When construction firms look for ways to manage budgets without compromising performance, the choice of materials becomes critical. A warm edge spacer in India has emerged as one of the most effective solutions for glazing systems in large projects. These spacers not only improve insulation but also contribute to long-term financial savings. For developers and industrial buyers, understanding the full range of cost benefits can help in making better decisions that align with both operational and sustainability goals.

What Are Warm Edge Spacers?

A warm edge spacer is a strip placed between panes of glass in insulated glazing units (IGUs). It seals the gap while keeping the glass edges apart. Traditionally, aluminium was used for this purpose. However, aluminium is a highly conductive metal, which means it allows heat to pass through easily.

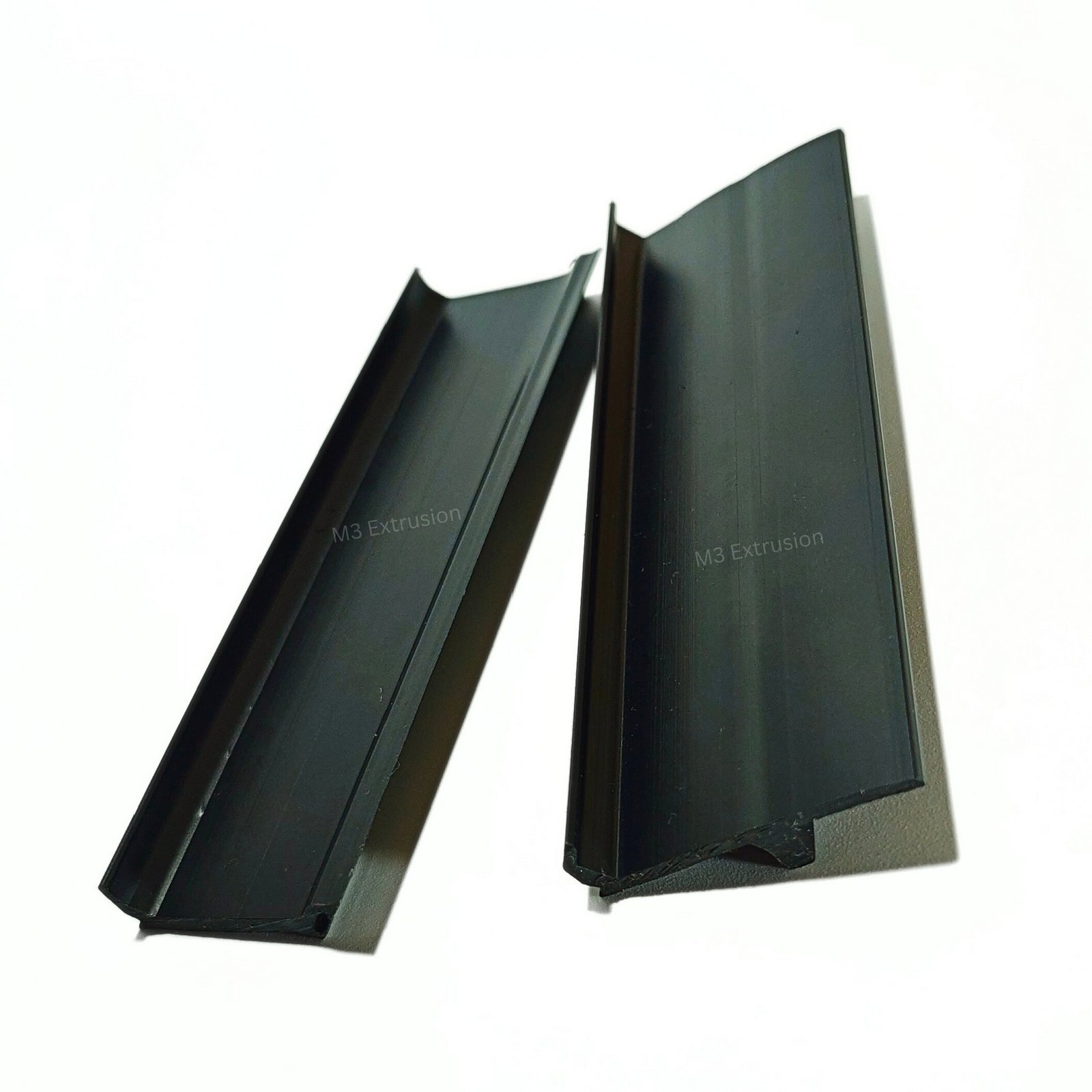

Warm edge spacers are different. They are usually made from:

- Stainless steel – stronger and less conductive than aluminium.

- Thermoplastic composites – flexible, durable, and excellent at resisting heat flow.

- Hybrid materials – combining polymers and thin metal for balance of strength and efficiency.

The result is a glazing unit that retains heat during winter, reduces cooling losses in summer, and prevents condensation on the edges. For large buildings with hundreds or thousands of windows, the cumulative savings can be substantial.

Why Warm Edge Spacers Are Cost-Effective in Large-Scale Construction

1. Reduced Energy Bills

The largest share of building operating costs often comes from heating and cooling. Windows are a weak point in any structure’s thermal envelope, especially at the edges. Warm edge spacers significantly reduce this thermal bridge.

