Infrastructure projects require materials that balance durability, cost efficiency, and flexibility. Traditional options like wood, aluminium, or steel serve many purposes but often create long-term issues with weight, corrosion, or maintenance. Today, many industries are turning to extruded plastic profiles in India to overcome these challenges.

Plastic extrusion produces consistent, durable profiles that can be supplied in bulk and customised for different requirements. From large-scale construction projects to industrial utilities, these profiles solve several ongoing challenges while ensuring reliability and cost savings.

Why Extruded Plastic Profiles Matter for Infrastructure

The demand for infrastructure materials has changed in recent years. Projects are bigger, more complex, and often under tighter budgets. Materials must be both strong and adaptable to different applications. Extruded plastic profiles fit this role because they are:

- Resistant to weather and corrosion

- Lightweight yet strong

- Easy to manufacture in large quantities

- Customisable for specific industrial needs

These advantages make them suitable for a wide range of uses, from housing and commercial buildings to transportation and utility systems.

Weather Resistance and Corrosion Control

Exposure to weather is one of the most common causes of material failure. Steel corrodes when exposed to moisture, while wood can warp, swell, or rot over time. These issues increase maintenance costs and reduce service life.

Extruded plastic profiles address this by being naturally resistant to water, humidity, and chemicals. They do not absorb moisture or degrade when exposed to sunlight and dust. This makes them an excellent choice for outdoor use in window frames, ducts, or external cladding.

Extruded plastic profiles resist corrosion, moisture, and heat, reducing the need for repainting, polishing, or protective treatments.

Reducing Structural Weight While Maintaining Strength

Heavy materials create practical challenges in infrastructure. They add to transport costs, require stronger support structures, and complicate installation. Plastic extrusion offers a solution by producing profiles that are lightweight but still durable enough to handle stress.

For example, in transportation systems such as metro stations or bus terminals, lightweight plastic sections reduce the load on supporting structures while providing the necessary strength. In housing, plastic frames replace heavier metals without compromising durability.

For more insight into material performance, see how extrusion technology offers solutions for enhancing strength without increasing weight in plastic profiles.

Design Flexibility and Customisation

Infrastructure often requires precise components that match specific design standards. Traditional materials like metal and wood are harder to shape into complex forms, which can limit options for architects and engineers.

