In modern manufacturing, plastic components must combine strength, adaptability, and cost efficiency. One process that delivers all three is rigid PVC extrusion in India, which has grown into a reliable choice for industries such as construction, automotive, packaging, and electrical. Its design flexibility allows manufacturers to create everything from simple profiles to complex cross-sections, meeting both functional and aesthetic requirements with ease.

This article explores six key design flexibility benefits that make rigid PVC extrusion essential for large-scale manufacturing, along with practical insights into why it continues to dominate industrial applications.

1.Versatile Profile Shapes

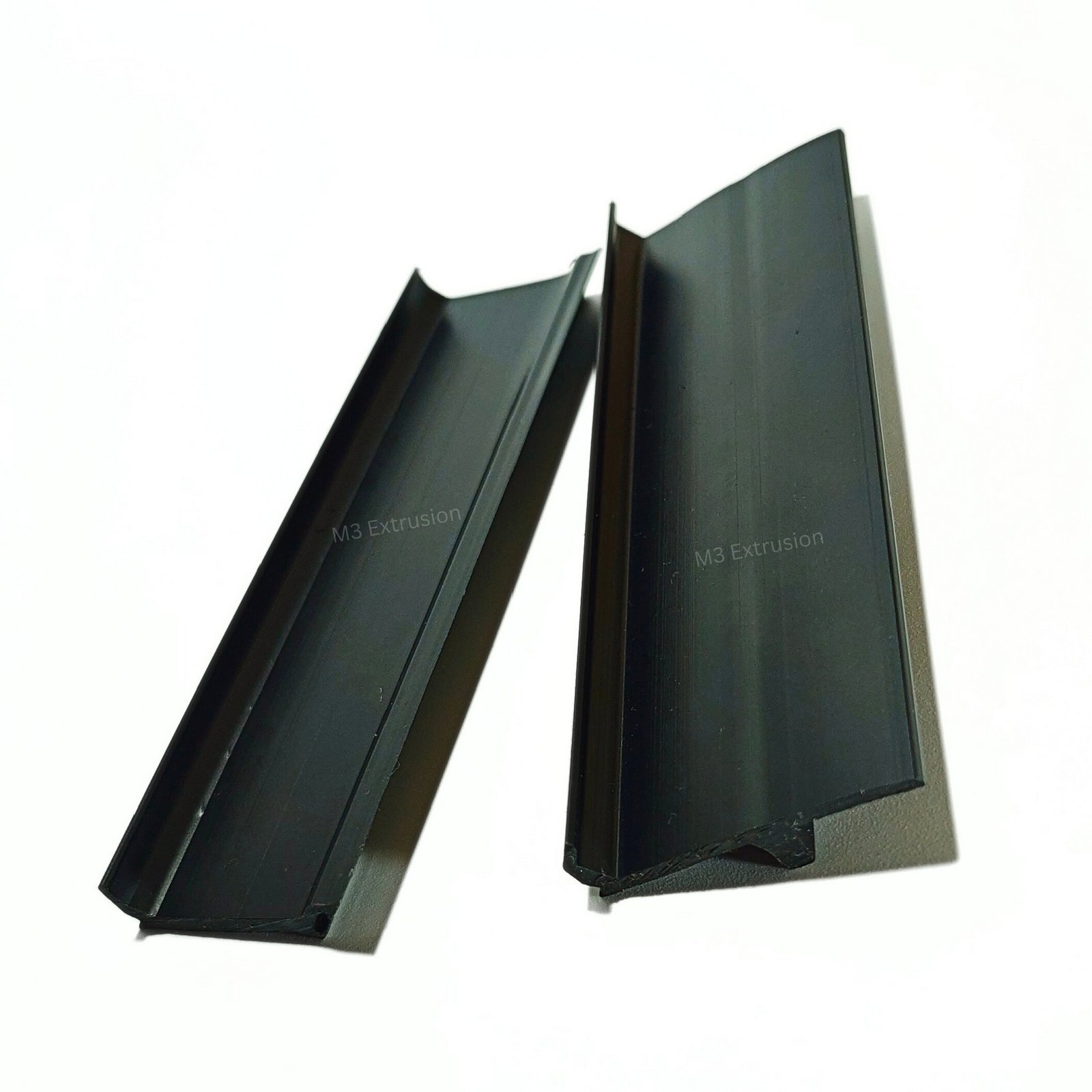

Rigid PVC extrusion allows manufacturers to create a wide variety of shapes and sizes, from simple rods and tubes to intricate profiles with complex geometries.

