With the growing need for better insulation and improved energy efficiency in industrial windows, more and more factories and industrial units have started using warm edge spacers in their windows. Also known as thermal edge spacers, warm edge spacers are thin, non-metallic bars placed between panes of glass in double or triple-glazed windows. These warm edge spacers stop heat from escaping through edges, making windows better at keeping buildings warm.

7 Ways Warm Edge Spacers Reduce Heat Loss in Industrial Windows

Whether you want to improve energy efficiency in your factory building or simply want to keep your industrial unit warm during colder months, using warm edge spacers is vital. Not only do these warm edge spacers increase the durability of the windows, but they also improve insulation by reducing heat loss and preventing condensation around the edges.

Listed below are the seven ways warm edge spacers reduce heat loss in industrial windows.

Prevent cold spots on the glass surface– By keeping the edges of the windows properly insulated, warm edge spacers stop cold patches from forming on the glass, which helps keep the inside of the building warm and cosy.

Stop air movement between glass panes– In addition to preventing cold spots from forming on the glass surface, warm edge spacers also help seal the space between the glass panes to stop warm air inside from moving around and carrying heat away.

Maintain insulation in large glass areas– It goes without saying that larger windows have more surface area for heat to escape. These warm edge spacers help maintain strong insulation across these wide glass spans, which reduces heat loss in large industrial window systems.

