Every detail counts when it comes to refrigeration and cooling applications. From insulation to the materials used in constructing cooling units, it is very important to select components that can provide durability as well as efficiency. One such component that is gaining popularity in the cooling industry is PVC refrigeration profiles. These profiles offer a wide range of benefits that make them a great choice for your cooling needs.

What Are PVC Profiles?

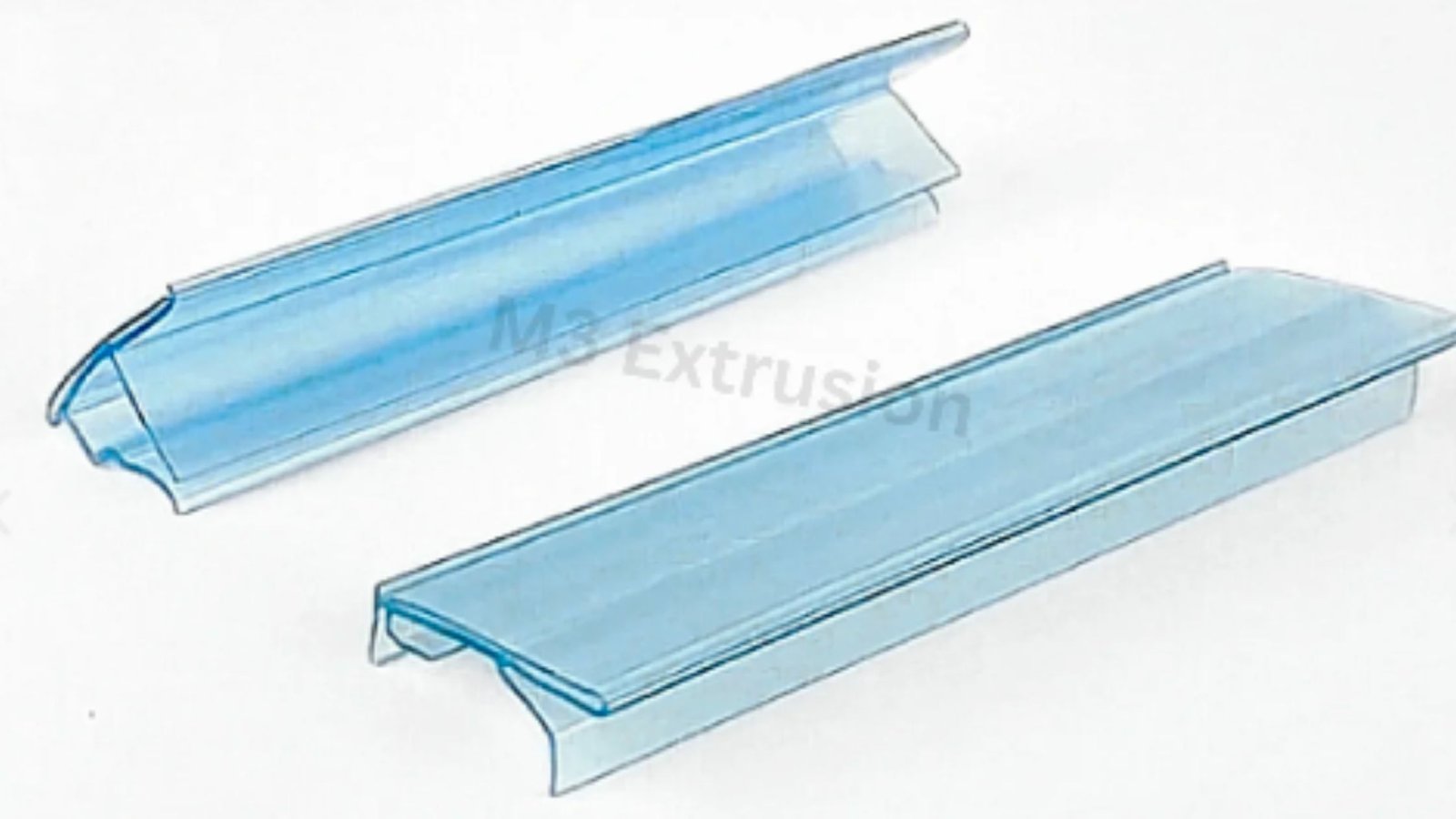

PVC (Polyvinyl Chloride) profiles are specifically designed plastic shapes for various applications, such as refrigeration systems. Profiles are moulded into shapes that serve a particular purpose, such as seals, frames, or insulation channels. They are made of plastic that is resistant to temperature fluctuations, moisture, and other environmental influences. In refrigeration systems, the profile plays an important role in keeping the cooling process intact.

