Over the years, co-extruded PVC has become immensely popular and is being used across many industrial products that face daily wear. Made by forming two or more PVC layers into a single profile, this material is designed to handle tough working conditions. Each layer serves a clear function, which helps products perform better during regular use.

From factory equipment and cable systems to protective trims and panels, co-extruded PVC in India is being chosen for its ability to handle stress over time. Industrial settings often involve friction, load, moisture, and repeated movement. Materials that cannot manage these conditions tend to fail early and need frequent replacement.

Co-extruded PVC addresses this challenge through its layered structure. The outer layer helps protect against surface damage, while the inner layer supports strength and shape. This balance allows products to stay stable even after long periods of use.

Not only does this reduce wear, but it also supports longer product life. For industries focused on durability and consistent performance, co-extruded PVC offers a dependable material option.

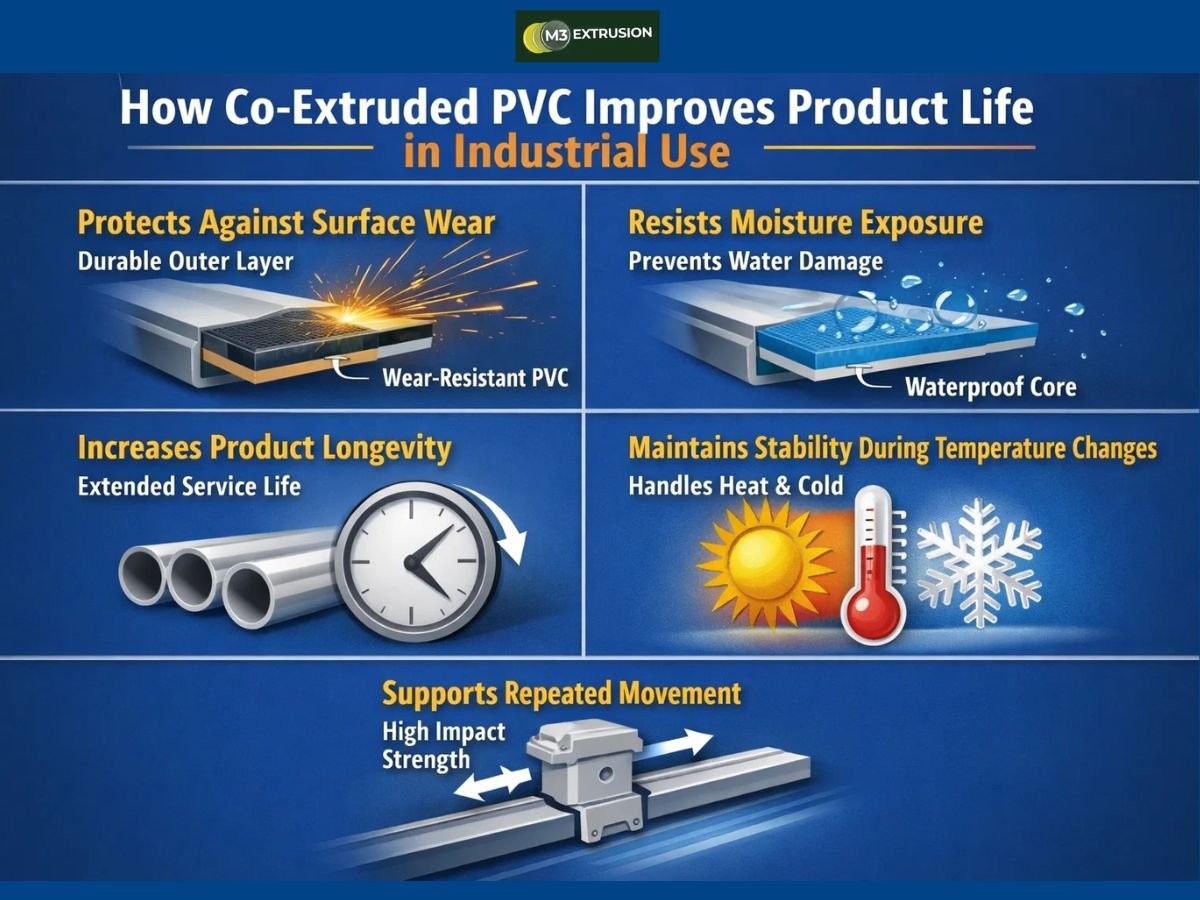

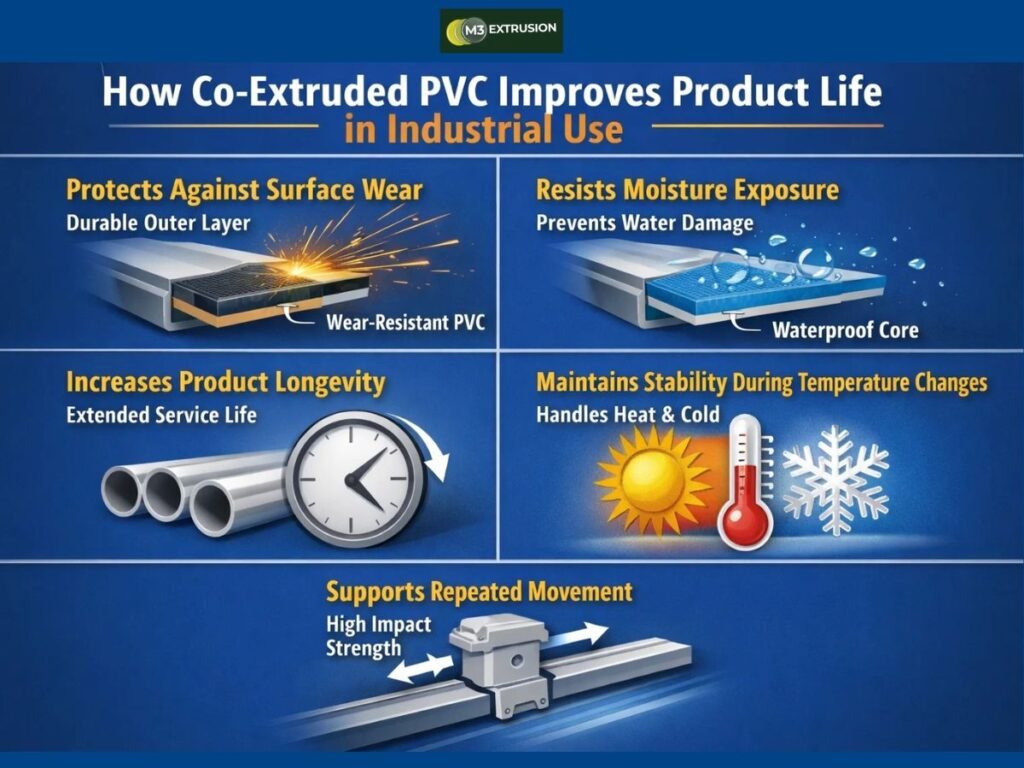

5 Ways Co-Extruded PVC Improves Product Life in Industrial Use

In industrial environments, co-extruded PVC is often chosen for products that must perform reliably over time because it maintains form and function during regular operation. Daily use in factories, plants and work sites places steady pressure on product components. Repeated contact, shifting loads, and constant movement can reduce performance when materials are not suited for these conditions.

Products made with co-extruded PVC are intended for continuous use in demanding settings. The material is formed to support both surface protection and internal structure within a single profile. This allows products to remain functional during regular handling and ongoing use.

