In modern industrial and commercial applications, clear and durable materials are essential. The PMMA transparent profile in India has become a popular choice for manufacturers looking for components that combine optical clarity with mechanical strength. These profiles are widely used in industries ranging from electronics and lighting to retail displays and signage, thanks to their ability to deliver long-lasting performance while maintaining excellent transparency.

PMMA profiles help reduce material fatigue, resist yellowing, and provide a lightweight yet strong alternative to glass. This makes them ideal for applications where both visibility and durability are critical.

For readers who want a quick look at how PMMA profiles support clarity and strength in real production settings, this practical PMMA guide explains their main uses in a simple way.

Why PMMA Transparent Profiles Are Essential in Modern Production

PMMA, also known as acrylic, offers several advantages over traditional glass and other plastics:

- High clarity – up to 92% light transmission

- Impact resistance – stronger than standard glass

- Lightweight – easier handling and installation

- UV resistance – maintains clarity under sunlight

- Chemical stability – resistant to many industrial chemicals

These qualities make PMMA profiles suitable for applications such as machine covers, protective panels, signage, lighting diffusers, and display cases.

Key Benefits of Using PMMA Profiles

1. Enhanced Optical Clarity

The transparency of PMMA allows operators to monitor processes and machinery easily. Unlike glass, PMMA does not shatter easily, making it safer for industrial environments.

