When it comes to building construction, managing heat loss and preventing moisture-related problems is crucial for maintaining the integrity of the structure. One highly effective solution that has gained popularity is the use of thermal-break PVC profiles in India. These profiles are essential in creating a barrier that prevents the transfer of heat, while also offering significant protection against moisture and mold growth. In this blog post, we will explore how PVC thermal breaks play a key role in protecting buildings from moisture damage and mold issues, ensuring a healthier and more energy-efficient environment for both residential and commercial properties.

What Are PVC Thermal Breaks?

At their core, thermal break profiles are designed to reduce heat transfer between the interior and exterior of a building. Typically used in windows, doors, and curtain walls, thermal breaks are materials inserted into the frame of a window or door to provide insulation. PVC thermal breaks are specifically made from a type of plastic that offers exceptional insulation properties, making them a top choice for energy efficiency. By preventing heat from escaping in the winter or entering in the summer, they help to maintain a comfortable temperature inside the building.

However, the benefits of PVC thermal breaks go beyond energy efficiency. They also provide protection against moisture, which can lead to a variety of issues such as mold growth, structural degradation, and even health problems. Here’s how these profiles can help in preventing moisture and mold-related issues.

How PVC Thermal Breaks Help Prevent Moisture Accumulation

One of the biggest challenges buildings face is the accumulation of moisture, particularly in areas where temperature differences cause condensation. In simple terms, when warm air inside a building meets cold surfaces such as windows or exterior walls, condensation forms. Over time, this moisture can seep into the building materials, creating the perfect environment for mold to grow.

By using PVC thermal break profiles, you create a physical barrier that prevents this heat transfer. This is important because when heat transfer is minimized, the surface temperature of walls, windows, and doors remains more consistent. As a result, the risk of condensation is significantly reduced, helping to keep the interior of the building dry and free from moisture buildup.

PVC Thermal Breaks: A Barrier Against Mold

Mold is a persistent issue in buildings exposed to excessive moisture. It thrives in areas with high humidity and can cause serious damage to building materials, including wood, drywall, and insulation. Additionally, mold is not just unsightly—it can also pose significant health risks to occupants, including allergies, respiratory issues, and skin irritation.

PVC thermal breaks, by regulating the temperature and reducing condensation, help prevent the formation of mold in the first place. Without moisture on the interior surfaces of the building, mold has little opportunity to grow and spread. This creates a healthier indoor environment for the people who live or work in the building.

The Role of PVC in Thermal Breaks

PVC (Polyvinyl Chloride) is a highly durable and moisture-resistant material, making it ideal for use in thermal insulation components. Unlike metals, which can conduct heat and moisture, PVC acts as an excellent insulator. Additionally, PVC is resistant to corrosion, which is essential in preventing issues caused by humidity and water exposure. The material’s long lifespan and minimal maintenance requirements make it a cost-effective choice for builders and homeowners alike.

