Rigid PVC profiles are widely used across multiple industries due to their stable performance, low maintenance needs, and ease of installation. Common applications include construction systems, electrical setups, HVAC ducts, food processing areas, pharmaceutical facilities, packaging lines, automotive units, and general manufacturing floors.

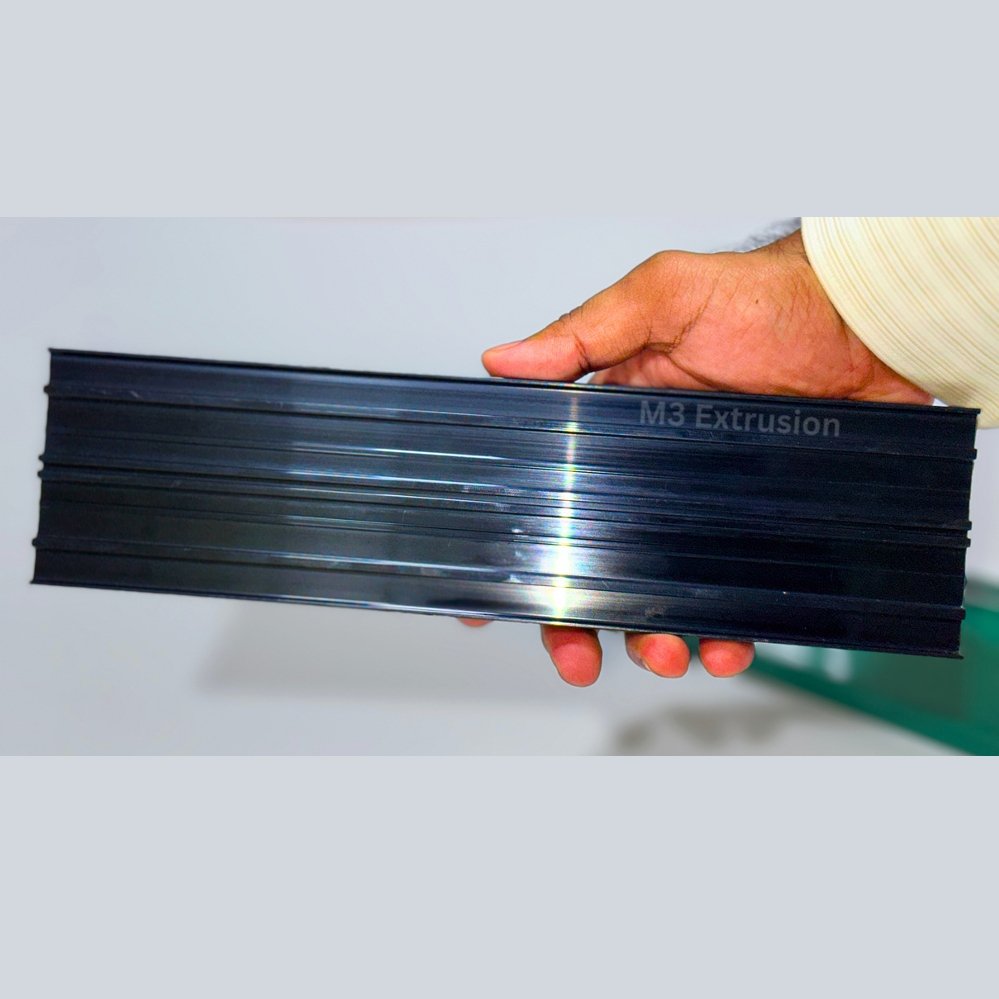

These profiles are produced through extrusion using PVC resin blended with stabilisers, impact modifiers, fillers, and colour additives as required. The result is a long, shaped component that maintains dimensional accuracy and structural consistency over extended periods of use.

Rigid PVC profiles in India are valued for their ability to retain shape under daily operational stress. They remain stable when exposed to temperature changes, moisture, dust, and routine cleaning, making them suitable for demanding industrial environments.

Why Industries Choose Rigid PVC Profiles

Industries prefer rigid PVC profiles because they offer a balance of strength, low weight, and cost efficiency. Their consistent shape simplifies design planning and reduces installation complexity.

