC extrusion allows for greater flexibility and cost-effectiveness.

8. Cost-Effective Material Choice Reduced Inventory Costs

Another often overlooked benefit of custom flexible PVC extrusion is that it can help businesses save inventory costs. The profiles could be customized to match the accurate requirements, and businesses need not carry excessive inventory or order materials in large amounts that may not be needed. The ability to order exactly what is needed makes sure that businesses only purchase and store materials they use, thereby reducing the excess stock costs.

Moreover, its long shelf life allows PVC to be stocked for quite some time by companies and still not experience deterioration if such companies happen to deal in industries with slow turns of inventory.

Conclusion

Custom flexible PVC extrusion is an opportunity for wide-ranging cost savings to businesses in a myriad of industries. The benefits range from raw material cost savings and labor expenses to improved product performance and extended lifespans of products. Custom PVC profiles are smart investments for companies looking to optimize their manufacturing processes and improve their bottom lines. The end.

This helps businesses have more efficiency, reduce the waste they create, and ultimately save more. In whatever Refrigeration Industry, Building Industry, Lighting Industry, Hospital Wall Guard, custom flexible PVC extrusion is the flexible yet inexpensive option that will lead you to only one step forward in this competitive market. This innovative practice will not only save cost but also help bring sustainability and long-term success to your business.