PVC window profile extrusion has become a cornerstone in modern industrial window systems. Manufacturers in India and worldwide rely on this technology to deliver durability, energy efficiency, and design flexibility. For industrial facilities, choosing the right extrusion method can significantly reduce maintenance costs while ensuring long-lasting performance. In this blog, we explore six key applications where PVC window profile extrusion in India plays a vital role.

Why PVC Window Profile Extrusion Matters

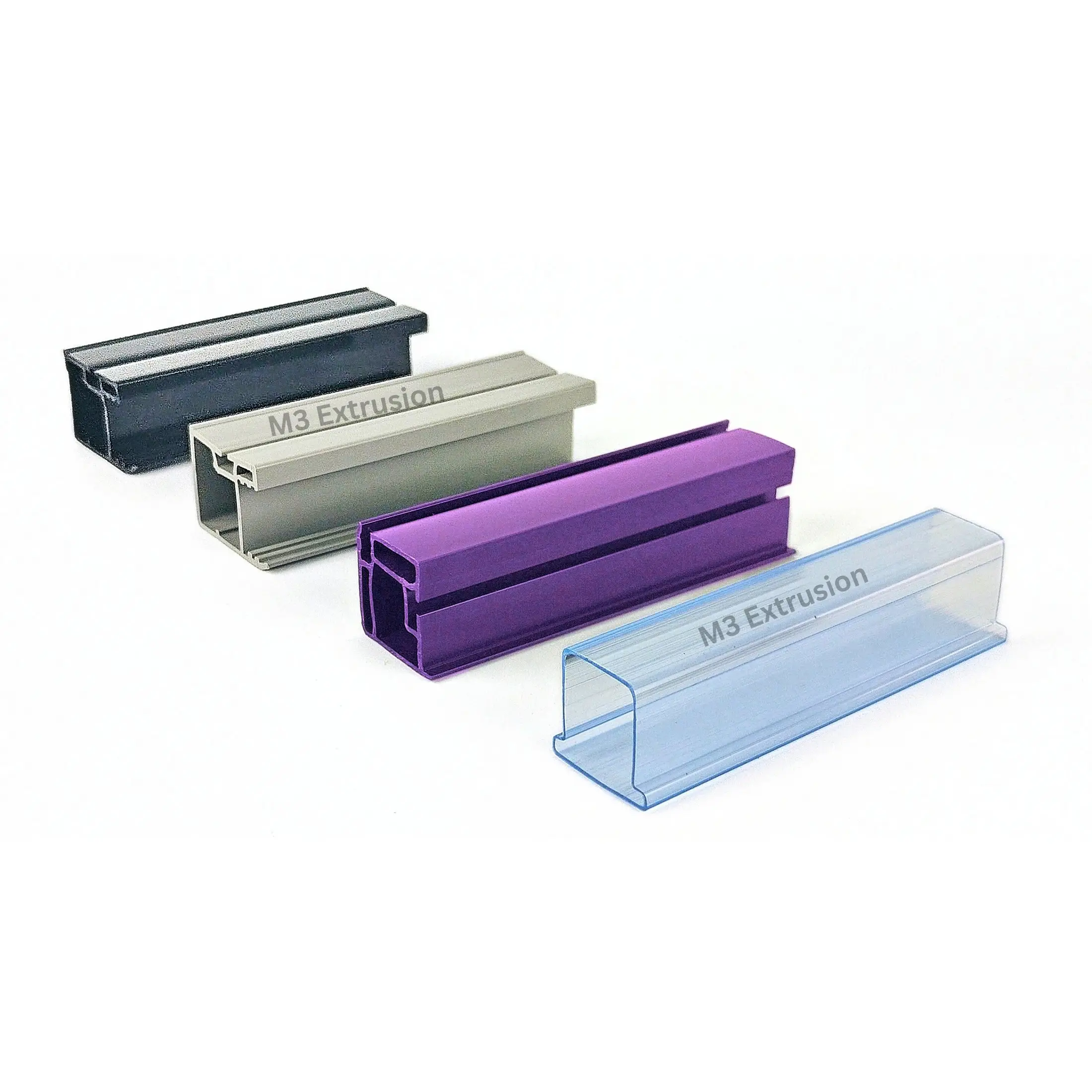

PVC (Polyvinyl Chloride) profiles are widely used for window frames due to their strength, versatility, and resistance to environmental factors. Extrusion allows manufacturers to shape PVC into precise designs tailored to industrial needs. Using high-quality PVC window profile extrusion can:

- Provide enhanced insulation against heat and sound.

- Reduce long-term repair and replacement issues.