These profiles are easy to cut, drill, and assemble using standard tools. Engineers and maintenance teams benefit from faster installation, fewer adjustments, and reduced downtime during upgrades or repairs.

Because rigid PVC profiles require minimal upkeep and perform reliably over time, they help facilities maintain smooth operations without frequent inspections or part replacement.

Key Properties of Rigid PVC Profiles

Rigid PVC profiles provide several characteristics that make them suitable for industrial use.

Stable shape and dimensional accuracy

Resistance to moisture, dust, and common chemicals

Lightweight yet structurally reliable

Easy machining and installation

Long service life with low maintenance needs

These features allow rigid PVC profiles to integrate smoothly into both new installations and existing systems.

7 Industrial Applications of Rigid PVC Profiles

Rigid PVC profiles are used in a wide range of industrial applications where consistency, durability, and adaptability are required.

Framing Systems

Rigid PVC profiles are commonly used to manufacture window frames, door frames, and light structural supports. They cut and join cleanly, allowing accurate fitting for both standard and custom openings.

Their ability to hold square after installation reduces rework and speeds up project completion. The low weight also makes handling easier and lowers stress on support structures.

Wall and Ceiling Panelling

For industrial wall and ceiling panelling, rigid PVC profiles provide smooth, wipeable surfaces that simplify cleaning and routine maintenance.

They are produced in long lengths, reducing joints and creating a uniform finish. Damaged sections can be replaced easily without disturbing surrounding panels, helping minimise downtime.

Cable Management Systems

Rigid PVC profiles are widely used for cable trays, channels, and trunking. They help keep wiring organised, protected, and accessible across factory floors and service areas.

Their smooth interior surface reduces cable snagging, while clean cutting allows installers to adjust lengths and bends on site with minimal waste.

Covers and Access Panels

These profiles are well suited for removable covers and access panels on machines and control boxes. They machine cleanly, allowing precise fitting and secure fastening.

Lightweight panels are easy to remove for inspections, repairs, or servicing, reducing maintenance time and improving operational efficiency.

Guide Rails and Conveyor Channels

Rigid PVC profiles provide smooth, low-friction surfaces ideal for guide rails and conveyor systems. They help maintain consistent product movement with minimal drag.

Their low weight reduces load on frames and bearings, while resistance to wear allows longer service intervals between replacements.

Pipe Supports and Saddles

Rigid PVC profiles are used to form pipe supports, spacers, and saddles. They hold pipes in correct alignment and reduce wear on pipe surfaces.

The material resists rust and common industrial chemicals, extending service life. Custom shapes allow fitting in tight or complex layouts.

Shelving and Storage Components

Rigid PVC profiles are used in shelving systems, bin dividers, brackets, and mounting rails. They cut and drill easily, allowing on-site sizing with standard tools.

Their corrosion resistance and smooth surfaces make cleaning easy, while long lengths reduce joints and improve overall finish.

Benefits of Using Rigid PVC Profiles in Industrial Projects

Rigid PVC profiles offer a practical and cost-effective solution for many industrial needs.

Faster installation with standard tools

Reduced handling time due to low weight

Long service life with minimal maintenance

Compatibility with existing systems

Custom extrusion options for specific site requirements

These advantages help engineers and facility managers maintain organised, efficient, and reliable operations.

Choosing the Right Rigid PVC Profile Supplier

Selecting a reliable manufacturer ensures consistent quality, accurate dimensions, and dependable performance. Custom extrusion capabilities allow profiles to match exact application needs without major system changes.

If you are looking for custom rigid PVC profiles for industrial projects, M3 Extrusion specialises in durable, high-performance solutions tailored to multiple industries.

Frequently Asked Questions

How are rigid PVC profiles made?

They are produced through extrusion, where PVC resin is blended with additives, heated, and pushed through a shaped die. The profile cools into a stable section and is cut to length.

Why do industries choose rigid PVC profiles over metal parts?

Rigid PVC profiles are lightweight, corrosion-resistant, easy to machine, and require less maintenance compared to metal components.

Are rigid PVC profiles suitable for harsh industrial environments?