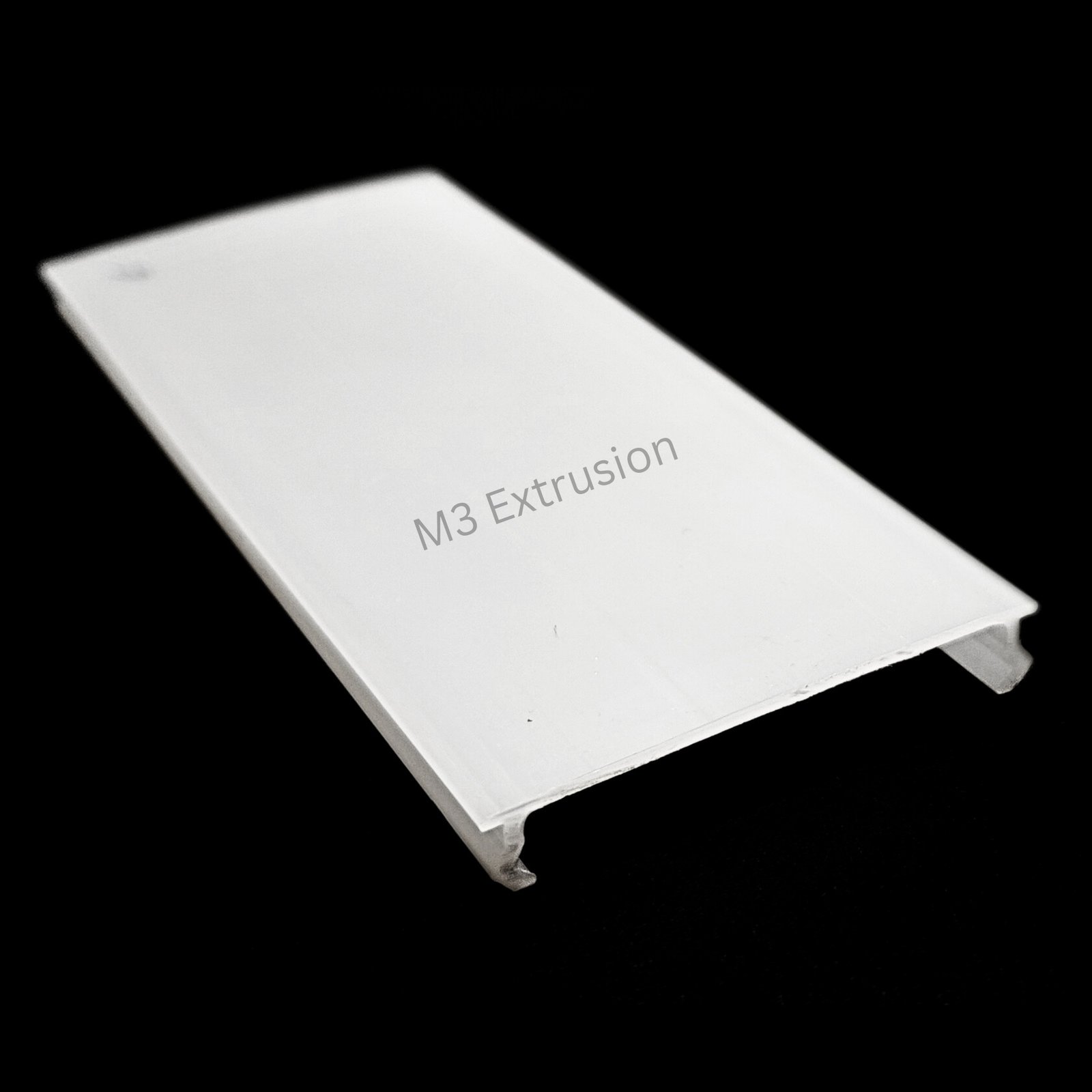

Another advantage of PVC is that it is highly customizable, allowing manufacturers like M3 Extrusion to produce thermal break profiles tailored to the specific needs of a building project. Whether for windows, doors, or curtain wall systems, PVC thermal breaks can be designed to provide maximum protection against moisture and mold while maintaining the aesthetic appeal of the structure.

Long-Term Benefits of PVC Thermal Breaks

The advantages of installing PVC thermal breaks extend far beyond just moisture and mold prevention. By improving the energy efficiency of a building, these profiles also help to reduce heating and cooling costs. This leads to long-term savings for building owners and contributes to the overall sustainability of the property.

Moreover, by preventing moisture-related damage such as rot, rust, or mildew, PVC thermal breaks help extend the lifespan of the building’s materials. Windows, doors, and other structural components that are protected from moisture and mold will remain in good condition for a much longer period, reducing the need for costly repairs and replacements.

Installation and Maintenance

Installing PVC thermal breaks is relatively straightforward for experienced professionals, and they can be incorporated into a variety of building projects, from residential homes to large commercial properties. It is important to ensure that the thermal insulation components are installed correctly to maximize their effectiveness in preventing heat loss and moisture buildup.

Once installed, PVC thermal breaks require very little maintenance. Unlike some materials that may need frequent checks or repairs, PVC profiles are durable and resistant to wear and tear. A simple cleaning routine is typically all that is needed to keep them in top condition.

Why Choose M3 Extrusion for Your Thermal Break Needs?

When it comes to high-quality PVC thermal insulation components, M3 Extrusion is a trusted name in the industry. Known for its commitment to precision manufacturing and top-tier materials, M3 Extrusion offers thermal insulation components that are both effective and durable. Their products are designed to meet the highest standards of performance and sustainability, ensuring that your building stays protected from moisture, mold, and heat loss for years to come.

Whether you’re building a new structure or upgrading an existing one, choosing the right thermal insulation components is key to achieving the best possible results. With Us, you can rest assured that you’re investing in a solution that delivers long-lasting protection for your building and its occupants.

Conclusion

In conclusion, PVC thermal breaks are an essential component in the fight against moisture and mold in buildings. By preventing heat transfer and reducing the risk of condensation, these profiles protect against moisture buildup that can lead to costly damage and health concerns. With their energy efficiency benefits and long-term durability, PVC thermal breaks are a smart choice for anyone looking to enhance the performance and longevity of their property.

If you’re looking for a reliable, cost-effective solution to moisture and mold problems, consider incorporating PVC thermal breaks into your next building project. And for the highest quality products, M3 Extrusion is here to provide the ideal thermal break profiles for your needs.