Installing a white LED diffuser may seem like a simple task, but small mistakes during fitting can lead to poor lighting results, uneven brightness, or even damage to the fixture. In commercial settings where presentation and comfort matter, avoiding these mistakes is key.

Whether you’re fitting lights in a showroom, office, or public space, understanding the right way to install a white LED diffuser in India helps ensure better lighting performance, energy efficiency, and product life.

Using the Wrong Diffuser for the Application

Not all diffusers are the same. Choosing a diffuser without checking material type, thickness, or light transmission often leads to poor light quality. For example, a diffuser that is too thick or opaque can dim the light too much, while a clear cover may cause glare.What to do instead:

Select a white or opal diffuser that matches your fixture design and lighting goals. For soft lighting, use a frosted finish with moderate light transmission.

Poor Alignment with the LED Strip

If the diffuser is not properly aligned with the LED strip inside the housing, it creates uneven lighting. Dark spots or visible LED dots may appear, especially in long-profile lights.What to do instead:

Ensure the LED strip is centred and flat inside the profile. Use diffusers that clip or slide in tightly, without gaps or bending.

Using Low-Quality Material

Some installers use basic plastic diffusers that discolour, crack, or turn brittle over time. In Indian conditions where heat, dust, and humidity vary by region, poor material choice leads to faster wear.What to do instead:

Choose materials like polycarbonate (PC) or PMMA for long-lasting durability. These materials resist heat, impact, and UV exposure better than standard plastics.

Cutting Without Proper Tools

Cutting the diffuser manually or with the wrong tools can cause rough edges, cracks, or uneven lengths. This affects both appearance and fit.What to do instead:

Use proper cutting tools or request pre-cut profiles from your supplier for a clean, finished look.

Ignoring Fit and Grip

Loose-fitting diffusers can fall off or allow dust inside the fixture. On the other hand, overly tight diffusers may crack during fitting.What to do instead:

Always check profile and diffuser compatibility before installation. Custom profiles offer the best grip without forcing.

Forgetting to Clean the Surface

Installing diffusers without cleaning the surface can trap dust or debris inside. Once sealed, this dust becomes visible when the light is on.What to do instead:

Clean the housing and diffuser thoroughly before final assembly to ensure a clean light output.

Overlooking the Light Transmission Value

Some projects require diffused light with minimal brightness loss, while others need a more solid, soft glow. Choosing the wrong transmission level affects the lighting effect.What to do instead:

Understand the project’s lighting needs and match the diffuser’s opacity or finish accordingly.

Why It Matters in Commercial Projects

Improper installation doesn’t just affect lighting—it reflects poorly on the entire fit-out. In retail, hospitality, and public infrastructure projects, lighting quality is linked to brand perception and user comfort.

To make sure every fixture performs as expected, correct installation of the diffuser is just as important as the LED strip itself.

Know What a Diffuser Does

If you missed our detailed guide on how diffusers work and their impact on lighting, read:

👉 How a White LED Diffuser Helps Create Soft, Uniform Lighting in Commercial Spaces

This helps you understand the role of materials, design, and light spread in every fitting.

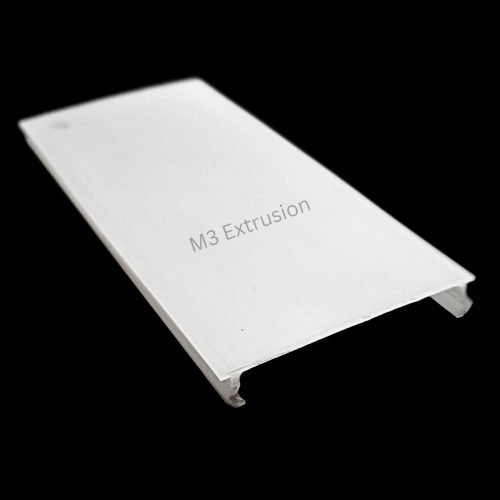

Custom White LED Diffuser Profiles for India’s Projects

At M3 Extrusion, we support lighting manufacturers, contractors, and system designers with high-performance white LED diffuser profiles in India. Our products are:

- Made using durable PC or PMMA

- Suitable for Indian temperature and humidity ranges

- Customisable to match your lighting system

- Supplied in bulk with consistent surface quality

If your project needs a reliable LED cover with smooth light output and a strong finish, we’re here to help.

Visit M3 Extrusion to get a quote or speak with our team about profile matching and custom designs.

Frequently Asked Questions (FAQ)

Q1. Can I replace an old diffuser with a custom one?

Yes. With custom extrusion, you can match the dimensions of older models and get a better fit and performance.

Q2. How do I prevent light dots from showing through the diffuser?

Use higher-density diffusers with a frosted finish and ensure the LED strip has even spacing.

Q3. What causes a diffuser to turn yellow over time?

This usually happens with low-grade plastics. Materials like UV-stabilised polycarbonate avoid this issue.

Q4. Is it safe to cut the diffuser on-site?

Yes, but it must be done with proper tools to avoid damage or cracking.

Q5. Are your diffusers suitable for both indoor and semi-outdoor use?

Yes. We offer profiles in materials that perform well in both conditions, based on your project needs.