In today’s fast-moving industrial world, rigid PVC profiles are becoming a common choice in plants and manufacturing facilities for frames, panels, support components, and other industrial parts.

Made from polyvinyl chloride formed into fixed cross-section shapes through an extrusion process, rigid PVC profiles are solid plastic sections designed for consistent industrial use. In rigid PVC extrusion in India, these profiles are produced without added plasticisers, which gives them a firm structure suitable for precision applications.

They are manufactured in standard and custom shapes to meet different design and fit needs. This allows industries to use them as structural sections, covers, channels, and guides across many systems.

The extrusion process helps maintain uniform size, which is a key reason durable PVC extrusion for industrial use supports proper assembly and reliable performance.

Rigid PVC profiles are used in environments where parts face moisture, cleaning agents, and daily wear.

The material does not rust or absorb water, which helps maintain part integrity over time. Their smooth surface also allows easy cleaning and simple upkeep.

As industries look for materials that balance performance with cost control, rigid PVC profiles continue to see wider adoption across industrial applications.

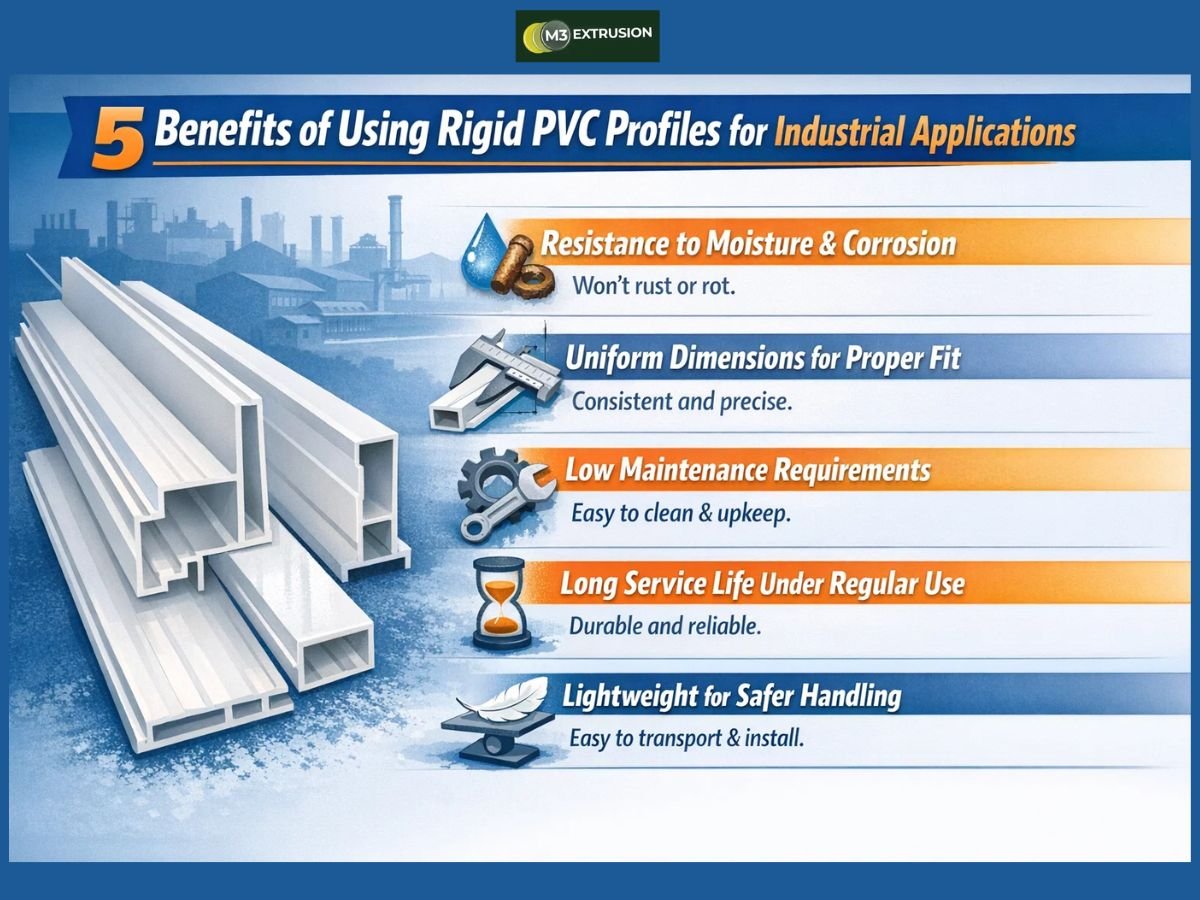

Top 5 Benefits of Rigid PVC Profiles for Industrial Use

Rigid PVC profiles are being widely used across industries because of their balanced performance and ease of use. Their ability to adapt to different production needs makes them suitable for varied industrial setups. Manufacturers value materials that support smooth workflows without adding extra handling steps, and rigid PVC profiles fit well into this approach.

These profiles also help maintain consistency during ongoing operations. Once installed, they continue to perform without frequent adjustments, which supports stable output. Their surface finish allows parts to stay clean and presentable even in busy work areas.

Storage and movement within facilities remain simple due to their manageable weight as well as shape. This supports faster internal logistics and reduces effort during handling. Teams can organize and replace components without complex tools or added training.

Rigid PVC profiles help reduce unplanned stoppages caused by worn or damaged parts. This allows production teams to keep schedules on track with fewer material-related delays.