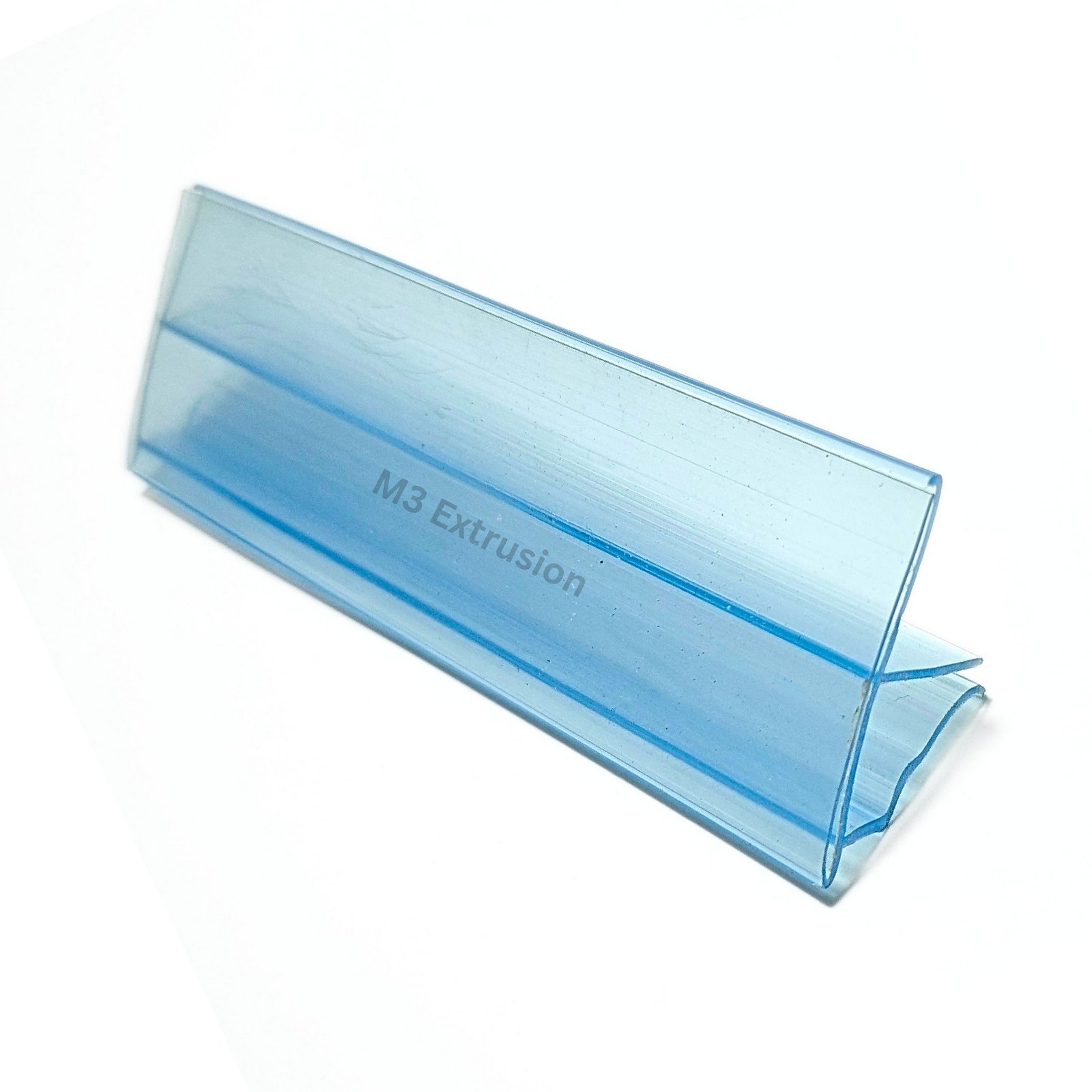

Lower thermal conductivity at window edges– Since warm edge spacers are made from low-conductivity materials like silicone foam, thermoplastic elastomers (TPE), etc., they significantly reduce heat transfer through the edge of the insulating glass unit, where heat loss typically occurs the most.

Keep the glass panes separated– In windows with two or three layers of glass, warm edge spacers keep the panes at the right distance. This prevents the heat from passing through the space between them.

Enhance durability- Warm edge spacers are made from flexible, corrosion resistant materials that hold up well in heat and humidity, preventing cracks and seal failures, which will decrease the life of that window insulation.

Absorb frame movement and prevent gaps– Warm edge spacers absorb expansion and contraction caused by temperature changes, which keeps the glass and frame tightly sealed to stop heat loss over time.