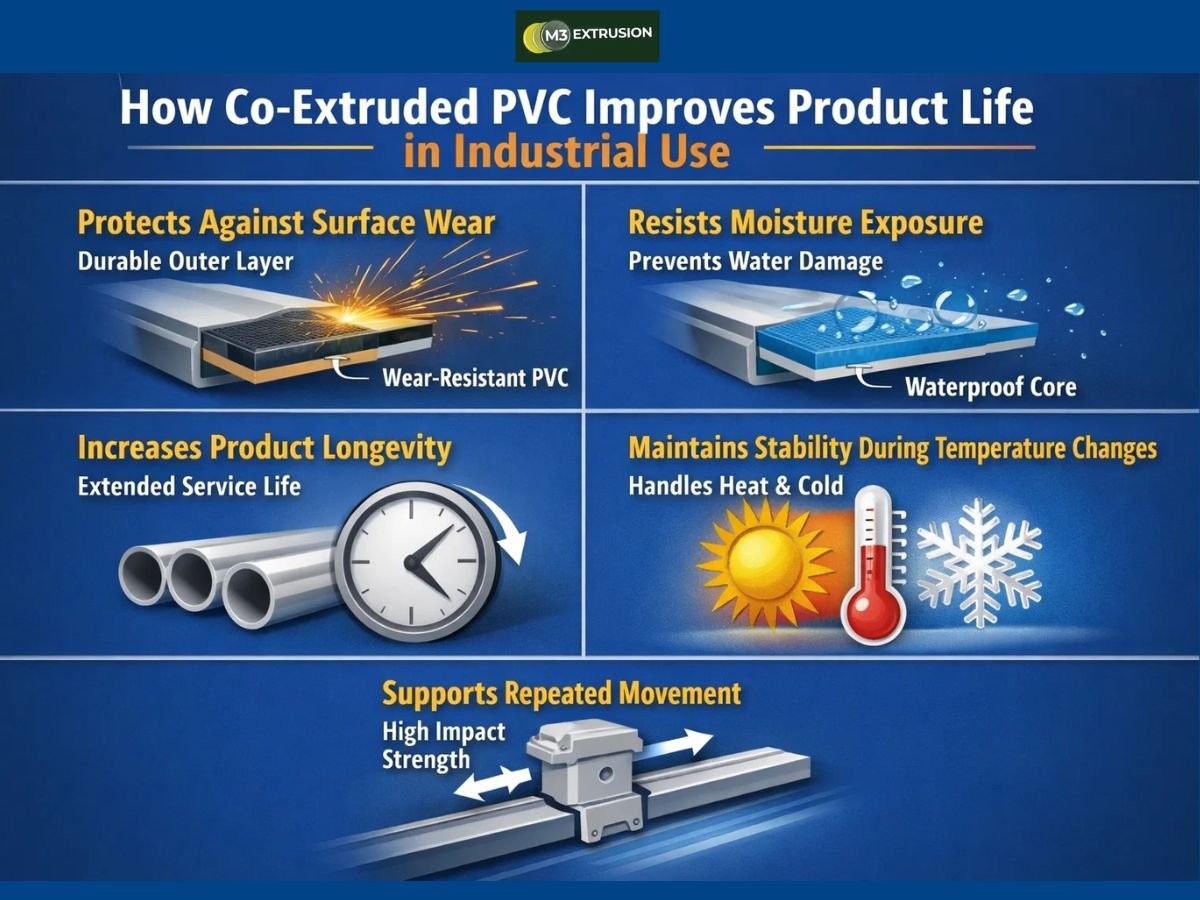

2. Durability and Strength

PMMA profiles can handle moderate impact without cracking, providing a long service life. Their rigidity helps in maintaining structural integrity, even under continuous use.

3. Lightweight and Easy to Install

Installation is faster and safer compared to heavier glass panels. This reduces labour costs and simplifies assembly in production lines.

4. Versatile Applications

From protective guards in factories to display units in retail, PMMA profiles can be customised to fit almost any shape or size, offering flexibility in design.

