In today’s industries, companies look for materials that are strong, reliable, and cost-effective. One such option is co-extruded PVC in India. It is widely used because it combines different properties into one product, making it suitable for a wide range of applications. More importantly, it can be manufactured in large quantities, which makes it ideal for businesses that need regular supply in bulk.

What is Co-Extrusion in PVC?

Co-extrusion is a process in which two or more types of PVC are joined together during production. Instead of making a single-layer profile, different layers are combined into one product.

For example:

- A rigid layer adds support and keeps the profile in shape.

- A flexible layer helps with sealing or bending.

- A protective layer can resist weather, UV rays, or chemicals.

By using this method, manufacturers can design profiles that are not only strong but also adaptable to different conditions.

Why Do Industries Use Co-Extruded PVC?

1. Customisation Options

Industries often need profiles that match specific requirements. With co extrusion, profiles can be designed in custom colours, shapes, and sizes. Businesses can also combine hard and soft layers in the same product. This is very useful in cases where strength and flexibility are needed together.

2. Cost-Effective Manufacturing

Because multiple layers are combined in a single process, there is no need for additional assembly. This reduces production costs, especially for bulk supply. Companies save time, material, and labour, making it a more efficient choice.

3. Consistent Quality

Modern extrusion machines ensure that every profile is uniform. Whether a company orders a few hundred metres or several tonnes, the quality and dimensions remain consistent. This is very important for industries like construction and automotive, where accuracy matters.

4. Durability

Co-extruded PVC profiles last longer than single-layer profiles. The protective outer layers help them resist sunlight, dust, heat, and moisture. This ensures long-term performance even in challenging conditions.

Applications of Co-Extruded PVC

Co-extruded PVC is popular across many industries because it is so versatile.

- Construction – Used in window seals, trims, weatherstrips, and gaskets that block water, air, and dust.

- Automotive – Applied in door seals, window channels, and trims that reduce noise and vibration.

