There’s no denying that PVC profiles play a key role in industrial and building projects, supporting everything from structural panels and partitions to doors, windows and custom components. Not only do they offer strength and durability under heavy use, but they also resist water, chemicals, insects and extreme temperatures, reducing maintenance and replacement costs.

Unlike wood, which can warp or decay or metal, which may corrode and need coatings, PVC profiles provide consistent performance over time.

Available in hollow, solid, foamed, and co-extruded forms, PVC profiles meet a wide range of industrial needs, from structural supports to functional and decorative finishes, and are commonly used in door frames, partitions, and as a window PVC profile in India. This versatility makes them a cost-effective as well as reliable choice for demanding industrial projects.

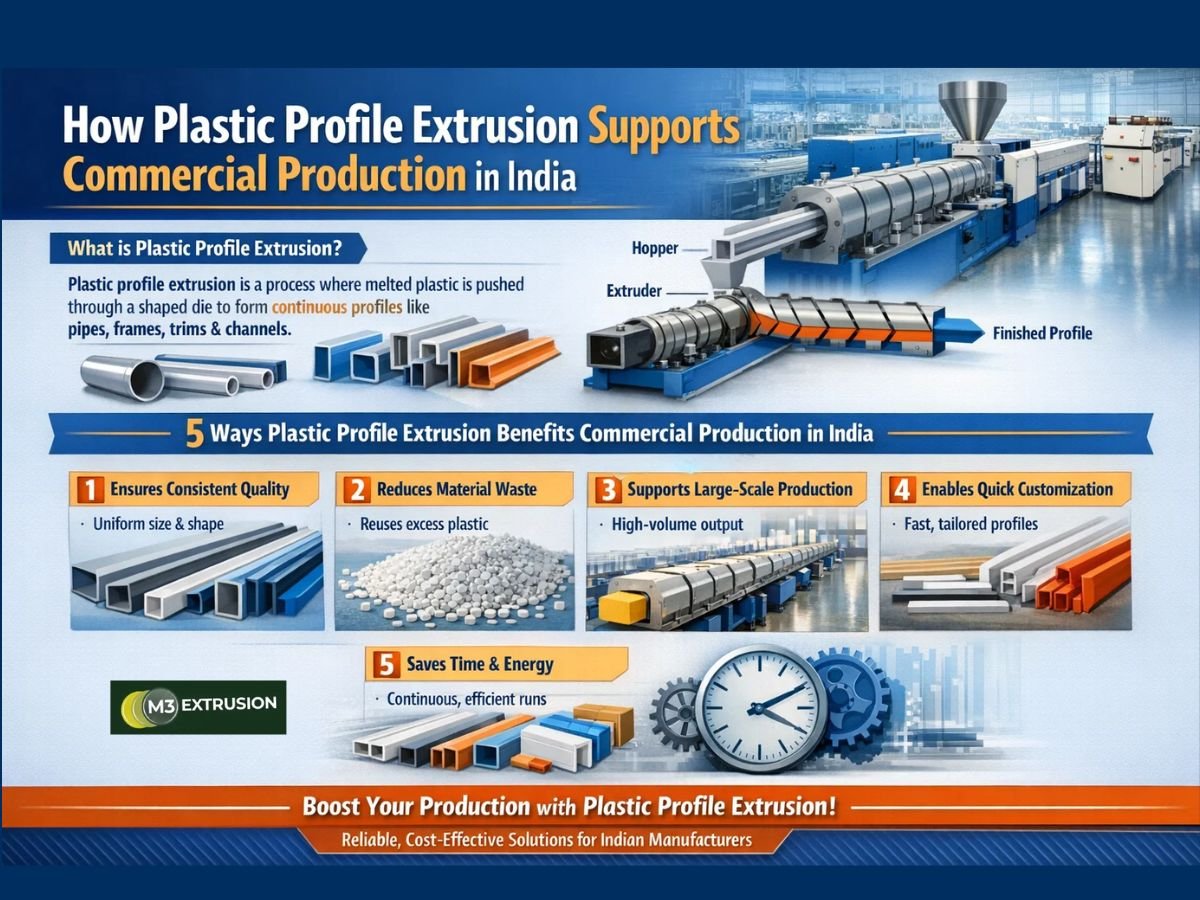

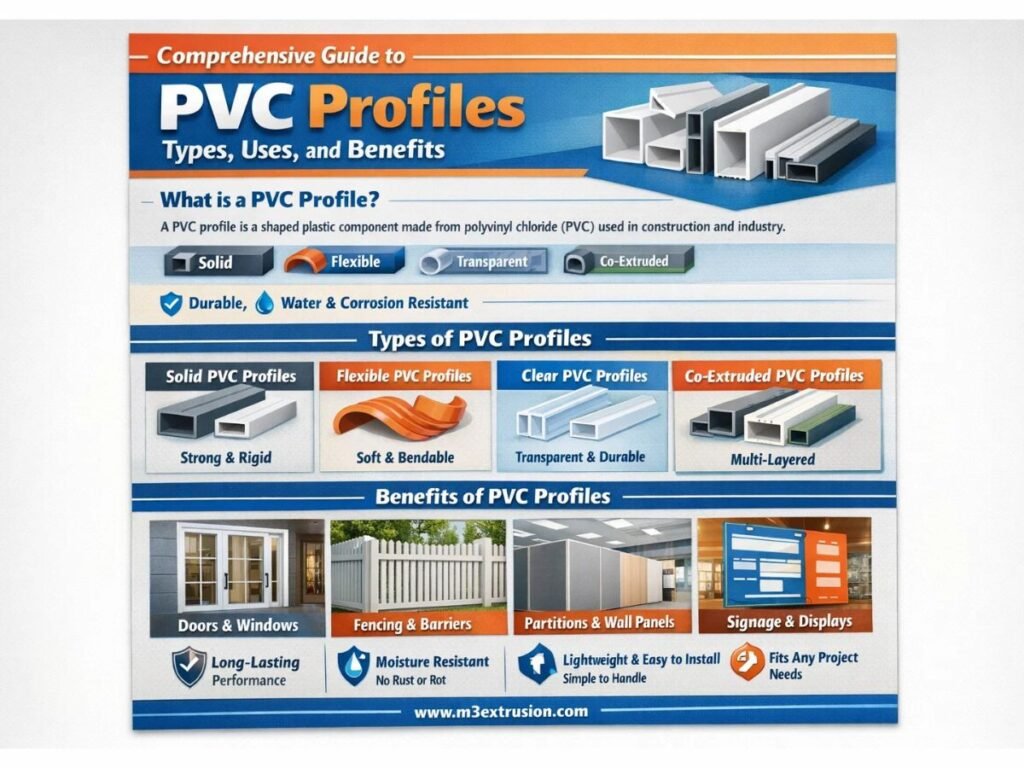

What is a PVC profile?

A PVC profile is a shaped piece of plastic made from polyvinyl chloride (PVC). It comes in various forms, such as hollow, solid, foamed, or co-extruded. These profiles are used to create strong and durable components for industrial and construction projects. Common applications include doors, windows, partitions, panels, fencing and signage.

PVC profiles are lightweight, easy to cut and install and resistant to water, chemicals, insects and extreme temperatures. Unlike wood or metal, they do not warp, rust or require frequent maintenance. Their versatility and consistent quality make them ideal for both structural and decorative purposes in industrial production and building projects.

Types of PVC Profiles

PVC profiles are available in different forms, each designed for specific industrial and construction needs. They vary in strength, weight, insulation and flexibility, making them suitable for both structural as well as decorative applications.

Here are the different types of PVC profiles:

Solid PVC Profiles

Designed for heavy-duty structural applications that demand maximum strength and rigidity, solid PVC profiles are dense and durable. They are commonly used in door and window frames, partitions, and load-bearing components.

Their rigidity ensures long-lasting performance, stability and resistance to wear in industrial and construction projects.

Soft/Flexible PVC Profiles

Soft and flexible, these PVC profiles provide cushioning, sealing and impact resistance. They are commonly used in gaskets, protective trims, edge guards, and flexible partitions.

Their bendable nature ensures long-lasting performance and reliable protection in industrial and construction applications.