Practical Industrial Uses of PMMA Transparent Profiles

Electronics and Instrumentation

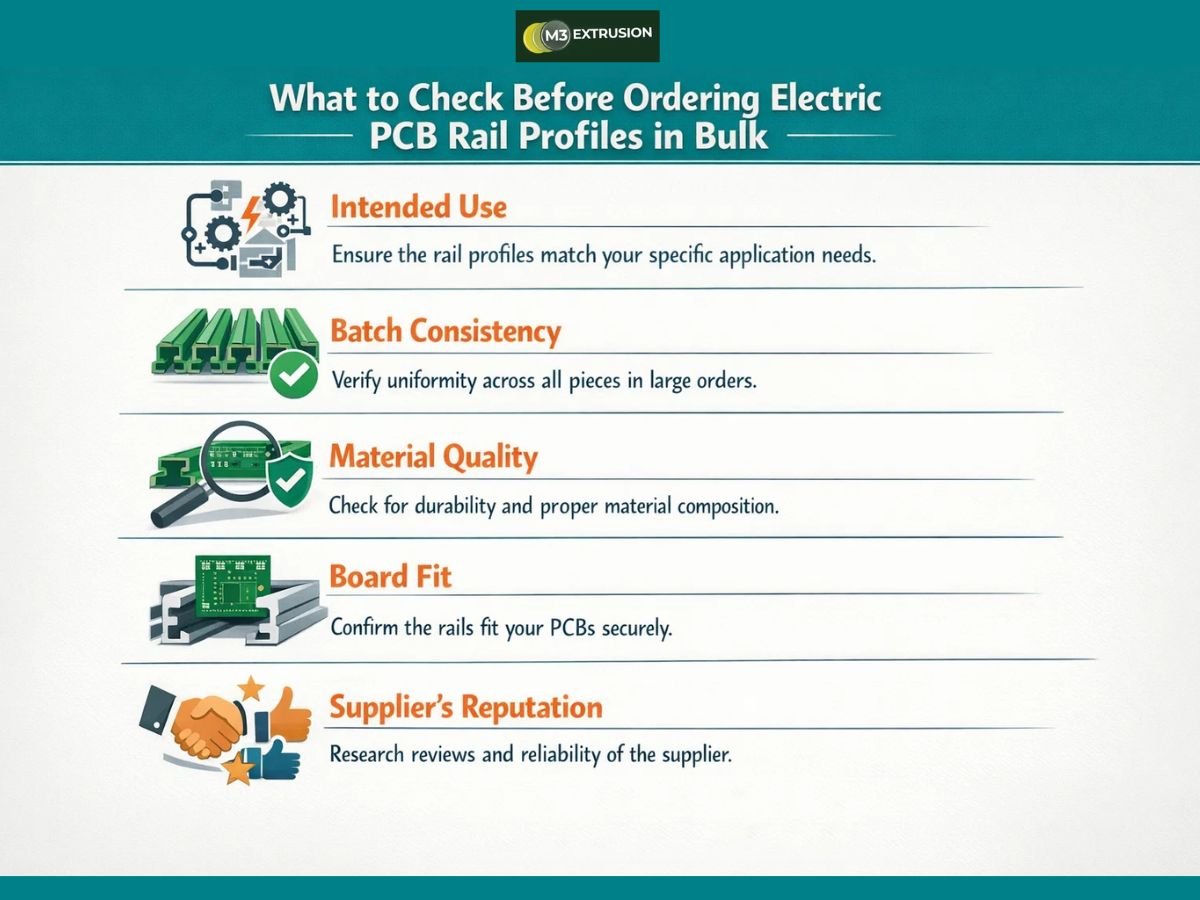

- Protective covers for circuit boards and instruments

- Clear housings for electronic panels

Lighting and Displays

- LED diffusers and lighting enclosures

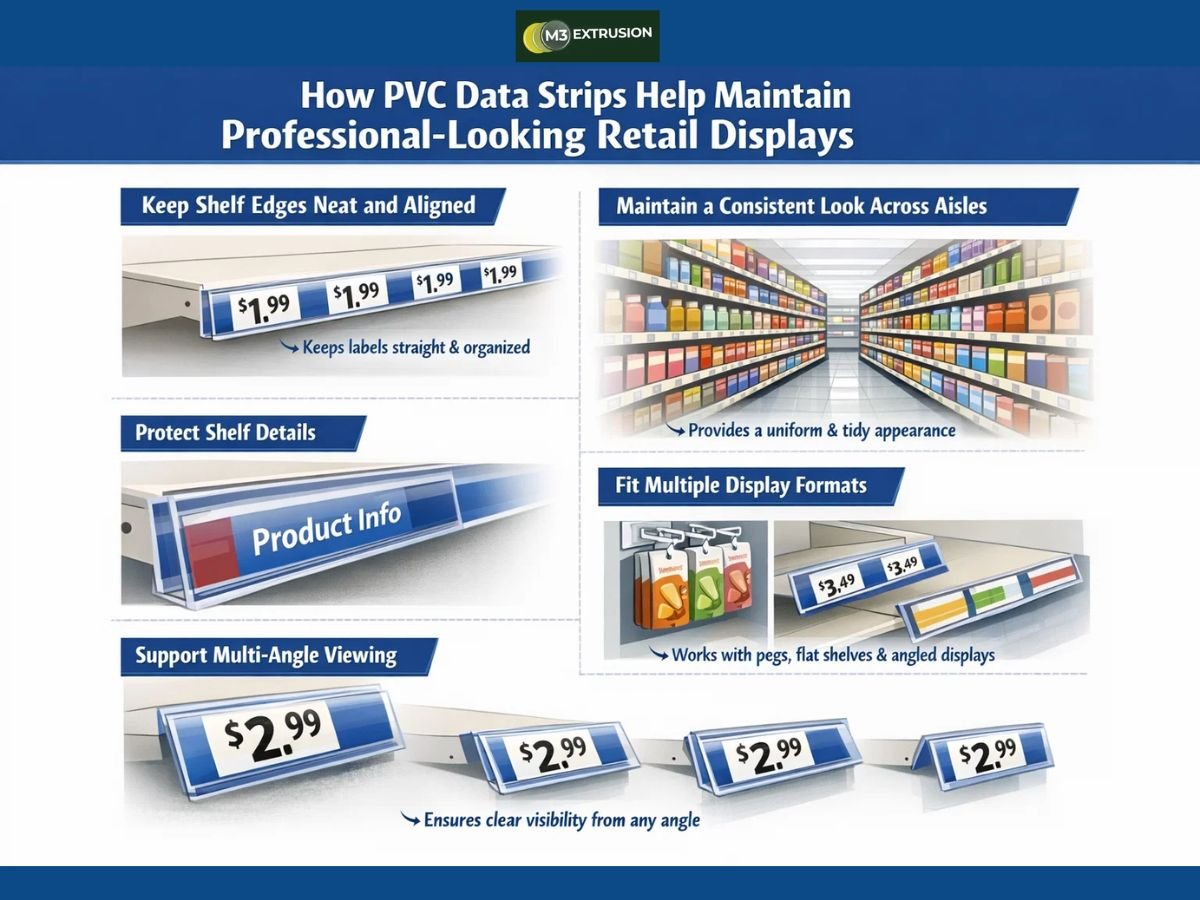

- Exhibition and retail display panels

Machine Guards and Safety Shields

- Transparent shields for moving machinery

- Guards that allow monitoring while ensuring safety

Architectural and Commercial Applications

- Transparent partitions

- Signage and information panels

Why Industries in India Are Adopting PMMA Profiles

The Indian market is increasingly using PMMA transparent profiles due to their cost-efficiency, durability, and ease of fabrication. Local manufacturers can supply bulk orders while maintaining consistent quality, making PMMA profiles a practical solution for industrial and commercial projects.

Short lead times, reliable performance, and low maintenance requirements make them a preferred choice for sectors like electronics, manufacturing, retail, and food processing.

Industries in India prefer PMMA transparent profiles because of their durability, cost efficiency, and compatibility with modern production practices. Companies like M3 Extrusion support industrial users with custom-made solutions, bulk manufacturing options, and consistent quality that aligns with industrial standards.

These profiles also help businesses achieve:

- More reliable machine protection

- Longer-lasting installations

- Lower maintenance requirements

- Better visibility in safety-critical zones

Tips for Selecting the Right PMMA Transparent Profile

- Assess Clarity Requirements – Determine if high light transmission or diffused light is needed.

- Choose Appropriate Thickness – Thicker profiles provide more strength, while thinner profiles reduce weight.