- Ensure consistency in large-scale production for industrial projects.

For strategies on reducing repair and replacement issues with PVC window profiles, detailed insights are available on M3 Extrusion’s site.

1. Factory and Industrial Facility Windows

Industrial facilities often require windows that withstand dust, chemicals, and constant use. PVC window profiles offer:

- Corrosion resistance for chemical-heavy environments.

- Easy-to-clean surfaces that minimise maintenance.

- Strong structural integrity for large window panes.

These features make PVC extrusion a practical choice for factory and warehouse windows, where durability is essential.

2. Energy-Efficient Office and Commercial Spaces

Modern commercial buildings demand energy efficiency to reduce operational costs. PVC window profile extrusion in India helps achieve this by:

- Creating airtight seals that limit heat transfer.

- Reducing energy consumption for cooling and heating.

- Supporting double and triple-glazing applications for industrial offices.

Energy-efficient window systems not only save costs but also contribute to sustainability goals, making PVC profiles a practical choice for industrial-commercial hybrids.

3. Cold Storage and Refrigeration Units

Cold storage facilities require windows that maintain strict temperature controls. PVC extruded profiles are suitable because they:

- Minimise thermal bridging, preventing heat loss or gain.

- Resist moisture and condensation issues over time.

- Provide stable frames for large glass panels in refrigerated spaces.

The precision of extrusion ensures that each frame meets strict industrial standards for temperature control.

4. Cleanrooms and Laboratories

Laboratories and cleanrooms demand contaminant-free environments. PVC window profiles enhance these spaces by:

- Offering smooth, easy-to-clean surfaces.

- Providing airtight and secure seals to control airflow.

- Withstanding repeated cleaning with chemicals and disinfectants.

These properties make PVC extrusion ideal for industries like pharmaceuticals, electronics, and food processing.

5. Industrial Warehouses and Logistics Hubs

Warehouses face challenges such as high traffic, impact from equipment, and exposure to dust. PVC window profiles help by:

- Reducing the risk of frame damage from mechanical impacts.

- Maintaining insulation in temperature-sensitive storage areas.

- Supporting large-scale installations with consistent quality from extrusion.

This ensures windows remain functional and safe, reducing the need for frequent replacements.

6. Educational and Institutional Buildings

Schools, universities, and training centres with industrial setups require durable window systems. PVC window profile extrusion provides:

- Resistance to wear and tear from heavy usage.

- Low maintenance requirements over long periods.

- Flexible designs suitable for large or irregularly shaped windows.

These advantages make PVC extrusion a reliable option for educational institutions seeking long-term efficiency.

Key Benefits of Using PVC Window Profile Extrusion

Using PVC window profiles in industrial applications delivers measurable benefits:

- Durability: Resistant to weather, chemicals, and heavy usage.

- Cost Efficiency: Lower maintenance and reduced repair needs.

- Design Flexibility: Supports varied window shapes and sizes.

- Energy Efficiency: Reduces heating and cooling costs.

- Safety: Stable frames for heavy glass panels.

M3 Extrusion provides a range of solutions for industrial clients looking to integrate PVC window profile extrusion in India while reducing long-term repair and replacement issues.

FAQ: PVC Window Profile Extrusion in Industrial Settings

- What is PVC window profile extrusion?

PVC window profile extrusion is a manufacturing process where PVC material is melted and shaped into precise window frame designs, offering durability and consistency for industrial and commercial applications. - Why is PVC used for industrial windows?

PVC is strong, resistant to corrosion and chemicals, and requires low maintenance. It supports energy-efficient glazing and long-lasting frames, making it ideal for industrial settings. - Can PVC window profiles withstand extreme weather?

Yes, extruded PVC profiles resist UV radiation, moisture, and temperature fluctuations, ensuring long-term performance in harsh climates. - How does extrusion reduce maintenance?

Extrusion ensures precise, uniform profiles that fit perfectly, reducing leaks, warping, and structural issues. - Are PVC windows energy efficient?

Extruded PVC profiles provide tight seals and support double or triple glazing, significantly reducing energy loss and lowering operational costs in industrial buildings. - Is PVC extrusion suitable for large-scale industrial projects?

Yes, extrusion produces uniform profiles ideal for bulk installations, ensuring consistent quality across multiple units and reducing installation time.

Conclusion

Industrial window systems benefit from PVC window profile extrusion in India through enhanced durability, energy efficiency, and low maintenance. From factories to laboratories, warehouses to educational institutions, PVC profiles provide reliable solutions that reduce long-term repair and replacement issues. Incorporating these extruded profiles ensures windows remain functional, secure, and cost-effective over time.