Reduce Heat Loss and Improve Energy Efficiency with Warm Edge Spacers

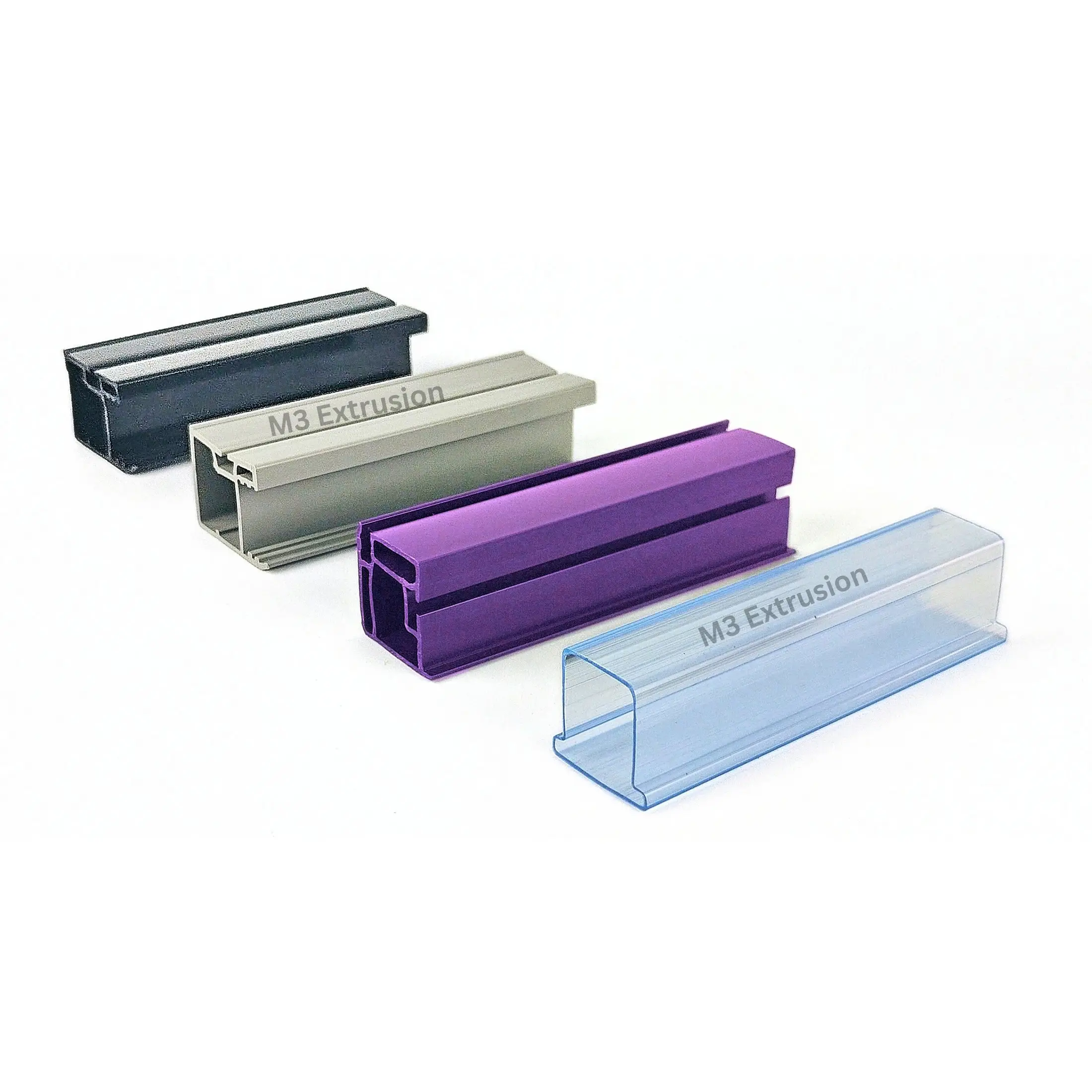

While these were some of the ways warm edge spacers reduce heat loss in industrial windows, there are many others, such as preventing seal failure at the edges, improving long-term insulation performance among many others. If you’re looking for high-quality warm edge spacers in India then you will want to check out M3 Extrusions. They offer a broad selection of high quality warm edge spacers engineered to increase the energy performance of industrial windows.

Frequently Asked Questions

What advantages do warm edge spacers provide compared to conventional metal spacers?

While metal spacers transfer heat into and through the window, making the glass cold which promotes heat loss, warm edge spacers use much less conductive materials, ultimately making the window warmer, and reducing heat loss at the edge of the glass.

How do warm edge spacers help prevent condensation in industrial windows?

Warm edge spacer systems keep the edge of the window warmer and therefore prevent moisture from settling as well as condensing. This avoids droplets of water forming on the glass, protects the window from that damaging moisture, and helps keep the interior dry and comfortable.

Can warm edge spacers be used in any kind of commercial window?

Warm edge spacers are suitable for dual and triple-glazed windows, the most common type of windows that are found in commercial buildings. The primary benefit of warm edge spacers is that they help to improve the thermal performance of the window, regardless of whether it has dual or triple glazing. Therefore they can be used in a variety of window styles.

Do warm edge spacers improve the durability of industrial windows?

Yes, certainly. The materials used in warm edge spacers do not corrode and are resistant to wear, to protect the area around the edges of the glass from damage. The lifespan of industrial windows is improved because the warm edge helps reduce the risk of seal failure and maintains insulation strength over time, even in severe environments.

How to select the right warm edge spacer for commercial windows?

Ultimately, your choice of warm edge spacer will vary based on the window type, climate, and your budget. Look for spacers that have low thermal conductivity, durability, and compatibility with double or triple glazing.