- Consider UV Exposure – Use UV-stabilised grades for outdoor applications.

- Check Chemical Compatibility – Ensure resistance to cleaning agents or chemicals used in production.

- Verify Customisation Options – Profiles can be extruded into complex shapes to fit specific needs.

How PMMA Profiles Support Efficient Production

Using PMMA profiles ensures:

- Safer work environments due to break-resistant panels

- Easy monitoring of machinery through clear sections

- Reduced maintenance costs compared to glass or fragile plastics

- Long-term stability and minimal yellowing, even under exposure to light or chemicals

These advantages help factories and commercial setups maintain productivity while safeguarding both equipment and staff.

FAQ Section

1. What is a PMMA transparent profile?

A PMMA transparent profile is an extruded acrylic section that combines clarity with strength. It is widely used in industrial, commercial, and architectural applications where visibility and durability are essential.

2. Why is PMMA transparent profile in India popular?

It is popular because it provides high clarity, impact resistance, UV stability, and lightweight handling. Indian manufacturers also offer customised sizes and bulk supply options to meet diverse industrial needs.

3. Can PMMA profiles replace glass in industrial applications?

Yes. PMMA profiles are safer, lighter, and less prone to shattering than glass. They maintain transparency while providing strength and durability in industrial settings.

4. Which industries benefit most from PMMA profiles?

Electronics, manufacturing, retail displays, lighting, and architectural projects benefit most due to the combination of visibility, durability, and easy installation.

5. How should PMMA profiles be maintained?

Clean with mild, non-abrasive solutions. Avoid strong solvents or rough scrubbing, which may scratch or damage the surface. Proper maintenance ensures long-term clarity and performance.