When industries choose materials for projects, one factor always matters: long-term cost. While the upfront price is important, what truly affects profitability is the money spent on repairs, replacements, and upkeep over the years. This is where rigid PVC extrusion in India has gained popularity. Businesses across construction, interiors, and industrial applications rely on extruded PVC profiles because they last longer, require less maintenance, and perform consistently under tough conditions.

Rigid PVC is not only strong but also versatile. It can be manufactured in bulk, shaped into different profiles, and customised for specific uses. By reducing the need for constant servicing, it helps companies save money and resources in the long run.

Why Maintenance Costs Impact Profitability

Every building, factory, or system demands upkeep. Regular repairs, repainting, or replacing damaged parts create ongoing expenses. For businesses working on large projects or supplying materials in bulk, these costs multiply. Choosing a material that performs well over decades instead of years makes a direct difference to overall project success.

Rigid PVC extrusion addresses these challenges by combining:

- Strength and durability against stress and wear

- Resistance to moisture, corrosion, and chemicals

- Flexibility in design for different industrial and commercial needs

Let’s break down the five main ways rigid PVC extrusion reduces long-term maintenance costs.

Resistance to Weathering and Corrosion

Weather is one of the biggest reasons for material damage. Metals rust when exposed to rain and humidity. Wood swells, warps, or rots under moisture and pests. Rigid PVC extrusion solves these problems by offering natural resistance to environmental factors.

- Construction example: Window and door frames made of rigid PVC remain stable even after years of exposure to heat, monsoons, and dust. Unlike wooden frames, they don’t need repainting or termite treatment.

- Industrial example: PVC ducts, pipes, and enclosures do not corrode when exposed to water or chemicals, which makes them suitable for factories and processing units.

Rigid PVC resists water, sun, and corrosion, reducing the need for repainting, polishing, or protective treatments.

Durability in Heavy-Use Environments

In places where there is constant movement or impact, materials must withstand heavy wear. Rigid PVC profiles are engineered to retain strength under pressure. They resist cracking, denting, or deforming, which means fewer replacements.

- Retail shutters: PVC rolling shutters operate smoothly and last longer without rust or dents compared to traditional metal shutters.

- Warehouse partitions: Using rigid PVC for partitions reduces the need for frequent repairs, especially in areas with forklift or machinery traffic.

Durability translates into fewer breakdowns, fewer service calls, and reduced downtime — all of which lower hidden maintenance expenses.

Easy Cleaning and Low Upkeep

Maintenance is not just about major repairs; it also includes day-to-day upkeep. Surfaces that require regular polishing, painting, or specialised cleaning increase labour costs. Rigid PVC avoids this by being simple to clean.

- Its smooth surface prevents dust, grime, or grease from sticking.

- A basic wipe with water and mild detergent keeps it hygienic.

- No special coatings or chemicals are required.

This feature makes it popular in healthcare, retail, and food processing industries, where hygiene standards are strict but budgets must be managed efficiently.

Rigid PVC requires only basic cleaning, reducing both time and money spent on maintenance.

Cost-Efficient Installation and Replacement

One often-overlooked factor in long-term savings is the installation process. Heavy materials like steel or wood demand special tools, additional labour, and more time to fit. Rigid PVC is lightweight yet strong, which simplifies installation.

- Construction companies save labour costs as PVC frames and profiles can be installed faster.

- Manufacturers benefit from modular PVC systems, where a damaged profile can be swapped without disturbing the rest of the structure.

Because installation is easier, the overall project cost decreases. And when replacement is needed, it doesn’t create major downtime.

Rigid PVC cuts costs with quick installation and easy replacement, especially in bulk industrial projects.

Long Life Cycle and Extended Performance

Perhaps the strongest reason businesses choose rigid PVC extrusion is its longevity. Profiles manufactured with high-quality PVC can last for decades without losing shape or strength. The longer a material stays functional, the fewer times it needs repair or replacement.

- Housing projects often use rigid PVC door and window frames because they remain sturdy for years, unlike wood that may need replacement after 5–10 years.

- Factories and warehouses prefer PVC ducts and channels that stay reliable even in demanding environments.

This extended lifecycle creates significant savings for businesses, especially when multiplied across large orders or multiple sites.

