In modern manufacturing, precision and reliability are essential. Many industries in India are increasingly turning to custom plastic tube in India solutions to meet these demands. These tubes provide flexibility, durability, and cost-effectiveness, making them ideal for projects where accuracy is non-negotiable. From automotive components to medical devices and industrial machinery, custom plastic tubes ensure performance while reducing maintenance and operational challenges.

What Are Custom Plastic Tubes?

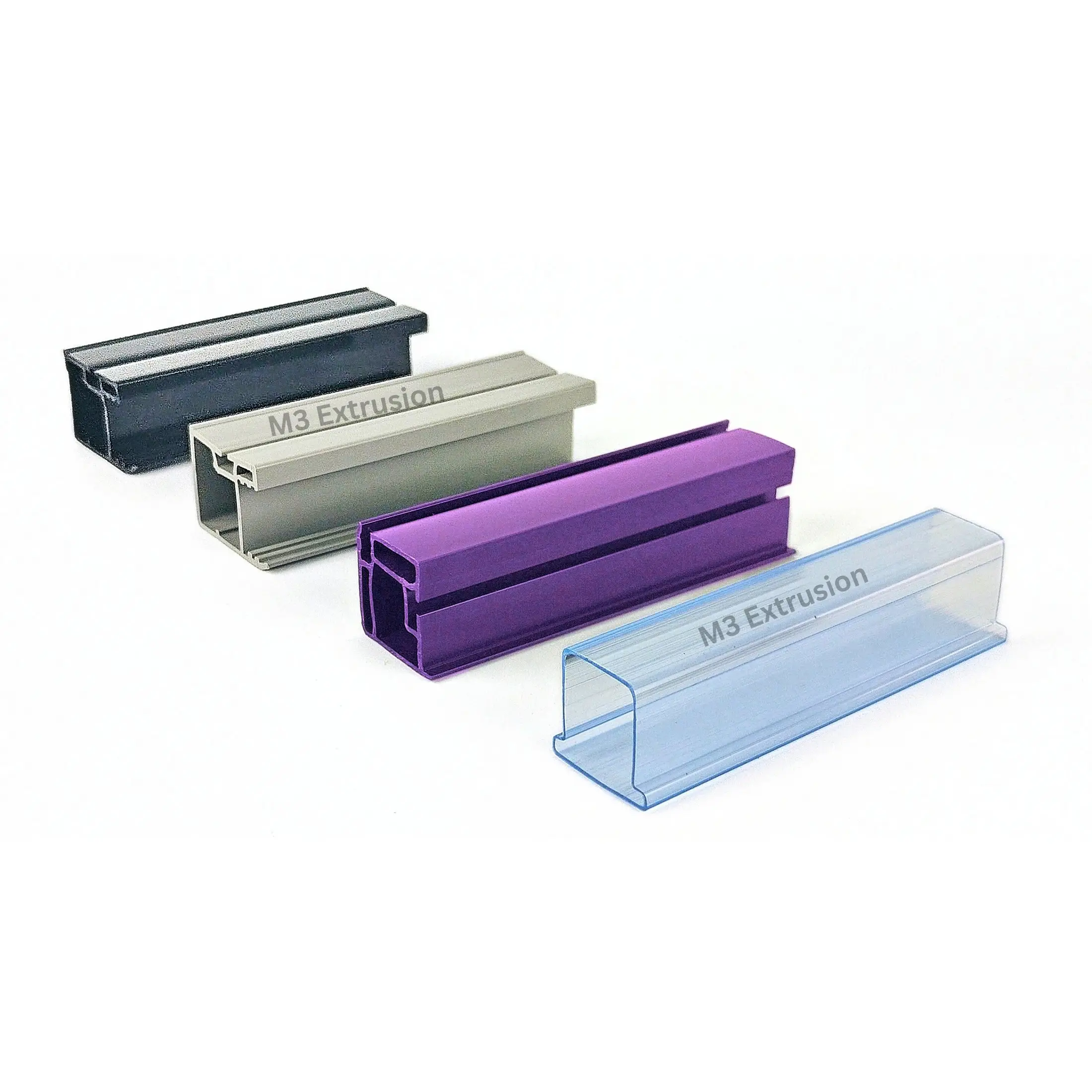

Custom plastic tubes are manufactured through processes like extrusion or injection molding to produce tubes of specific dimensions, materials, and properties. Unlike standard tubes, these are tailored to meet unique project requirements.