As industrial products are used day after day, material behaviour becomes more important than initial strength alone. Co-extruded PVC is designed to respond to common use demands in a controlled way. Its construction supports steady performance during routine operation without sudden changes in shape or condition.

Co-extruded PVC is also suited for use across a wide range of industrial product types. Its structure allows it to be applied in different roles while maintaining reliable behaviour during normal operation. This makes it practical for industrial use without the need for added surface layers or extra processing steps.

Here are five ways co-extruded PVC improves product life in industrial use:

Protects Against Surface Wear

Due to the fact that co-extruded PVC has a harder outer PVC layer designed to handle friction and surface contact, it helps shield products from constant contact, friction, and handling during daily industrial use.

- Reduces friction damage: The outer surface of co-extruded PVC limits abrasion caused by sliding, rubbing, or repeated contact with other parts or equipment.

- Prevents early surface breakdown: In co-extruded PVC, the outer layer handles contact stress, which helps delay cracking, scuffing, or surface thinning over time.

- Supports internal strength: By reducing surface wear, co-extruded PVC limits how much stress reaches the core, which helps the product perform as intended.

By limiting surface damage, co-extruded PVC helps industrial products stay intact, reliable, and suitable for long-term use.

Resists Moisture Exposure

In addition to protecting against surface wear, co-extruded PVC also helps limit the impact of moisture in industrial environments. Its material structure does not absorb water, which helps products remain stable when exposed to humidity, spills, or regular cleaning.

- Prevents water absorption: The composition of co-extruded PVC stops moisture from seeping into the material, which helps avoid swelling or softening.

- Reduces surface degradation: By resisting moisture contact, co-extruded PVC helps prevent surface weakening caused by damp conditions over time.