Yes. They perform well in environments with moisture, dust, and routine wear, and resist rust and many common chemicals.

Can rigid PVC profiles be customised for specific applications?

Yes. They can be extruded in various shapes, lengths, and colours to meet exact project requirements.

Summary

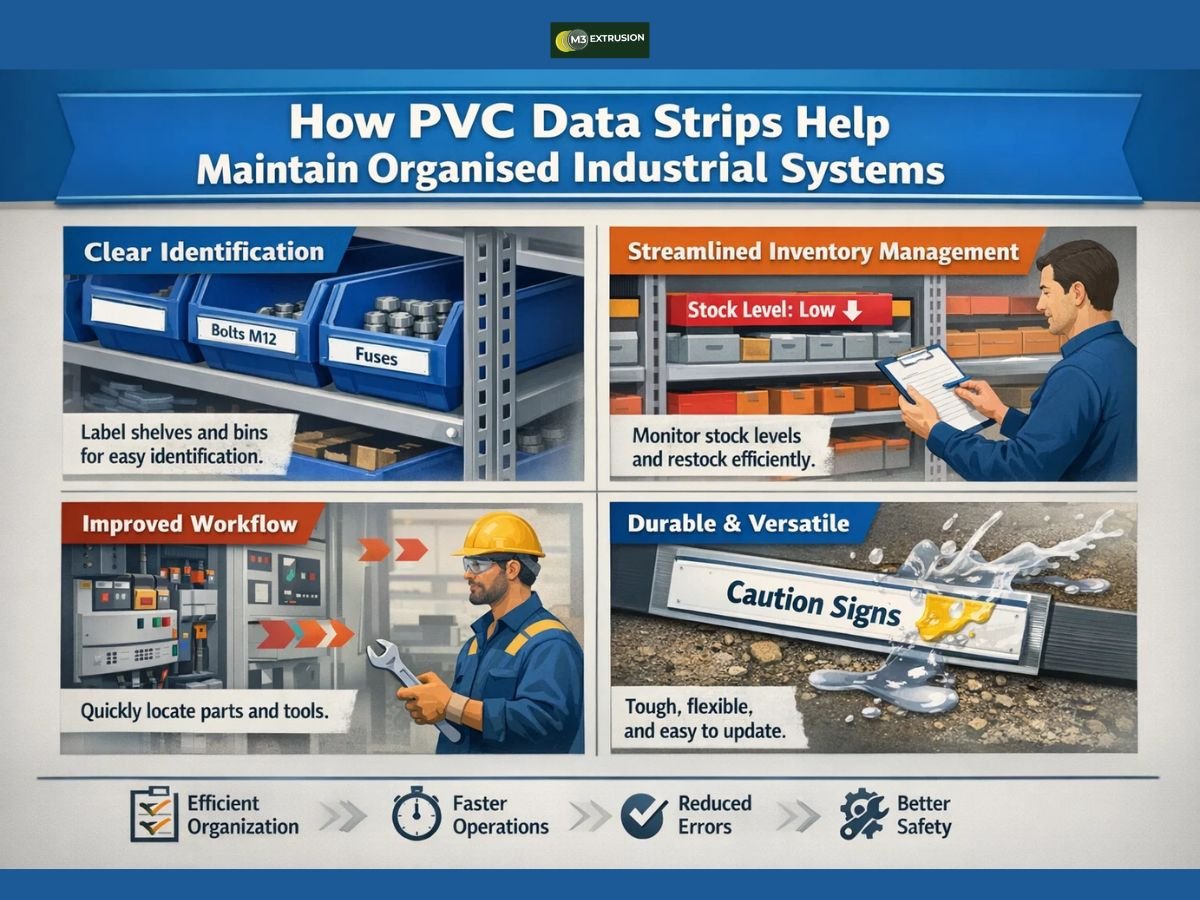

Rigid PVC profiles are a dependable choice for modern industrial applications. Their stable shape, low maintenance needs, and ease of installation make them suitable for framing, panelling, cable management, covers, guide rails, pipe supports, and storage systems.

With long service life and wide adaptability, rigid PVC profiles help industrial facilities stay organised, efficient, and cost-effective over time.