Windows are central to any building’s energy efficiency, particularly in transitioning zones of extreme weather conditions. Double glazing has become a popular solution for reducing heat loss as well as improvement in insulation. However, one of the key components that improve their efficiency is based on the spacer profile material: PVC. They prevent very much heat transfer at the edges between glass panes, thus, thermal efficiency is increased to a considerable degree. This article will discuss how PVC warm edge spacer profiles in India contribute to the reduction in heat loss and why they form the basis of construction in modern window systems.

Heat Loss in Double-Glazed Windows

Double-glazed windows consist of two panes of glass separated by a spacer from which a gas of greater insulating quality, usually argon or krypton, is inserted. The arrangement reduces the heat loss to a certain extent compared to windows with single glazing. The bridging action necessarily occurs at the edges at which the glass panes are joined. Traditional alumina or metal ones are especially good conductors of heat. Thus, energy is lost consequently affecting the general insulating performance of the window.

This is where the plastic window spacer profiles enter. The use of non-metallic or PVC-based materials in spacers is meant to reduce heat loss, condensation build-up, and overall thermal efficiency in any window system.

How PVC Spacer Profiles Improve Thermal Efficiency

The primary purpose of PVC warm edge spacer profiles is to impede heat loss by reducing conductive heat transfer. Here is how these improve thermal efficiency:

- Low thermal conductivity. Unlike metal spacers that conduct heat rapidly, strong window spacer parts from PVC provide better insulation.

- Reduced condensation. The heat-resistant spacer profiles maintain an evenly regulated temperature along the edges of the window, thus preventing condensation or moisture from forming.

- Improved insulation performance. With reduced heat trading off the edges of the buildings, less energy is required to keep indoor temperatures comfortable, which in turn equals lower energy consumption.

Energy Savings and Environmental Benefits

The PVC window spacers provide certain energy savings in the global sense of a potential reduction of energy cost. If the spacers reduce heat losses during winter heating and mitigate heat gain during summer cooling, then indoor thermal conditions will stabilize. Such reduced heating and cooling bills become an appealingly attractive reason for both residential and commercial units to invest in.

Moreover, these glazing spacers support the sustenance of the environment with high performance. The lower energy demands ultimately reduce the carbon footprints of a building such that they contribute toward the global drive for energy conservation while helping reduce greenhouse gas emissions.

Enhancing Window Durability with PVC Spacer Profiles

In addition to energy, all show that durable window spacer systems could vastly increase the life span of double-glazed windows. PVC spacers manage thermal shock, resist UV exposure, and moisture, and do not break down quickly at extreme temperatures. Thus, this should assist in keeping the fixed structure of the window and perform better in years.

Due to the elastic arrangement of plastic materials, glass panes in the thermal window can slightly move with the surrounding changes of temperature, reducing seal failure chances and hence preventing moisture from leaking through the insulating layer.

Key Factors to Consider When Choosing Warm Edge Spacers

The choice of the right window frame spacers is essential in ensuring both energy efficiency and durability. To this end, consider the following factors:

- Material Quality: Ensure the spacer is made of high-quality, nonconductive materials for better insulation.

- Compatibility: Choose spacers that fit easily within multiple double-glazed window assemblies.

- Moisture Resistance: Choose insulating profiles of window spacers to prevent condensation and moisture transmission.

- Customization Options: Some manufacturers provide solutions on a custom basis according to design and performance.

Manufacturing Process of PVC Warm Edge Spacer Profiles

The manufacture of PVC warm edge spacer profiles defines a clear and controlled process to obtain optimum quality and performance. The key step involves:

- Material Selection: The selection of material mainly emphasizes high-grade PVC that is rugged in design and differs thermally from other materials.

