Modern industries demand materials that are both lightweight and durable. From construction and automotive to electrical fittings and packaging, businesses want solutions that reduce weight without losing strength. This balance is where custom extruded plastic in India has become an effective option for many manufacturers.

By shaping plastics through extrusion, companies can achieve designs that meet specific needs while maintaining long-term performance. These profiles not only save on material and production costs but also help in bulk supply, making them a preferred choice in B2B applications.

Why Lightweight and Strong Materials Matter

Every industry today faces the challenge of designing products that are efficient, cost-effective, and easy to transport. Heavy materials may provide strength but often increase costs and energy use. On the other hand, very light materials can lack durability.

Custom extruded plastics solve this issue by providing:

- Strength with reduced weight, ensuring products are easier to handle.

- Flexibility in design, allowing for precise shapes.

- Lower production costs, especially when manufactured in bulk.

This combination makes them suitable for applications like sealing profiles, window frames, protective covers, and packaging solutions.

The Role of Custom Extrusion in Product Design

Extrusion technology gives manufacturers the ability to create plastics that are highly adaptable. Unlike generic materials, custom extruded plastic can be shaped to meet specific technical and design requirements.

Key advantages include:

- Accurate dimensions for components that require tight fitting.

- Consistent quality across large orders.

- Adaptability, as the same process can work with PVC, ABS, PP, and other polymers.

For example, a construction company might need a lightweight spacer that can handle temperature changes, while an electronics supplier may require protective sleeves. Extrusion allows both to get exactly what they need without compromise.

Benefits of Using Custom Extruded Plastic

1. Reduced Manufacturing Costs

Producing parts with extrusion often requires less raw material compared to traditional methods. This results in lower costs per unit, especially in bulk production.

2. Better Performance in Harsh Conditions

Many extruded profiles are resistant to moisture, chemicals, and UV exposure. This durability means fewer replacements, reducing long-term costs.

3. Design Flexibility

Whether it’s a unique colour, a specific thickness, or an unusual shape, extrusion supports a wide range of design requirements.

4. Large-Scale Supply

Because extrusion supports continuous production, it is ideal for businesses needing thousands of profiles in a short time.

Applications Across Industries

Custom extruded plastics are used across multiple sectors due to their adaptability.

- Construction: Window seals, spacers, weatherproof strips.

- Automotive: Lightweight trims, protective covers, cable channels.

- Electrical: Insulation tubes, wire protectors, switchboard parts.

- Furniture: Edge bands, flexible corners, protective mouldings.

- Packaging: Impact-resistant profiles for safe storage and transport.

This wide application range shows why so many businesses are turning to extrusion-based solutions.

Bulk Orders and Business Supply

One of the biggest advantages of extruded plastic is how well it fits into bulk supply models. Manufacturers and distributors can order large quantities while still maintaining product consistency.

