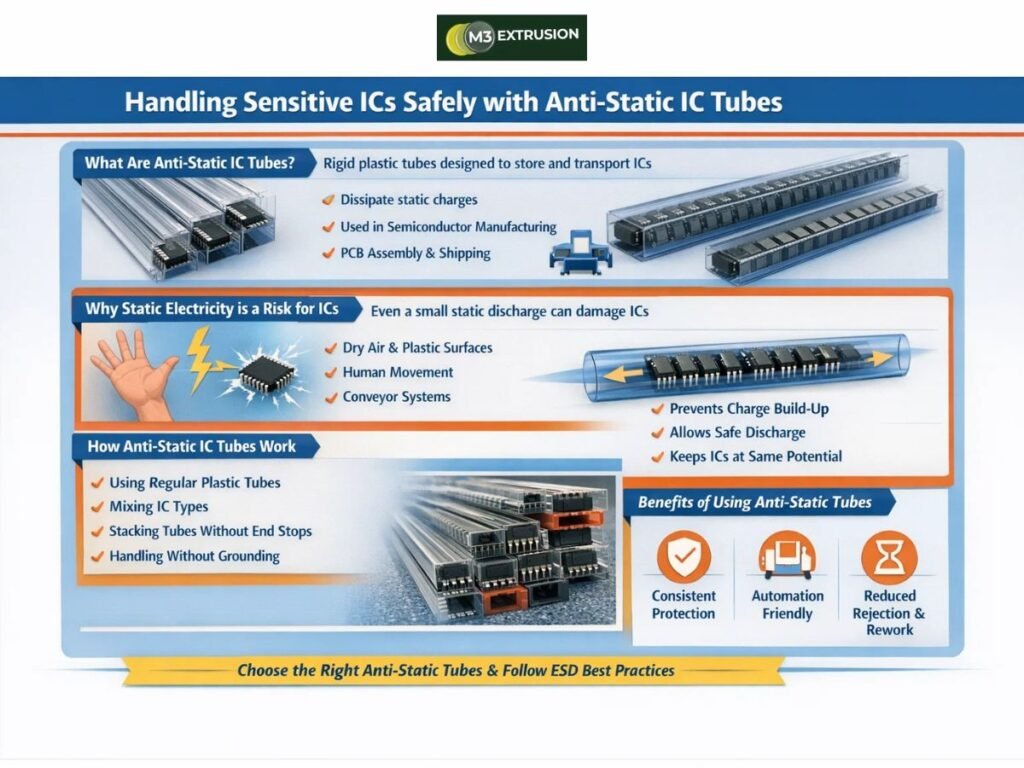

Anyone who has handled electronic components on a production floor knows how fragile integrated circuits really are. One small static discharge, often unnoticed, can damage an IC before it ever reaches the assembly line. In India, demand for anti-static IC tubes has increased as electronics manufacturing scales up and quality control becomes stricter. These tubes are not packaging add-ons. They are part of the protection system that keeps components usable from factory to final assembly.

This article explains how anti-static IC tubes work, common handling mistakes, and how to use them correctly in real production environments.

What Are Anti-Static IC Tubes

Anti-static IC tubes are rigid plastic extrusion profiles designed to store, transport, and feed integrated circuits safely. They control electrostatic discharge by dissipating static charges instead of allowing them to build up.

They are commonly used in:

- Semiconductor manufacturing

- PCB assembly lines

- Automated pick and place systems

- Component storage and shipping

Their role is simple but critical: keep sensitive ICs protected until they are installed.

Why Static Electricity Is a Serious Risk for ICs

Static electricity is often invisible, but its impact is not.

Even a discharge as low as 100 volts can damage modern ICs. A human body can carry thousands of volts without feeling it. That gap is where most failures happen.

Common sources of static include:

- Dry air conditions

- Plastic surfaces

- Human movement

- Conveyor systems

Anti-static IC tubes reduce this risk by allowing charges to bleed away safely.

How Anti-Static IC Tubes Work

These tubes are made using controlled plastic compounds with surface resistivity designed to dissipate charge.