Beyond Maintenance: Added Value of Bulk Supply

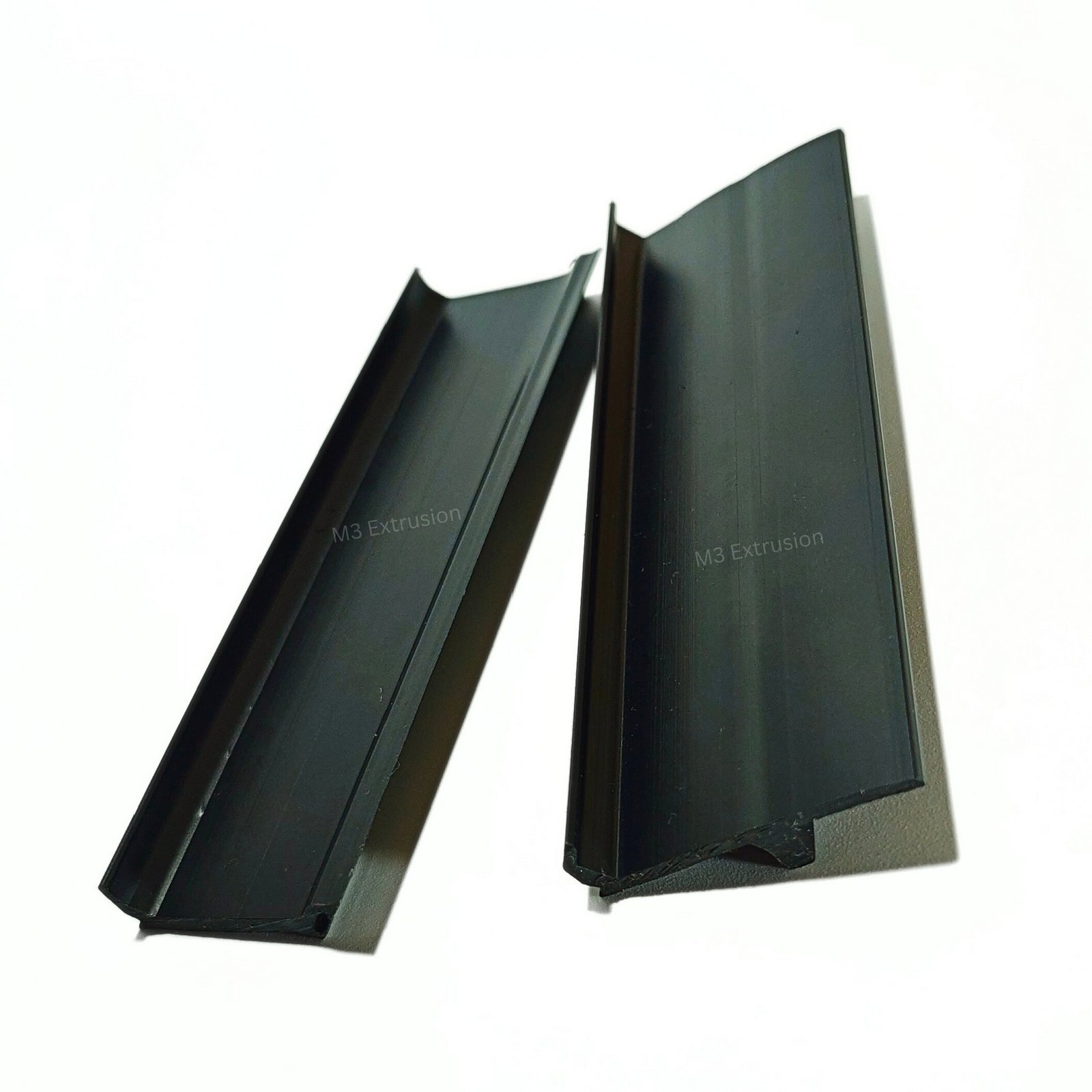

Rigid PVC extrusion is not just about durability. For B2B buyers, bulk availability and consistency are just as important. Manufacturers like M3 Extrusion provide extrusion profiles on order, ensuring:

- Consistent quality across thousands of pieces

- Standardised dimensions for large projects

- Reliable delivery schedules for industrial buyers

This makes rigid PVC a practical choice not only for reducing maintenance but also for ensuring smooth supply chain operations.

For industries looking at more design flexibility, custom plastic profiles can solve design and durability challenges. This expands the value of extrusion technology beyond standard profiles into specialised solutions.

FAQs on Rigid PVC Extrusion and Maintenance

Q1. What makes rigid PVC more reliable than wood or metal?

Rigid PVC does not rot, rust, or absorb water. Unlike wood that needs termite protection or metal that requires anti-rust coating, PVC stays strong for years with very little maintenance.

Q2. Can rigid PVC profiles handle outdoor conditions?

Yes. Rigid PVC extrusion is weather-resistant, making it suitable for outdoor frames, shutters, and ducts. It does not warp in heat, swell in rain, or corrode in humidity.

Q3. How cost-effective is rigid PVC for bulk buyers?

When purchased in bulk, rigid PVC becomes even more cost-effective because it reduces installation, repair, and long-term replacement costs, offering strong returns on investment.

Q4. Do rigid PVC profiles require frequent replacement?

No. High-quality PVC extrusion profiles last decades depending on the application. Replacements are far less frequent compared to wood or metal alternatives, reducing ongoing project costs.

Q5. What cleaning methods are needed for rigid PVC profiles?

Cleaning is simple. Most rigid PVC products only need a wipe with water or mild detergent. No expensive chemicals or special tools are required, keeping upkeep affordable and quick.

Conclusion

Rigid PVC extrusion is more than just a strong material; it is a long-term solution for reducing maintenance costs across industries. By resisting weather damage, providing durability under stress, simplifying cleaning, and lowering installation expenses, it ensures businesses spend less over the lifecycle of their projects.