Key features include:

- Consistent inner and outer diameters for precision applications

- Flexibility in materials including PVC, ABS, and polycarbonate

- Ability to add colour, thickness, or chemical-resistant coatings for specialised use

These qualities make custom plastic tubes a dependable choice across industries where even minor deviations can impact project outcomes.

Why Manufacturers Prefer Custom Plastic Tubes

1. Precision and Accuracy

Custom plastic tubes are manufactured to exact specifications, ensuring that components fit perfectly in machinery, assembly lines, or industrial systems. This reduces errors and improves efficiency during installation and operation.

2. High Durability

Made from robust polymers, these tubes resist corrosion, impact, and chemical exposure. Industries such as chemical processing and pharmaceuticals rely on them because they maintain integrity under harsh conditions.

3. Lightweight and Easy to Handle

Compared to metal alternatives, plastic tubes are lightweight, reducing transportation costs and making installation easier. Despite their light weight, they provide adequate strength for most industrial applications.

4. Cost-Effective Production

Custom extrusion allows bulk production with minimal waste. Businesses benefit from lower manufacturing costs while still achieving precise dimensions and high-quality finishes.

5. Design Flexibility

Plastic tubes can be customised with specific diameters, wall thicknesses, and lengths. Manufacturers can also integrate features like ribbing, flanges, or flexible sections to solve unique engineering challenges.

6. Resistance to Environmental Factors

Custom plastic tubes resist moisture, UV radiation, and temperature variations, making them suitable for outdoor applications, industrial plants, and harsh climates commonly found in India.

7. Versatile Industrial Applications

Custom plastic tubes serve multiple sectors:

- Automotive: Fuel lines, cable covers, protective sleeves

- Medical and Pharmaceuticals: Sterile tubing for fluid transfer

- Construction: Conduits and protective channels for wiring

- Industrial Machinery: Fluid transfer, air ducts, and protective casings

This versatility explains why manufacturers across India are increasingly integrating custom plastic tubes into their precision projects.

Advantages Beyond Basic Applications

Long-Term Benefits Include:

- Lower maintenance needs due to resistance to corrosion and breakage

- Recyclable options available, supporting sustainability goals

- Consistent performance reduces downtime in production lines

- Lightweight materials decrease energy use for transport and handling

By choosing custom plastic tubes, manufacturers not only improve operational efficiency but also reduce costs and environmental impact.

Market Growth and Demand in India

India’s demand for custom plastic tube in India solutions is rising due to industrial expansion in sectors like automotive, pharmaceuticals, electronics, and infrastructure. With large-scale projects requiring bulk supply, manufacturers offering reliable, high-quality custom tubing are becoming essential partners.

Bulk procurement ensures consistent quality, lower costs per unit, and timely deliveries, which is critical for precision-dependent projects.

How M3 Extrusion Supports Manufacturers

At M3 Extrusion, we provide high-quality custom plastic tubes designed to meet industrial specifications. Our services include:

- Production of tubes in bulk and customised sizes

- Consistent quality with precise dimensions

- Flexibility to adapt to diverse industrial requirements

Partnering with a trusted manufacturer ensures that projects remain on schedule and achieve the desired outcomes without compromise.

FAQs on Custom Plastic Tubes

Q1. What materials are used for custom plastic tubes?

Common materials include PVC, ABS, and polycarbonate. Each material offers unique properties such as chemical resistance, flexibility, or high impact strength depending on the application.

Q2. Can custom plastic tubes handle high temperatures?

Yes. By selecting heat-resistant polymers or reinforced designs, tubes can withstand elevated temperatures common in industrial and automotive environments.

Q3. How are custom plastic tubes better than standard tubes?

They are designed to precise specifications, ensuring better fit, reliability, and performance. Standard tubes often lack the tolerance required for high-precision projects.

Q4. Are custom plastic tubes cost-effective for bulk orders?

Yes. Bulk production reduces per-unit costs and ensures consistent quality, making them highly suitable for large-scale industrial applications.

Q5. Can custom plastic tubes be used outdoors?

Absolutely. Many tubes are UV-resistant, moisture-proof, and durable in varying weather conditions, making them ideal for outdoor and industrial applications.