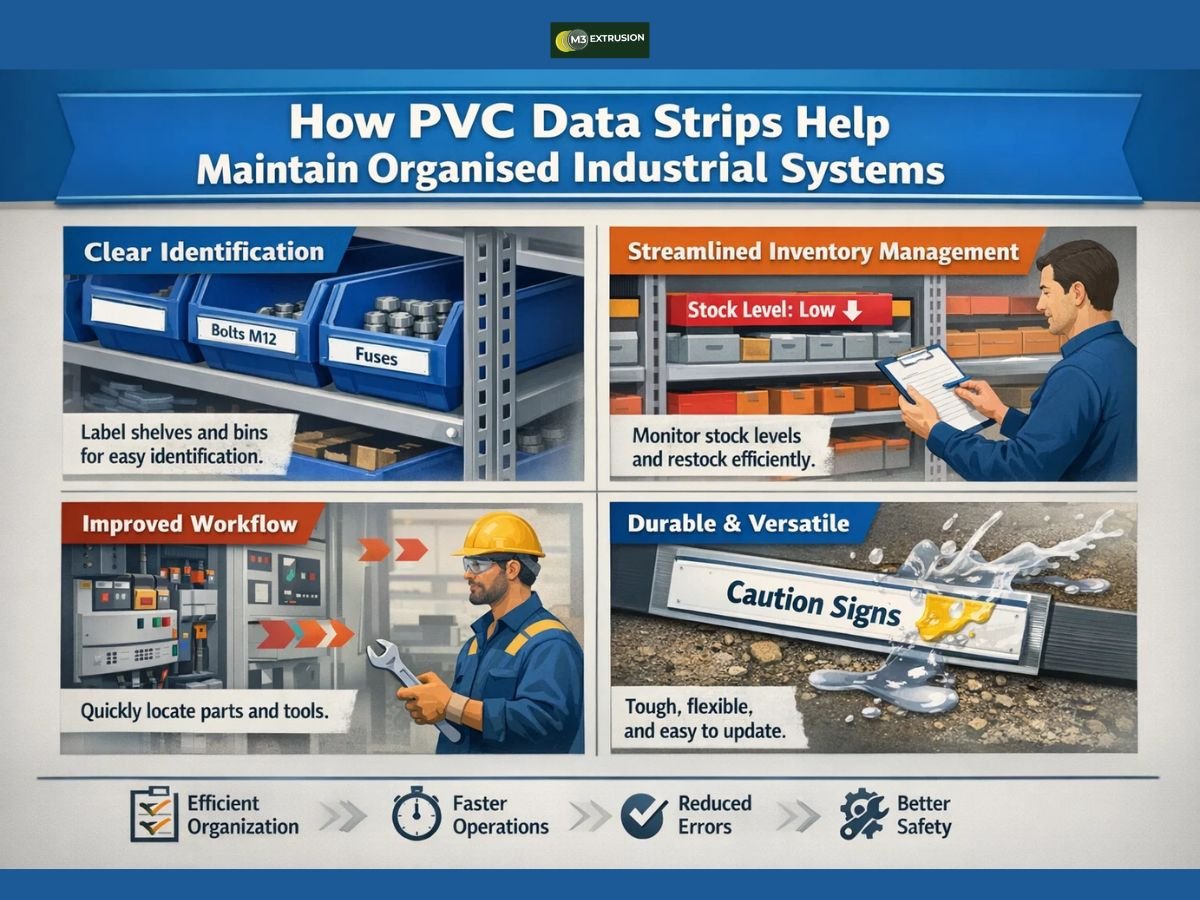

- Retail and Displays – Shelf-edge strips, price tags, and product display profiles that look neat and professional.

- Furniture – Decorative trims and edge bands that provide both style and strength.

- Electrical and Electronics – Profiles for insulation and cable management that improve safety.

- Packaging – Protective profiles that keep goods safe during shipping.

This wide range of uses shows why co-extruded PVC is an important material for manufacturers.

Benefits for Bulk Supply

For businesses that require regular supply in large quantities, co-extruded PVC offers clear benefits:

- High-speed production – Modern extrusion lines can produce large volumes quickly.

- Reduced waste – Since profiles are produced in one step, extra parts or adhesives are not required.

- Reliability – Bulk orders are delivered with consistent quality.

- Sustainability – Many manufacturers use recycled PVC for eco-friendly options.

This combination of speed, quality, and sustainability makes co-extruded PVC the right choice for businesses working on large projects.

How Co-Extrusion Helps in Custom Design

Co extrusion is not only about strength and bulk supply; it also supports creative design.

- Dual hardness – Hard and soft materials can be combined in one profile.

- Multi-colour designs – Different colours can be added without painting.

- Weather resistance – UV layers keep outdoor profiles from fading or cracking.

- Complex shapes – Special tools allow unique designs for specific industries.

This flexibility gives designers and engineers more freedom while keeping the product practical.

Importance of Reliable Suppliers

Choosing the right supplier ensures businesses receive quality products on time. Suppliers with advanced facilities can handle both small custom orders and large-scale requirements.

For example, M3 Extrusion provides co-extruded PVC profiles that meet industry standards and support bulk supply needs. Their focus on quality and consistency makes them a dependable partner for industries in construction, automotive, and retail.

Growing Trends in Co-Extruded PVC

The demand for co-extruded PVC is rising because industries are looking for more efficient solutions. Some of the current trends include:

- Eco-friendly materials – Using recycled and recyclable PVC.

- Fire-resistant profiles – Safer materials for construction and public spaces.

- Antimicrobial layers – Useful in healthcare and food industries.

- High-precision finishes – For industries that need exact measurements.

These trends show how co-extrusion is adapting to modern requirements.

How Businesses Can Source High-Quality Profiles

For companies looking to source profiles, it is important to check:

- The supplier’s production capacity.

- The consistency of quality in bulk orders.

- The ability to create custom designs.

- Their track record with B2B clients.

Many industries today focus on reliable suppliers who can provide both large-scale production and design flexibility. Businesses in India often seek ways to get high-quality co-extruded PVC profiles in bulk so they can manage costs and ensure smooth supply chains.

FAQs

1. What makes co-extruded PVC different from normal PVC?

It combines different layers in one product, offering both strength and flexibility.

2. Can it be used outdoors?

Yes, with protective UV layers, it performs well in outdoor applications.

3. Is it suitable for bulk supply?

Yes, co-extrusion supports high-volume production while keeping quality consistent.

4. Which industries use it the most?

It is widely used in construction, automotive, furniture, electrical, and retail displays.

5. Are eco-friendly options available?

Yes. Many suppliers provide recyclable and low-impact versions of PVC profiles.

Conclusion

Co extruded PVC is a strong and flexible solution that supports both custom design and bulk supply. It allows businesses to save costs, reduce waste, and meet industry needs without compromise. With applications across many industries and growing demand for eco-friendly options, it will continue to play an important role in manufacturing and large-scale supply.