- Supports use in wet areas: The moisture-resistant nature of co-extruded PVC makes it suitable for industrial settings where washdowns or damp conditions are common.

Moisture resistance helps co-extruded PVC products remain stable and usable during long periods of operation.

Increases Product Longevity

By combining surface protection and internal support within a single profile, co-extruded PVC helps products stay usable for longer periods in industrial environments. This structure reduces the rate at which wear and stress affect performance during regular operation.

- Delays surface degradation: The outer layer of co-extruded PVC absorbs repeated contact, which slows surface breakdown during daily industrial use.

- Preserves internal structure: The inner layer of co-extruded PVC maintains shape and support, helping products continue functioning as intended over time.

- Limits material breakdown during use: The composition of co-extruded PVC resists cracking, deformation, and surface fatigue during regular industrial operation, which slows material breakdown and helps products remain usable for longer periods.

Co-extruded PVC helps industrial products deliver greater value over their service life without the need for added treatments.

Maintains Stability During Temperature Changes

Co-extruded PVC helps products remain stable when temperatures vary in industrial environments. This stability helps prevent changes in shape or fit during regular operation.

- Limits expansion and contraction: Co-extruded PVC responds gradually to temperature changes, which helps reduce sudden size shifts during operation.

- Prevents loss of fit: Controlled thermal behaviour in co-extruded PVC helps parts maintain proper alignment and fit when exposed to heat or cold.

- Reduces temperature-related stress: It helps manage temperature-related movement within co-extruded PVC, which reduces internal stress and supports stable performance during long periods of industrial operation.

Co-extruded PVC helps industrial products remain stable and functional across common temperature changes found in everyday industrial use.

Supports Repeated Movement

Because co-extruded PVC is built to handle ongoing motion, it is well-suited for industrial products that move, slide, or adjust during regular use. This makes it a practical choice for components exposed to frequent handling or repeated operational cycles.

- Handles ongoing motion: Co-extruded PVC allows parts to move repeatedly without cracking, splitting or losing shape during routine operation.

- Spreads Movement Stress: It absorbs movement evenly, which reduces pressure build-up in specific contact areas during regular industrial use.

- Preserves fit during use: Co-extruded PVC helps components stay aligned even when movement occurs frequently.

By supporting repeated movement, co-extruded PVC helps industrial products continue operating reliably over extended periods.

Co-extruded PVC helps industrial products remain dependable over long periods of regular use. Its structure helps products handle wear, movement, moisture and temperature changes without losing function.

This steady performance supports longer service periods and reduces disruption caused by early failure. When materials remain stable under daily operating pressure, products are easier to manage and more dependable over time.

Choosing co-extruded PVC allows industrial components to handle everyday use without relying on added treatments or frequent replacement. As a result, manufacturers and operators benefit from products that stay reliable, predictable, and fit for long-term operation in demanding environments.

Are you looking for reliable co-extruded PVC profiles in India built for long-term industrial use? M3 Extrusion offers custom co-extruded PVC profiles designed to handle wear, movement, moisture, and demanding operating conditions.

Frequently Asked Questions

How to choose the right co-extruded PVC manufacturer for industrial use?

Make sure you choose a co-extruded PVC manufacturer with proven industrial experience, as this helps ensure the material is produced for real use conditions. Also, check whether the manufacturer follows consistent production practices, maintains layer accuracy, and provides clear product specifications.

Can co-extruded PVC be customised for specific industrial products?

Yes, co-extruded PVC can be adapted to suit different product needs. Layer composition, profile shape, and finish can be adjusted to match use conditions without changing the basic structure or adding separate materials.

How does co-extruded PVC differ from single-layer PVC?

Co-extruded PVC combines multiple layers in one profile, while single-layer PVC uses one compound. This difference affects how products respond to stress, contact, and long-term industrial use conditions today.

Where is co-extruded PVC commonly used in industrial settings?

It is used in cable systems, trims, guards, panels, and support profiles. These applications require steady material behaviour during repeated use and exposure without relying on frequent replacement or surface treatment.

Are co-extruded PVC products easier to maintain in industrial use?

Co-extruded PVC products are generally easier to maintain because they do not require surface treatments or frequent repairs. Routine cleaning and basic checks are usually enough to keep them usable during regular industrial operation.

Check related articles for more insights:

- How Co-Extruded PVC Supports Custom Design and Large-Scale Supply

- Reducing Production Waste Through Accurate Plastic Co-Extrusion Design

- The Benefits of Plastic Co-Extrusion in Window, Lighting, and Sealing Systems