Clear/Transparent PVC Profiles

As the name suggests, these profiles are transparent, combining visibility with strength and durability. They are commonly used for protective covers, display panels and light-transmitting components, offering reliable performance and resistance to impact, chemicals and weather in industrial and construction applications.

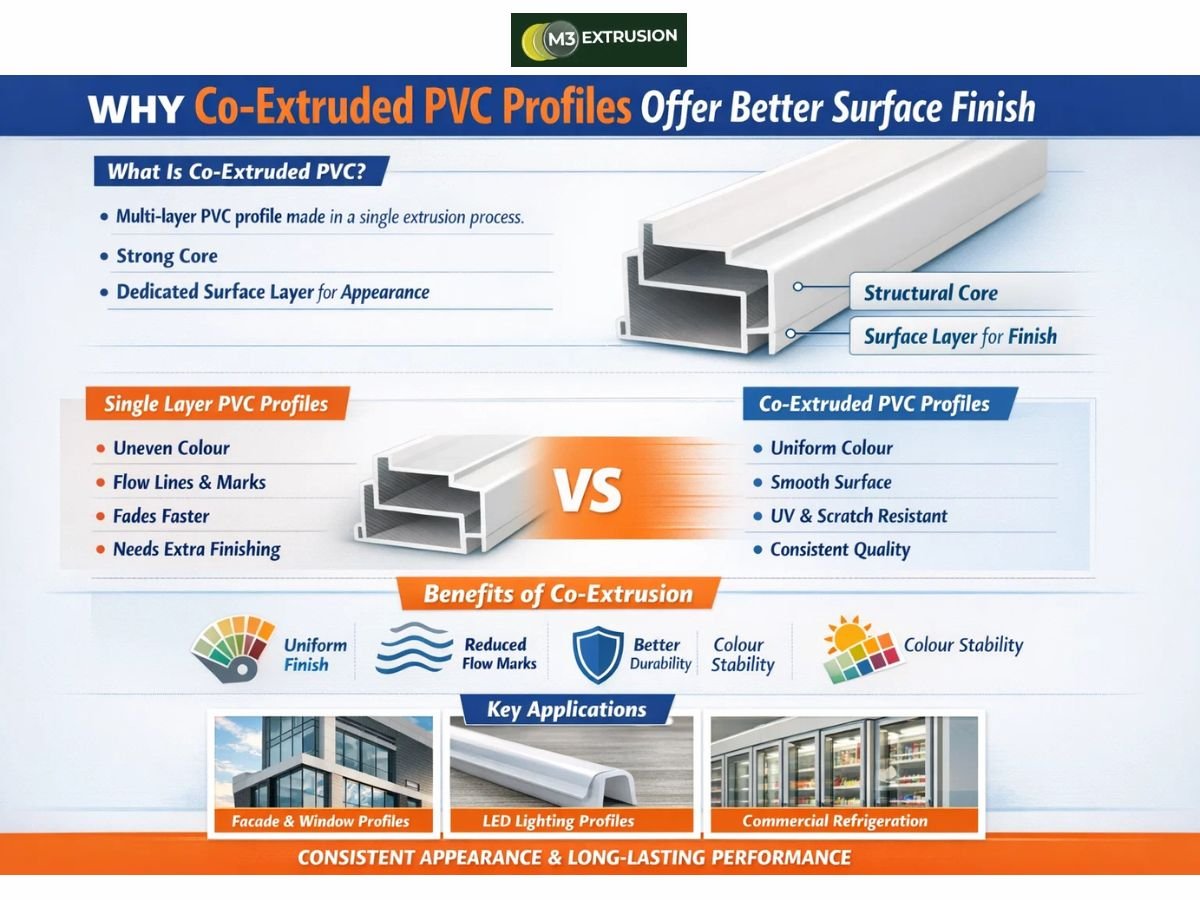

Co-Extruded PVC Profiles

Made using two or more PVC layers in a single extrusion process, co-extruded PVC profiles combine multiple properties in one product. A rigid layer provides strength and stability, while a softer or finished layer improves sealing, surface finish or weather resistance for demanding industrial and building applications.