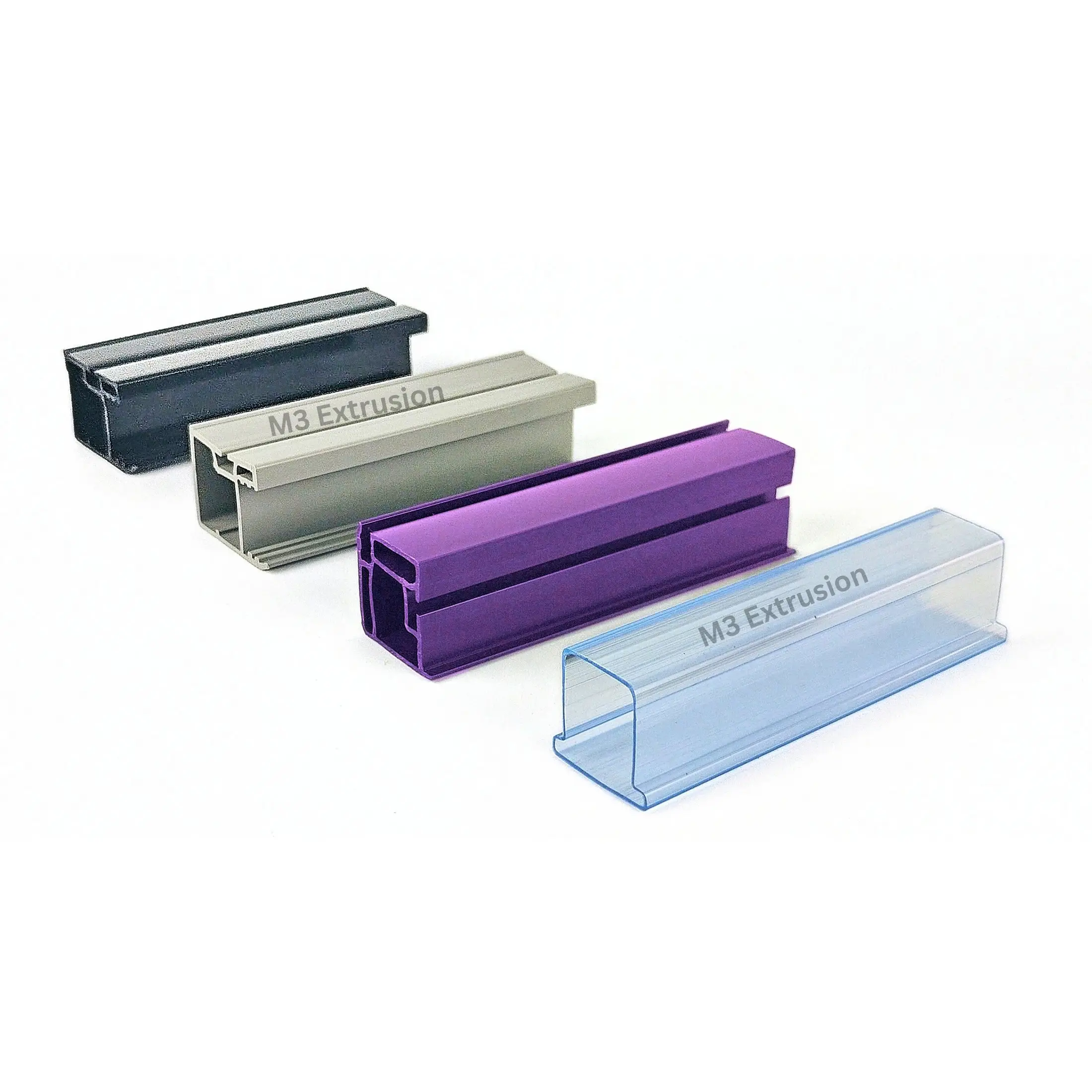

Plastic extrusion makes it easier to create profiles with custom dimensions, shapes, or finishes. Profiles can be designed to fit unique project requirements, whether for sealing systems, panels, or decorative applications. Bulk production further ensures that all components are uniform, which is important for maintaining consistency in large-scale projects.

Extruded plastic profiles can be customised into complex designs, providing flexibility for architects, builders, and manufacturers.

Cost Efficiency in Bulk Supply

Cost control is one of the biggest concerns in infrastructure projects. A material might perform well, but if it drives up expenses over time, it becomes less practical. Plastic extrusion provides cost advantages both during installation and throughout the material’s lifecycle.

- Installation is faster because of the lightweight nature of the profiles.

- Maintenance costs are lower due to resistance to damage and corrosion.

- Bulk orders reduce the cost per unit while ensuring supply for large projects.

Example: Housing developers often purchase thousands of identical PVC frames for windows and doors. Bulk supply ensures uniform quality and reduces costs significantly compared to sourcing wood or metal.

Durability and Long-Term Performance

Durability is key in infrastructure because replacements disrupt projects and add costs. Extruded plastic profiles are highly durable, resisting scratches, impact, and exposure to chemicals. Unlike wood or metal, they do not require regular repainting or surface treatments.

- In industrial settings, ducts and cable channels made from plastic extrusion perform reliably even under demanding conditions.

- In residential projects, PVC frames can last for decades without warping or corroding.

Extruded plastic profiles provide long service life with minimal upkeep, making them a reliable choice for infrastructure applications.

Additional Advantages for Modern Projects

Beyond the five main challenges, extruded plastic profiles also support sustainability. Many can be produced from recyclable materials, which helps reduce environmental impact.

Another benefit is ease of handling. Because profiles are lighter, they reduce the need for specialised tools or heavy machinery during installation. This not only lowers costs but also increases safety for workers on site.

Manufacturers such as M3 Extrusion supply extruded profiles on order, allowing industries to maintain quality control while meeting bulk requirements. This capability supports both small projects and large-scale infrastructure developments.

Practical Applications in Infrastructure

Extruded plastic profiles are now commonly used in:

- Windows and doors: Rigid PVC frames provide long-lasting strength without warping.

- Cable management: Channels and ducts protect wiring in residential and industrial settings.

- Partitions and panels: Lightweight yet durable sections are ideal for temporary or permanent partitions.

- Shutters and enclosures: Rolling shutters and protective panels maintain performance with minimal upkeep.

By serving these applications, plastic extrusion continues to expand its role in modern infrastructure.

FAQs on Extruded Plastic Profiles

Q1. What are the main uses of extruded plastic profiles in infrastructure?

They are used in frames, ducts, shutters, and sealing systems. Their strength and resistance to corrosion make them suitable for construction, transport, and utilities.

Q2. Why choose plastic extrusion over metal or wood?

Plastic extrusion provides lightweight, durable, and corrosion-resistant profiles. Unlike metal or wood, they require less maintenance and are easier to customise.

Q3. Can extruded plastic profiles handle high-impact environments?

Yes. Modern plastic profiles are engineered to resist scratches and impact, making them reliable for heavy-use areas such as industrial floors or partitions.

Q4. Are plastic extrusion profiles cost-effective for bulk projects?

Yes. Bulk manufacturing ensures consistency and reduces per-unit costs. This makes them highly suitable for large infrastructure developments.

Q5. Do extruded plastic profiles support sustainability goals?

Yes. Many are produced using recyclable materials, reducing environmental impact while still offering strength and long-term performance.

Conclusion

Modern infrastructure requires materials that are strong, adaptable, and cost-efficient. Extruded plastic profiles provide solutions to some of the biggest challenges in construction and industrial projects, including weather resistance, weight control, customisation, cost efficiency, and durability. By addressing these needs, they ensure long-lasting performance and reliable results for industries across India.