Durability That Lasts

The main reason to opt for PVC profiles for your cooling needs is their unmatched durability. PVC is a strong material that resists wear and tear over time. Whether you’re dealing with low temperatures or high humidity, PVC profiles will stand up to the demands of refrigeration systems. Unlike metal components, which will corrode or rust with time, PVC will not get destroyed by moisture and temperature fluctuations, making it less expensive in the long run and reliable.

Efficient Insulation Properties

In refrigeration, insulation is crucial for efficiency in energy consumption. PVC profiles possess excellent insulation properties that contribute to reducing the amount of energy consumption. Since the profiles minimise cold air loss and prevent heat entry into the system, energy costs can be saved. Be it designing a freezer, cooler, or refrigerated display case, M3 Extrusion PVC refrigeration profiles ensure your system stays cool without wasting energy on anything that’s not needed.

Easy to Work With

Another huge advantage of PVC profiles is the ease with which they can be handled. The PVC material is light and pliable, and thus it’s easy to cut, shape, and install. Whether you’re building a small refrigeration unit or a large commercial cooling system, PVC profiles can easily be designed to suit specific needs. The flexibility in use reduces installation time and labor costs, making it convenient for any project.

Resistance to Harsh Environments

Refrigeration systems are usually exposed to harsh environments. Moisture, chemicals, and cold temperatures are inevitable, but PVC refrigeration profiles can handle these conditions without any problem. PVC is naturally resistant to water and chemicals, so it will not break down, crack, or degrade when exposed to these harsh elements. This resistance ensures that your cooling system remains functional and efficient for a long time, even in demanding environments like food storage or pharmaceutical cooling.

Hygienic and Easy to Clean

Hygiene is the first priority in industries such as food storage or pharmaceuticals. PVC profiles are non-porous, which means they do not absorb bacteria or other harmful pathogens. PVC is also convenient to clean and maintain, so your refrigeration systems will always meet strict hygiene standards. With a simple wipe-down, PVC profiles can be kept clean and sanitary, making them ideal for environments that require high cleanliness standards.

Cost-Effective Solution

Cost-effectiveness is a major factor to consider when determining the materials used in a cooling system. PVC profiles are definitely cheaper than their counterparts, be it metal or glass. Yet, they have all the advantages of durability, insulation, and resistance to external factors. The PVC profiles would thus be viable for small businesses as well as large commercial undertakings.

Versatility in Design

One of the most attractive features of M3 Extrusion PVC refrigeration profiles is that they allow for versatile design. These profiles can be easily moulded into a broad range of shapes and sizes with high degrees of customisation. Be it a specific frame size, a custom seal, or a specific insulation channel, PVC profiles can mould themselves to all the exact dimensions required. This flexibility will enable you to create systems of refrigeration that meet both your functional and aesthetic needs without compromise on performance.

Environmentally Friendly Option

In today’s world, environmental impact is a huge consideration. PVC profiles are much more sustainable compared to some of the other materials used in refrigeration systems. PVC is recyclable and has a relatively low environmental footprint if manufactured correctly. Choosing PVC for your refrigeration systems can help reduce waste and contribute to more eco-friendly practices within your business.

Why PVC Refrigeration Profiles are the Future

The demand in the cooling industry for more efficient and reliable refrigeration systems is a trend that continues to rise. The features of durability, low energy consumption, easy to fit, and affordable prices have made PVC profiles highly popular to be used in an environment that has such expectations in the future.

Whether you want to replace some worn-out parts in an already existing refrigeration unit or design a completely new system, PVC refrigeration profiles are the ideal solution. Versatile in nature, they will ensure that they meet the requirements of residential and commercial cooling systems with long-term benefits in terms of performance and cost efficiency.

Getting Together

It is important for cooling systems to have the correct material choices as they contribute to efficiency, durability, and other performance inputs. PVC refrigeration profiles are versatile, durable, and affordable solutions for various refrigeration applications. Their favourable insulation properties, durability, and easy maintenance qualify them as a perfect choice for any responsible member who needs constant refrigeration component performance.

If you’re looking to upgrade or design a new refrigeration unit, look into using M3 Extrusion PVC refrigeration profiles for a smarter, more efficient, and longer-lasting cooling solution.