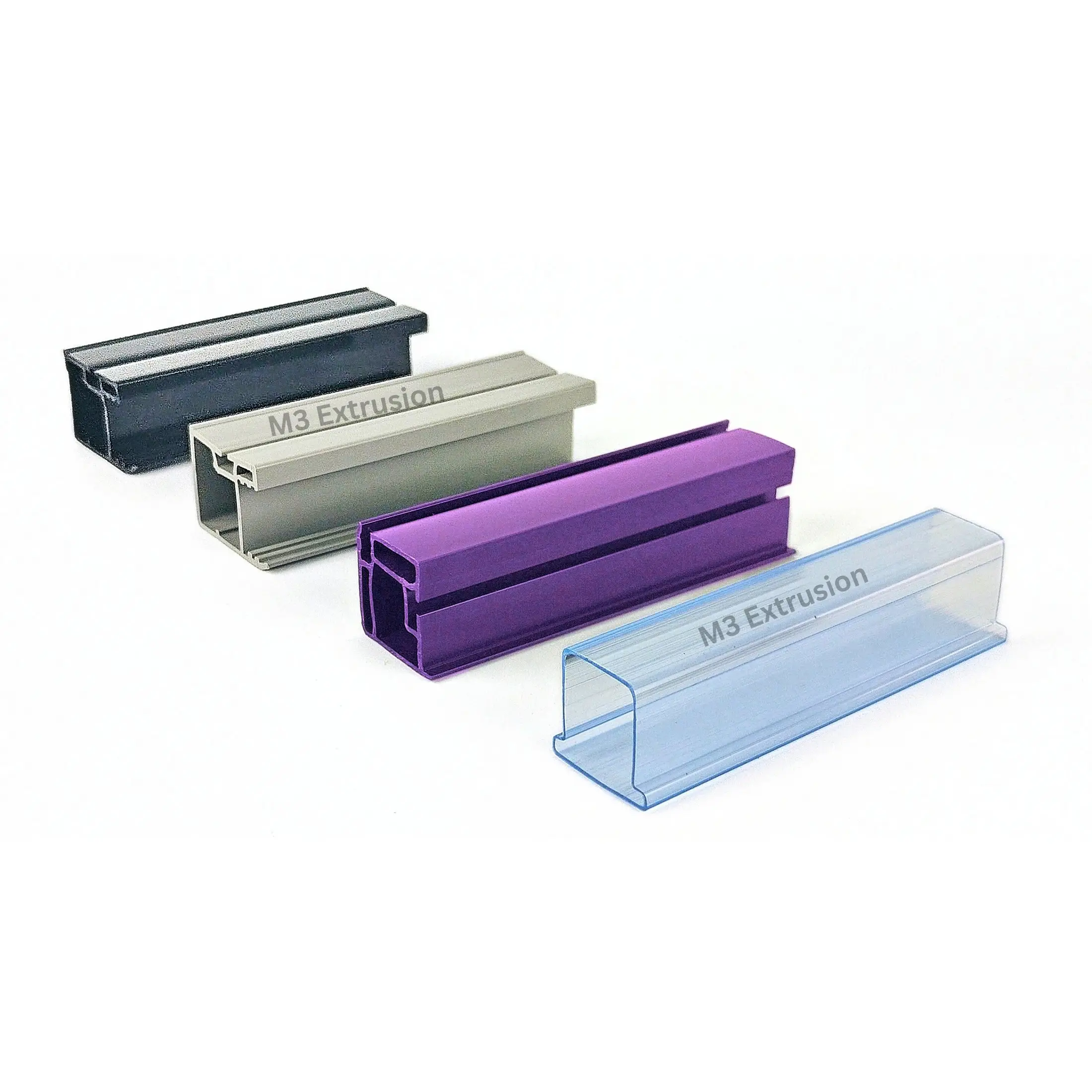

For example, M3 Extrusion provides industries with the ability to request bulk orders based on specific profiles. This means businesses can reduce downtime, improve efficiency, and avoid frequent reordering.

When talking about reducing waste and cost overruns, industries in the USA and other markets have already shown how extruded plastic can support these goals. A similar approach is now widely used in India, helping companies cut unnecessary costs while improving output.

How It Supports Sustainability Goals

Sustainability is another area where extruded plastic plays a role. Many manufacturers today face strict environmental standards, and extrusion helps by:

- Using only the required material, reducing waste.

- Allowing recycled plastic to be reprocessed.

- Creating lightweight products that reduce transportation energy.

This aligns with the growing demand for environmentally responsible business practices.

Choosing the Right Manufacturer

Not all extruded plastics are the same. The quality depends on the material used, the precision of the process, and the ability to deliver consistent bulk orders. When choosing a supplier, businesses should look for:

- Experience in custom extrusion across industries.

- Capacity for bulk production without quality issues.

- Ability to deliver within timelines.

- Options for customisation in size, colour, and material.

Working with the right partner ensures businesses not only get reliable materials but also avoid future performance issues.

The Future of Custom Extruded Plastics

With industries demanding lightweight and strong solutions, the role of extruded plastics is only set to grow. New materials are being developed that improve durability while keeping costs low. At the same time, advanced manufacturing methods allow even more complex designs to be produced at scale.

In India, the demand is rising as industries expand and require efficient supply chains. Whether it is for construction, automotive, or electronics, extrusion continues to provide the balance of strength, cost, and design flexibility that modern businesses require.

FAQs

Q1. What is custom extruded plastic used for?

It is widely used in construction, automotive, electrical, furniture, and packaging industries for profiles, seals, trims, and protective covers.

Q2. Why is it better than metal or wood in some cases?

Extruded plastic is lighter, resistant to corrosion, and easier to mould into complex designs. It also reduces long-term maintenance costs.

Q3. Can custom extruded plastic be ordered in bulk?

Yes, the extrusion process is designed for continuous production, making it suitable for bulk orders with consistent quality.

Q4. How does it help reduce waste and costs?

Extrusion uses only the required material, minimises scrap, and lowers transportation costs due to lighter weight.

Q5. What should businesses check before selecting a supplier?

They should ensure the supplier has the capacity for large-scale production, uses high-quality raw material, and offers customisation options.