LED strip lights are widely used for both residential and commercial lighting. They provide energy efficiency, flexibility, and modern aesthetics. However, these strips are delicate and can easily be damaged by dust, moisture, or accidental impact. Using a polycarbonate diffuser is one of the best ways to protect LED strips and ensure they last longer while maintaining optimal performance.

Why Do LED Strips Need Protection?

LED strips contain electronic components that can be affected by various factors:

- Dust and Debris: Accumulation of dust can settle on the LED surface, reducing brightness and affecting the efficiency of the LEDs over time. This can lead to uneven lighting and a dull appearance, diminishing the overall look of the space.

- Moisture Exposure: Water or humidity can easily cause short circuits and permanent damage to the LED strips. In high-humidity areas like kitchens or bathrooms, unprotected LEDs may stop functioning sooner than expected.

- Physical Impact: LED strips are delicate and can be damaged by accidental knocks or pressure, which may break the LED chips or loosen the circuit connections. This can lead to flickering lights or complete failure of sections within the strip.

- Heat Management: Continuous operation generates heat, and without proper protection, overheating can reduce the lifespan and lower the performance of the LEDs. Excess heat can lead to colour shifting and inconsistent brightness levels.

To overcome these issues, using a cover, particularly a polycarbonate diffuser, helps shield the LEDs while also enhancing the lighting effect.

What Is a Polycarbonate Diffuser?

A polycarbonate diffuser is a protective cover designed for LED lighting. It is made from polycarbonate, a durable and impact-resistant material that provides several advantages:

- High Strength: It can withstand significant impact better than glass or acrylic, making it an ideal choice for areas prone to accidental contact.

- UV Resistance: Prevents yellowing or degradation due to prolonged exposure to sunlight, ensuring the diffuser remains clear and effective over time.

- Light Diffusion: Softens and spreads the light evenly, reducing harsh glare and preventing visible LED hotspots, creating a smooth and visually appealing illumination.

- Heat Resistance: Can withstand high temperatures better than standard plastic covers, reducing the risk of warping or damage due to LED heat emissions.

Benefits of Using a Polycarbonate Diffuser for LED Strips

- Enhanced Light Distribution A polycarbonate diffuser ensures that light is evenly spread across the surface, eliminating harsh spots and creating a uniform, pleasant glow. This is particularly useful for ambient lighting in homes, offices, and commercial spaces.

- Protection from External Elements LED strips are exposed to dust, dirt, and accidental splashes of water. A properly fitted diffuser acts as a protective barrier, keeping contaminants away and ensuring the LEDs maintain their efficiency over time.

- Improved Aesthetics Open LED strips can sometimes look unrefined, with individual LEDs creating visible spots of light. A diffuser provides a sleek, professional finish by softening the light, making the installation blend seamlessly with modern interiors.

- Extended Lifespan of LEDs Shielding the LEDs from dust, moisture, and accidental contact helps maintain their brightness and prevents premature failure. This means fewer replacements and long-term cost savings for businesses and homeowners.

- Energy Efficiency A well-designed diffuser maximises the efficiency of the LED strips by ensuring that light is distributed optimally, reducing unnecessary brightness loss and lowering energy consumption.

- Customisation Options With various finishes available, including frosted and clear diffusers, lighting installations can be customised to match different design preferences. Frosted diffusers provide softer illumination, while clear options retain maximum brightness.

Choosing the Right Polycarbonate Diffuser for Your LEDs

When selecting a polycarbonate cover, consider the following factors:

- Transparency Level: Choose between clear, frosted, or opal diffusers depending on the desired level of light diffusion. Frosted diffusers reduce glare, while clear options provide direct, high-brightness output.

- Size and Shape: Ensure the diffuser fits your LED profile or mounting channel properly to avoid light leakage or installation difficulties.

- UV Protection: If using outdoors or in areas exposed to direct sunlight, opt for a UV-resistant version to prevent discoloration and material degradation.

- Heat Resistance: LEDs generate heat, so it’s essential to use a heat-resistant diffuser that won’t warp or deteriorate over time.

- Compatibility with Mounting Channels: A secure, well-fitted diffuser ensures stability and even light distribution, improving both function and aesthetics.

How to Install a Polycarbonate Diffuser on LED Strips

Installing a polycarbonate diffuser is a straightforward process that requires minimal tools. Follow these steps for a secure fit:

- Measure the LED strip length and cut the diffuser to match, ensuring precise coverage without gaps.

- Attach the LED strips securely to an aluminium channel or mounting surface, ensuring they are evenly spaced for uniform lighting.

- Slide or snap the diffuser onto the channel, making sure it locks into place for a stable and professional finish.

- Test the lighting before finalising installation to check for even distribution, brightness level, and any necessary adjustments.

- Seal the ends properly using end caps or silicone seals if required, preventing dust or moisture from entering the diffuser and affecting the LEDs.

Common Mistakes to Avoid When Using LED Diffusers

- Choosing the Wrong Transparency: Using a diffuser that is too opaque can block too much light, reducing the LED’s efficiency, while a completely clear cover may not soften the light effectively.

- Ignoring Heat Management: Always pair diffusers with aluminium channels to help dissipate heat and maintain consistent LED performance over time.

- Improper Installation: Loose or poorly fitted diffusers may fall off or fail to protect the LEDs effectively, reducing their longevity.

- Using Incompatible Materials: Not all plastics are suitable for LED applications. Ensure the diffuser is made from high-quality polycarbonate designed for LED lighting to prevent yellowing and brittleness.

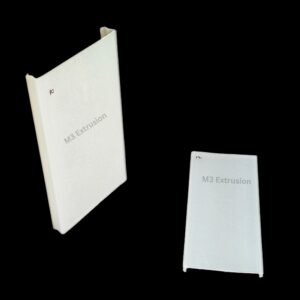

Why Choose M3 Extrusion for Your LED Diffuser Needs?

At M3 Extrusion, we manufacture high-quality polycarbonate diffusers designed to improve LED performance and longevity. Our diffusers are crafted to provide protection against environmental elements while ensuring an optimal lighting experience. Whether you need customised LED covers for commercial projects or residential lighting, we offer solutions tailored to industry requirements.

By choosing M3 Extrusion, you benefit from:

- Customised designs that perfectly fit your LED profiles, ensuring seamless integration.

- High-quality materials that provide durability, impact resistance, and long-term performance.

- Reliable UV and heat resistance for both indoor and outdoor applications, preventing yellowing or damage over time.

- Expert guidance to help you select the ideal diffuser based on your specific lighting needs.

Conclusion

Using a polycarbonate diffuser is an effective way to protect LED strip lights while enhancing their light quality and longevity. A well-designed diffuser not only safeguards LEDs from dust, moisture, and physical damage but also improves aesthetics and energy efficiency. Whether for home interiors, offices, or large commercial spaces, adding a durable cover ensures your LEDs remain bright and damage-free for years to come.