- Custom dies enable unique cross-sections for specific applications.

- Uniformity across long production runs ensures quality consistency.

- This adaptability reduces the need for secondary machining, saving both time and material.

For example, window and door frames produced with extrusion maintain precise dimensions that fit seamlessly during installation.

2. Integration of Functional Features

Manufacturers can integrate functional features directly into extruded designs, eliminating the need for extra assembly.

- Built-in channels for wiring or reinforcement.

- Snap-fit joints or locking mechanisms within the profile.

- Surface finishes, textures, and colour variations embedded during extrusion.

This level of integration makes rigid PVC profiles more efficient to use in construction, electronics, and packaging solutions.

3. Consistency in Bulk Production

Rigid PVC extrusion ensures high consistency across bulk manufacturing, which is vital for B2B buyers.

- Identical profiles across thousands of units.

- Dimensional stability even in long runs.

- Quality control embedded at each stage of extrusion.

For industries where interchangeable parts are required, such as piping systems or modular panels, this consistency reduces operational challenges.

4. Adaptability for Multiple Industries

The versatility of rigid PVC extrusion extends across multiple sectors:

- Construction: window frames, door profiles, wall panels.

- Electrical: cable ducts, conduits, insulation covers.

- Automotive: trims, protective strips, interior fittings.

- Industrial use: machine guards, structural profiles.

This adaptability demonstrates why extrusion remains the backbone of many large-scale projects.

5. Material Efficiency and Reduced Waste

Manufacturers benefit from the material efficiency of extrusion.

- Minimal trimming or post-production waste.

- Recyclable PVC can be reintroduced into the process.

- Controlled production ensures optimised material use.

This not only cuts costs but also supports sustainability efforts, which are increasingly important in global supply chains.

6. Long-Term Cost and Maintenance Benefits

One of the biggest advantages of rigid PVC extrusion is its contribution to reduced maintenance costs.

- Resistance to corrosion, rot, and chemical damage.

- Long service life compared to alternatives like wood or metal.

- Lower replacement frequency in large-scale projects.

For deeper insights, you can read about 5 Ways Rigid PVC Extrusion Reduces Long-Term Maintenance Costs.

Why Rigid PVC Extrusion Stands Out for Manufacturers

Rigid PVC extrusion offers the perfect balance of strength, flexibility, and cost-effectiveness. Its ability to combine design freedom with bulk supply makes it highly practical for manufacturers in India and abroad. The process ensures products are not only efficient to produce but also durable enough to perform under demanding conditions.

FAQs on Rigid PVC Extrusion

Q1. What is rigid PVC extrusion?

Rigid PVC extrusion is a process where polyvinyl chloride is heated and forced through a die to create solid, non-flexible profiles. These profiles are commonly used in construction, electrical, and industrial projects.

Q2. Why is rigid PVC extrusion in India popular in construction?

Rigid PVC extrusion in India is popular due to its strength, affordability, and weather resistance. It is widely used for doors, windows, and cladding, offering durability with lower long-term costs.

Q3. Can rigid PVC extrusion be customised?

Yes, manufacturers can customise rigid PVC extrusion into various shapes, finishes, and functional designs. This flexibility helps industries produce components that meet specific performance and design needs.

Q4. Is rigid PVC extrusion cost-effective for bulk supply?

Yes. The extrusion process is efficient, with low material waste and consistent production quality. This makes it highly suitable for bulk orders in industries like construction and electrical manufacturing.

Q5. How does rigid PVC compare to other materials?

Rigid PVC profiles are lighter than metal, more durable than wood, and resistant to corrosion, making them a reliable alternative across many industrial applications.

Conclusion

Rigid PVC extrusion provides manufacturers with unmatched design flexibility, bulk supply advantages, and long-term durability. Its ability to deliver custom shapes, functional integration, and consistent quality explains why it remains one of the most widely used manufacturing processes in India. For businesses looking to meet both performance and cost goals, rigid PVC extrusion is a proven solution that supports large-scale industrial success.