Common Uses of PVC Profiles

Due to their strength, durability, and low maintenance, PVC profiles are widely used across industrial and construction projects. They perform well in environments exposed to moisture, chemicals and frequent use.

Their stable structure and resistance to wear make them suitable for both indoor as well as outdoor applications. PVC profiles are commonly used in doors, windows, partitions, panels, fencing and signage.

They also support protective trims, sealing components, and custom industrial parts. Their lightweight nature simplifies handling and installation while maintaining reliable performance. This combination of practicality and versatility allows PVC profiles to meet varied functional as well as structural needs across industries.

Listed below are some of the common uses of PVC profiles:

Doors and Window Frames

One of the most common uses of PVC profiles is in forming rigid frames for doors and windows in industrial and commercial buildings. These profiles provide consistent strength, resist moisture and corrosion, and maintain shape under frequent use.

Their low maintenance and weather resistance make them suitable for factories, offices and facilities that require durable, long-lasting installations.

Fencing and Barriers

Apart from being used for doors and window frames, PVC profiles are also used for fencing and barrier systems in industrial and commercial spaces. They provide strength, weather resistance, and long-term stability in outdoor and high-exposure areas.

Their resistance to moisture, corrosion and impact makes them suitable for boundary fencing, safety barriers and controlled-access zones.

Partitions and Wall Panels

PVC profiles are widely used to create durable partitions and wall panels in industrial and commercial facilities, providing strong, low-maintenance separation for offices, factories and warehouses. Their lightweight yet durable structure provides effective separation while resisting moisture, wear and impact.

They can be installed easily and require minimal upkeep, providing factories, offices, warehouses, and other industrial facilities with durable, long-lasting partitions that maintain performance and appearance over time.

Signage and Display Systems

From industrial signboards to commercial display panels, PVC profiles provide strong and durable frames for signage and display systems. They resist impact, moisture and corrosion while maintaining alignment and stability.

Their long-lasting performance and low maintenance make them ideal for both indoor and outdoor use in factories, offices, and public spaces.

Protective Trims and Edge Guards

PVC profiles form protective trims and edge guards for machinery, walls, corners and high-traffic surfaces in industrial and commercial facilities. They absorb impact, prevent damage, and reduce wear, while resisting moisture, chemicals, and corrosion.

Lightweight yet durable, these profiles require minimal maintenance and provide long-lasting protection, helping maintain the integrity and appearance of equipment, walls, and other critical surfaces.

Benefits of PVC Profiles

In today’s industrial and construction projects, PVC profiles are a preferred choice for structural components, partitions, doors, windows, fencing, and signage due to their strength, durability and low maintenance. They perform reliably in environments exposed to moisture, chemicals, and frequent wear, making them suitable for both indoor and outdoor applications.

Their lightweight yet sturdy design simplifies handling, transportation and installation while maintaining long-term stability. PVC profiles also offer excellent resistance to corrosion, impact, and deformation, reducing replacement costs and downtime.

With versatile shapes, finishes, and customizable designs, they provide functional and aesthetic solutions for industrial spaces, helping facilities maintain efficiency, safety and a professional appearance over time.

Here are some of the major benefits of PVC profiles:

Durability and Strength

Unlike wood or metal alternatives that can warp, crack or corrode over time, PVC profiles maintain their shape and performance under heavy use, moisture and environmental stress. Their rigid construction ensures that frames, partitions, and panels remain stable even in demanding industrial and commercial settings.

- Supports heavy loads: PVC profiles have a rigid structure that can handle structural and functional loads without bending or breaking.

- Maintains long-term stability: They stay strong and stable over years of use, even in industrial and outdoor environments.

- Resists impact: PVC profiles absorb shocks and impacts, protecting frames, partitions, and other components from damage.

By offering durability and strength, PVC profiles reduce replacement needs, lower maintenance costs and ensure reliable, long-lasting performance across industrial and construction projects.

Moisture and Corrosion Resistance

In addition to being strong and long-lasting, PVC profiles resist water, chemicals, and rust, ensuring reliable performance in industrial and construction settings. Their ability to withstand harsh environmental conditions allows them to maintain structural integrity and appearance over time, even in exposed or high-humidity areas.