- In a typical commercial tower, energy costs for air conditioning can account for 40–50% of operating expenses.

- Studies show warm edge spacers can reduce heat loss at the glass edge by up to 70% compared to aluminium.

Direct Answer: Warm edge spacers lower energy bills in large projects by improving insulation and cutting heating and cooling demands.

2.Longer Service Life of Glazing Units

Replacing glazing in high-rise or industrial buildings is both expensive and disruptive. Warm edge technology prevents premature failure by reducing condensation inside the units.

- Less moisture means seals last longer.

- Glass panes remain clearer, reducing the need for early replacement.

- Building owners benefit from extended product lifespans of 5–10 years longer than aluminium systems.

3.Improved Comfort Leads to Lower Operational Costs

Comfort is often underestimated as a cost factor. In offices, uneven temperatures lead to complaints, adjustments, and higher HVAC usage. By maintaining more stable interior temperatures, warm edge spacers create a balanced indoor environment.

- Employees are more productive when comfort levels remain steady.

- HVAC systems operate in smoother cycles, reducing electricity spikes.

- Over the lifespan of a building, the savings in operational efficiency can be significant.

4.Lower Risk of Condensation Damage

Condensation not only looks unattractive but also damages frames, walls, and flooring near windows. Repair costs in commercial or industrial buildings can run into thousands each year. Warm edge spacers keep the glass surface warmer, minimising condensation.

Key Cost Advantage: Reduced risk of mould, corrosion, and water-related damage to interiors and structures.

5.Compliance with Green Building Standards

Green certifications such as LEED (Leadership in Energy and Environmental Design) or IGBC (Indian Green Building Council) can increase the value of a property. Developers often use warm edge spacers to meet strict energy-efficiency requirements.

For investors, this means:

- Lower lifecycle energy consumption.

- Higher property resale value.

- Access to government incentives for sustainable construction in some regions.

6.Long-Term Financial Benefits

While aluminium spacers may appear cheaper initially, warm edge spacers generate decades of savings. Energy efficiency, reduced maintenance, and fewer replacements deliver a strong return on investment.

Learn more about the Long-Term Cost Benefits of Using Warm Edge Spacers in Construction.

Warm Edge Spacer in India: Market Growth and Applications

India’s construction industry is growing rapidly, especially in urban centres. According to recent studies, the demand for energy-efficient building materials in India is expected to grow at over 15% annually. This growth is driven by rising energy prices and stricter building codes.

Common applications of warm edge spacers include:

- Commercial complexes and IT parks – where thousands of windows can multiply energy savings.

- Industrial facilities – reducing the load on heavy cooling systems.

- Hospitals and schools – improving comfort in sensitive environments.

- Residential townships and luxury housing – where energy-efficient glazing adds property value.

Technical Insights: How Warm Edge Spacers Save Money

- Thermal Conductivity

- Aluminium: approx. 160 W/mK

- Stainless steel: approx. 16 W/mK

- Polymer composites: <1 W/mK

- Aluminium: approx. 160 W/mK

- This drastic reduction directly influences heating and cooling loads.

- Condensation Resistance Factor (CRF)

- Warm edge spacers improve CRF ratings by 10–20 points compared to aluminium.

- A higher CRF means fewer condensation-related issues.

- Warm edge spacers improve CRF ratings by 10–20 points compared to aluminium.

- Payback Period

- In many projects, the cost difference between aluminium and warm edge spacers is recovered within 3–5 years through energy savings alone.

- In many projects, the cost difference between aluminium and warm edge spacers is recovered within 3–5 years through energy savings alone.

Quick Comparison: Warm Edge Spacers vs Aluminium Spacers

Feature | Warm Edge Spacers | Aluminium Spacers |

Heat Conductivity | Low | High |

Energy Savings | Significant | Minimal |

Condensation Resistance | High | Low |

Durability | 5–10 years longer | Shorter |

Lifecycle Cost | Lower | Higher |

FAQs on Warm Edge Spacers

1. What is a warm edge spacer?

A warm edge spacer is a low-conductivity material placed between panes of glass in insulated glazing units. It improves insulation, reduces condensation, and lowers energy consumption compared to aluminium spacers.

2. Why are warm edge spacers used in India?

They are increasingly used in India due to rising energy costs and urban construction growth. Warm edge spacers help reduce air conditioning expenses, improve comfort, and meet green building requirements.

3. Do warm edge spacers increase project costs?

They may cost slightly more upfront, but warm edge spacers reduce operating expenses, improve glazing lifespan, and support certification goals. This leads to net savings over the life of a building.

4. How do warm edge spacers reduce condensation?

They maintain higher inner glass surface temperatures, which prevents moisture build-up at window edges. This reduces mould risk and avoids long-term damage to frames and interiors.

5. Are warm edge spacers suitable for industrial projects?

Yes. They are highly suitable for industrial projects where buildings face heavy cooling and heating loads. Their efficiency leads to major cost savings in energy-intensive operations.

Conclusion

Warm edge spacers provide a practical, cost-efficient solution for large-scale construction projects. From energy savings and reduced maintenance to compliance with green standards, their benefits go far beyond initial costs. For Indian developers, architects, and industrial buyers, warm edge technology offers a pathway to long-term savings, sustainability, and improved building performance.