Instead of insulating the IC completely, the tube:

- Prevents charge accumulation

- Allows slow discharge

- Keeps all components at the same electrical potential

This controlled behaviour protects IC pins and internal circuitry during handling and transport.

Common Mistakes When Handling ICs Without Proper Tubes

From real production environments, most IC damage does not happen during use. It happens during storage or movement.

Mistakes include:

- Using regular plastic tubes instead of anti-static ones

- Mixing IC types in the same tube

- Stacking tubes without end stops

- Handling tubes without grounding

Each of these increases the chance of electrostatic discharge or physical damage.

Benefits of Using Anti-Static IC Tubes in Production

Consistent Protection Across Batches

Anti-static IC tubes ensure every IC experiences the same handling conditions. This consistency matters when production runs are long and repeatable.

Compatibility with Automation

Most IC tubes are designed to work with:

- Feeders

- Loaders

- Conveyor rails

This allows smooth integration into automated assembly lines.

Reduced Rejection and Rework

When ICs arrive undamaged, testing failures drop. This saves time, labour, and material cost.

Selecting the Right Anti-Static IC Tube

Not all IC tubes perform the same way.

When selecting tubes, consider:

- IC package type and size

- Tube internal dimensions and tolerance

- Surface resistivity rating

- End cap design

A tube that is too loose can cause movement damage. A tube that is too tight can stress pins.

Storage and Handling Best Practices

Even the best tube needs proper handling.

Follow these steps:

- Always ground operators and work surfaces

- Use original end caps during storage

- Store tubes in ESD safe areas

- Avoid mixing different IC types

These small practices significantly reduce failure rates.

Real-World Manufacturing Insight

In high-volume electronics production, IC damage often shows up weeks later as field failures. That delay makes root cause analysis difficult.

Manufacturers who switch to properly specified anti-static IC tubes often report:

- Lower scrap rates

- Better assembly consistency

- Fewer unexplained test failures

Suppliers like M3 Extrusion work with electronics manufacturers to produce IC tubes based on exact package dimensions, ensuring repeat supply for automated lines.

When to Replace or Requalify IC Tubes

Anti-static properties can degrade over time.

Requalification is needed if:

- Tubes show surface wear

- Static control tests fail

- IC damage increases unexpectedly

Periodic checks help maintain protection standards.

Key Takeaways

Anti-static IC tubes are not optional in modern electronics manufacturing. They are part of the quality system.

Choosing the right tube, handling it correctly, and maintaining ESD discipline protects sensitive components and supports stable production.

FAQs About Anti-Static IC Tubes

What makes anti-static IC tubes different from regular plastic tubes

Anti-static IC tubes are made with materials that dissipate static charges instead of trapping them. Regular plastic tubes can accumulate static electricity, which increases the risk of electrostatic discharge and IC damage during handling and transport.

Are anti-static IC tubes reusable

Yes, most anti-static IC tubes are reusable if handled correctly. They should be inspected regularly for wear and tested for static control properties to ensure they continue to protect sensitive components effectively.

How do I know if an IC tube is truly anti-static

Proper anti-static IC tubes have defined surface resistivity ranges and are tested for ESD performance. Reputable manufacturers provide technical specifications or test data to confirm static dissipative behaviour.

Can anti-static IC tubes be customised for different IC packages

Anti-static IC tubes can be produced in custom sizes and profiles to match specific IC packages. Customisation ensures proper fit, reduces movement, and supports automated feeding systems.

Do anti-static IC tubes work in humid environments

Yes, anti-static IC tubes perform well in humid conditions, but grounding and ESD controls are still necessary. Humidity alone does not eliminate static risks in electronics manufacturing.

How often should anti-static IC tubes be tested

Testing frequency depends on usage and environment. In high-volume production, periodic checks every few months help ensure static control performance remains within acceptable limits.

Summary

Anti-static IC tubes play a critical role in protecting sensitive electronic components throughout storage, transport, and assembly. By controlling electrostatic discharge, they help prevent hidden damage that can lead to testing failures or field issues later. Choosing the right tube size, material properties, and handling practices ensures consistent protection, smoother automation, and lower rejection rates in electronics manufacturing.