- Prevents water damage: PVC profiles do not warp, swell or rot when exposed to humidity, rain or condensation, keeping doors, windows, panels and partitions stable and functional.

- Resists chemicals: They maintain performance when exposed to industrial fluids, cleaning agents, oils and other chemicals, preventing degradation as well as ensuring consistent reliability.

- Long-lasting protection: PVC profiles retain their strength, shape and finish over years of use, reducing repair needs and extending service life in demanding industrial environments.

This resistance to moisture and corrosion ensures PVC profiles deliver long-lasting, low-maintenance performance, keeping industrial installations protected and reducing the need for repairs or replacements over time.

Lightweight and Easy to Handle

PVC profiles are naturally lightweight, making them easier to transport, handle and install in industrial and construction projects. They can be moved as well as installed quickly, helping projects stay on schedule.

- Simplifies transportation: PVC profiles can be moved and stored easily without requiring heavy machinery, reducing logistical challenges.

- Maintains structural integrity: Despite being lightweight, PVC profiles retain strength and stability, supporting long-lasting performance in demanding industrial environments.

- Eases installation: Because of their lightweight design, PVC profiles make it easier and safer to install doors, windows, partitions, panels and other components.

This combination of lightness and strength ensures quicker project execution, lower labor costs and reliable performance over time.

Versatility and Customization

PVC profiles can be produced in a wide range of shapes, sizes as well as finishes, allowing them to meet diverse industrial and construction requirements. Their adaptable design makes them suitable for structural components, partitions, doors, windows, fencing, signage and protective systems.

- Allows design flexibility: Profiles can be cut, shaped, or combined to fit unique spaces, specifications, or operational needs.

- Accommodates finishes and coatings: They come in a variety of textures, colors and protective coatings, which enhance both their appearance and durability, improving resistance to wear and ensuring long-lasting performance in industrial and commercial applications.

- Integrates with different systems: PVC profiles can be easily combined with metal, glass or other construction materials, allowing seamless integration into complex industrial structures as well as multi-material projects.

This versatility ensures PVC profiles provide customized, practical solutions for a wide range of industrial installations.

PVC profiles have become a key material in industrial as well as construction projects due to their strength, durability, versatility and low maintenance. From doors and windows to partitions, fencing, signage and protective systems, they deliver reliable performance in both indoor and outdoor environments.

By choosing PVC profiles, industries can ensure safer, more efficient and durable structures while reducing maintenance and operational costs over time. Are you looking for high-quality PVC profiles for your industrial or construction projects? M3 Extrusion offers a wide range of durable, versatile and customizable PVC profiles to meet all your structural, decorative, and protective needs.

Frequently Asked Questions

What are PVC profiles used for in industrial projects?

PVC profiles are used for doors, windows, partitions, panels, fencing, signage and custom components. They provide strength, durability and low maintenance, making them suitable for structural and decorative purposes in industrial and construction applications.

How durable are PVC profiles?

PVC profiles are highly durable. They resist water, chemicals, insects, and extreme temperatures. Unlike wood or metal, they do not warp, rust or decay, making them ideal for long-lasting industrial and construction applications.

Are PVC profiles cost-effective for industrial projects?

PVC profiles are lightweight, strong and easy to maintain, which keeps installation and upkeep costs low. They can replace wood or metal in many applications, making them a practical as well as cost-effective choice for industrial and construction projects.

Can PVC profiles be customized for specific industrial needs?

Yes. PVC profiles can be cut, shaped, and colored to meet specific requirements. They can be designed for unique dimensions, decorative finishes or functional purposes, making them adaptable for industrial and construction projects.

Are PVC profiles environmentally friendly?

PVC profiles are recyclable and have a long service life, reducing waste over time. Their durability and low maintenance also lower the need for frequent replacements, making them a sustainable choice for industrial and construction projects.

Check related articles for more insights:

- How to Improve Weather Resistance with Durable PVC Sealing Solutions

- How to Improve Weather Resistance with Durable PVC Sealing Solutions

- Why uPVC Window Seals Matter for Long-Lasting Performance in Indian Homes