Here are five benefits of rigid PVC profiles for industrial use:

Resistance to Moisture and Corrosion

One of the major benefits of rigid PVC profiles is their ability to resist moisture and corrosion in industrial environments. Unlike wood or metal, rigid PVC profiles do not absorb water or react to damp conditions and this helps parts stay stable during regular use.

- Prevents water damage: Rigid PVC profiles do not swell, rust, or weaken when exposed to moisture, which helps maintain part integrity in wet or humid areas.

- Handles chemical exposure: These profiles resist many common oils, cleaners, and chemicals found in industrial spaces, reducing surface damage over time.

- Avoids surface breakdown: Rigid PVC profiles do not flake, pit, or degrade when exposed to damp conditions, which helps surfaces stay intact and functional during long-term industrial use.

By resisting moisture and corrosion, rigid PVC profiles remain reliable in demanding conditions and support longer service life in industrial applications.

Uniform Dimensions for Proper Fit

In addition to resisting moisture as well as corrosion, rigid PVC profiles also maintain uniform dimensions that support proper fit across industrial assemblies. Consistent sizing helps parts align correctly during installation and remain stable during regular operation.

- Supports accurate assembly: Uniform dimensions in rigid PVC profiles allow components to fit together as intended, reducing gaps, misalignment and on-site adjustments.

- Improves production consistency: Rigid PVC profiles produced to consistent sizes help maintain steady quality across batches, which supports repeatable results in industrial setups.

- Limits rework and waste: Proper fit of rigid PVC profiles reduces cutting, reshaping, or replacement during installation, which helps save time and material.

Because of their uniform sizing, rigid PVC profiles fit correctly and perform steadily within industrial assemblies.

Low Maintenance Requirements

When compared to metal or wood components, rigid PVC profiles require far less maintenance in industrial environments. They do not need painting, coating, or regular surface treatment to stay functional during daily use.

- Avoids surface treatment: Rigid PVC profiles do not require painting or protective coatings, which reduces routine upkeep work.

- Resists wear during cleaning: The material handles regular washing and cleaning without surface damage or breakdown.

- Limits repair needs: Rigid PVC profiles maintain performance without frequent fixes, which helps reduce downtime.

Lower maintenance needs allow rigid PVC profiles to remain in service longer while keeping upkeep effort and costs under control.

Long Service Life Under Regular Use

Under regular industrial conditions, rigid PVC profiles continue to perform without early failure or loss of function. Their stable structure helps them handle daily use while maintaining fit and performance over time.

- Handles repeated use: Rigid PVC profiles withstand ongoing operational stress without cracking or deforming easily.

- Resists gradual wear: The material holds up against friction and contact, which helps parts stay usable for longer periods.

- Supports steady output: Consistent performance over time helps reduce interruptions linked to part failure.

With extended service life, rigid PVC profiles help industries maintain reliable operation while limiting downtime caused by part wear or early failure.

Lightweight for Safer Handling

Unlike steel, aluminium, or cast metal components used in industrial settings, rigid PVC profiles offer a lightweight option that is easier and safer to handle during installation and routine work. Reduced weight helps lower physical strain and supports faster movement within facilities.

- Eases manual handling: Rigid PVC profiles can be lifted and positioned with less effort, which helps reduce strain on workers.

- Improves installation speed: Lighter components allow quicker placement and adjustment during assembly.

- Supports safer work areas: Reduced handling weight lowers the risk of drops, slips or handling-related injuries.

Lighter weight makes rigid PVC profiles easier to manage while supporting safer and more efficient industrial operations.

Rigid PVC profiles offer a dependable option for use in factories and manufacturing facilities where steady performance and ease of handling matter. Their resistance to moisture, consistent dimensions, low maintenance needs, and long service life support smooth daily operation. Lightweight handling also improves safety during installation and routine work. Together, these benefits help reduce downtime, limit replacement needs and keep production running without added complexity.

Rigid PVC profiles offer a dependable option for use in factories and manufacturing facilities where steady performance and ease of handling matter. Their resistance to moisture, consistent dimensions, low maintenance needs as well as long service life support smooth daily operation.

Lightweight handling also improves safety during installation and routine work. Together, these benefits help reduce downtime, limit replacement needs, and keep production running without added complexity.

Are you looking to buy rigid PVC profiles in India? M3 Extrusion manufactures durable, high-performance rigid PVC profiles for a wide array of industries, offering reliable parts, steady quality, and tailored solutions to help you get the right fit for your project.

Frequently Asked Questions

Why do industries choose rigid PVC profiles over metal or wood?

Industries often choose rigid PVC profiles because they do not rust, rot, or absorb water. They are lighter to handle, easier to fabricate, and require less upkeep during long-term industrial use.

Are rigid PVC profiles suitable for harsh industrial environments?

Rigid PVC profiles perform well in environments with moisture, oils, and common cleaning agents. Their resistance to corrosion and surface damage helps them maintain performance in demanding industrial conditions.

Do rigid PVC profiles require regular maintenance?

Rigid PVC profiles generally require minimal maintenance. They do not need painting or coating and can be cleaned easily, which helps reduce downtime and routine upkeep effort in industrial operations.

Can rigid PVC profiles be customised for specific industrial needs?

Rigid PVC profiles can be made in various shapes, sizes, and finishes. This allows manufacturers to match design requirements without extra fabrication steps or significant material waste.

Check related articles for more insights:

- Materials Used in Rigid PVC Profiles and Their Advantages

- How Rigid PVC Profiles Improve Efficiency and Sustainability in Building.

- Why Rigid PVC Profiles are a Cost-Effective Solution for Indian. Manufacturers

- Top Applications of Rigid PVC Profiles in the Indian Construction Industry.