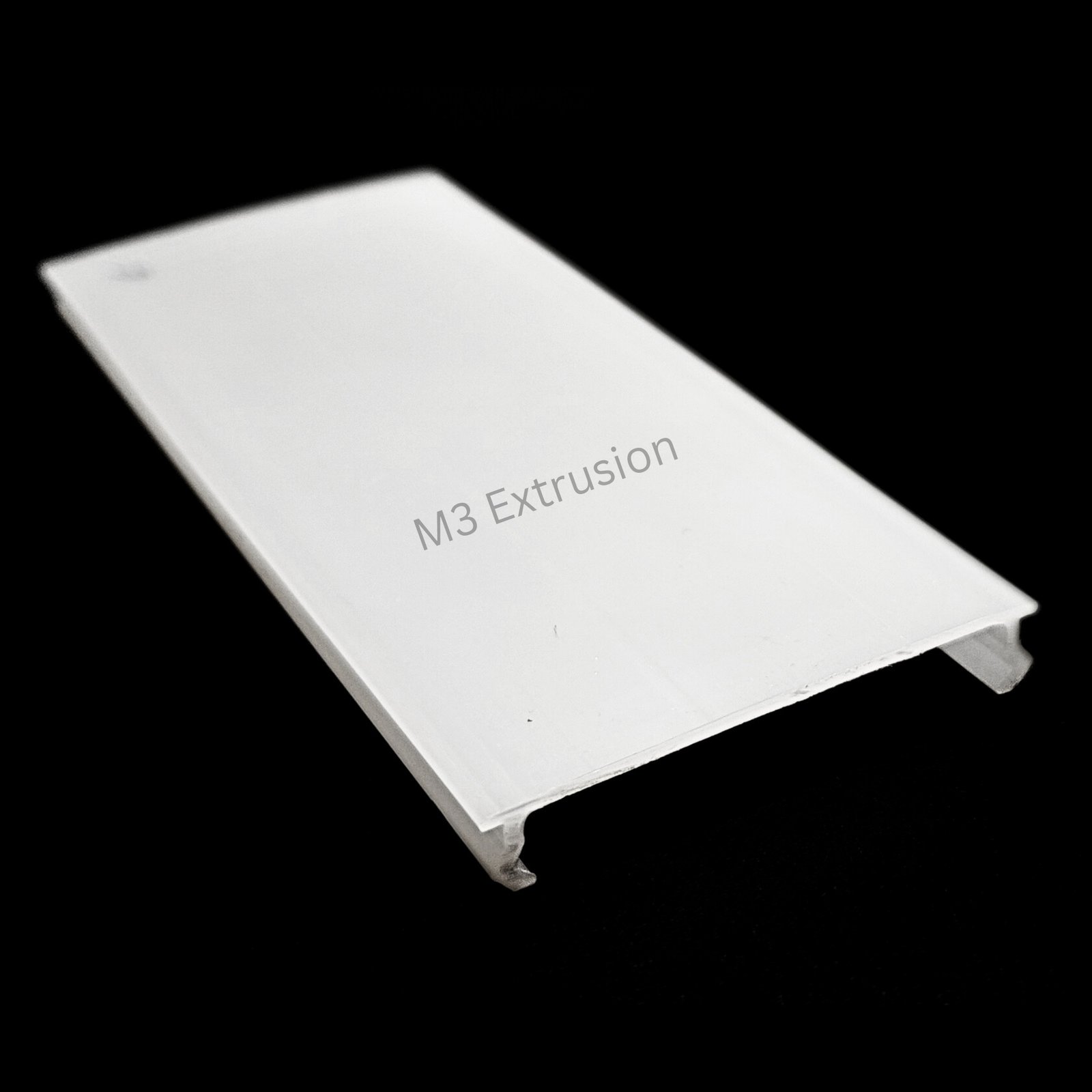

- Extrusion Process: Spacers shaped in rigid dimensions through extrusion of PVC.

- Quality Control: The batch of production is evaluated as necessary by the company’s ISO for insulation and moisture resistance.

- Customization: Spacers can be custom-made as per size, shape, and color.

Such advanced manufacturing guarantees that the benefits derived from the product created will have maximum insulation and durability in the long run.

Applications of PVC Spacers in Modern Window Systems

The dispenser has been put to further use in its many potential applications for window applications:

- Residential Windows: Homeowners seeking energy-efficient solutions can apply these spacers in double-glazed installations.

- Commercial Buildings: Office buildings and commercial spaces improve their insulation performance with high-performance glazing spacers.

- Passive House Designs: Space in energy-efficient construction requires warm-edge plastic spacers to meet thermal performance mandates.

- Industrial Application: Factories and warehouses use these spacers to enhance indoor climate control and save on heating costs.

Conclusion

Working with an established organization like M3 Extrusion ensures the delivery of high-quality PVC spacer profiles in a variety of combinations for each particular client’s needs.

One must state that PVC spacer profiles indeed help in reducing heat loss from windows, most especially double-glazed ones. Indeed, by replacing conventional metal spacers with energy-efficient window spacers, buildings achieve much higher insulation, leading to lower energy costs and enhanced durability, thanks to rigid PVC extrusion technology.

Choosing high-quality PVC warm edge spacer profiles ensures lengthy sustainability and thermal performance benefits for energy-efficient buildings. This would come to gain even more momentum as innovative formulations, like these, will steer the course of creating comfortable buildings with energy-efficient building materials.