Energy efficiency research has shown that windows contribute as much as 30% of a building’s heat loss. Although double or triple glazing makes a difference, it’s not only about the glass. It’s also about what is between the panes. That’s where the warm edge spacer quietly comes in.

It may not seem like much, but this tiny piece of hardware does big things to enhance insulation, lower energy costs, and help buildings pass today’s more stringent building codes. As green buildings continue to make inroads across the globe, particularly in rapidly expanding markets such as India, knowing how warm edge spacers assist with compliance has never been more vital.

Let’s take a closer look and explore how this tiny bit of technology keeps buildings up to speed, compliant, and energy intelligent.

What Is a Warm Edge Spacer?

Before we go too far, let’s break it down quickly. A warm edge spacer is a thin piece of material inserted between the panes of double or triple-glazed windows. It isolates the glass layers and prevents the insulating gas (such as argon) from escaping.

However, in contrast to conventional aluminium spacers that freely transfer heat, warm-edge spacers are constructed from materials that inhibit thermal transfer, such as composite plastics or stainless steel. This easy change offers enormous advantages regarding energy efficiency and conformity to current building standards.

Why Modern Building Standards Care About Energy Efficiency?

Codes for building these days are not merely about safety but also about sustainability. Nations worldwide are revising their standards to minimize carbon prints, encourage energy efficiency, and facilitate green buildings.

In India, for example, the Energy Conservation Building Code (ECBC) encourages improved insulation, reduced U-values (thermal transmittance), and intelligent building envelopes. And guess what? Warm edge spacers in India check all those boxes.

How Warm Edge Spacers Help Buildings Stay Compliant?

Here’s how this small innovation assists you in being on the right side of contemporary codes:

- Minimizes Heat Loss Through Windows

Old-style aluminium spacers function as small roads for heat to travel. Warm edge spacers, however, provide a thermal break. That is, less heat leaks out in the winter and less heat gets in during the summer. This makes buildings achieve energy efficiency standards more easily and decreases reliance on air conditioning or heaters. - Facilitates Lower U-Values

One of the key metrics in modern building standards is the U-value. The lower the U-value, the better the insulation. Using warm edge spacers improves the overall U-value of your window units. That directly helps in aligning with the latest green building certifications like LEED, BREEAM, or IGBC in India. - Prevents Condensation

Did you ever notice foggy windows with water drops at the edges? That’s condensation, and that is an indicator of low quality in insulation. Inadequately insulated windows enable moisture buildup, which ruins frames and can also cause mold growth. Warm edge spacers make the glass edges warmer, preventing condensation from happening. This satisfies indoor air quality and durability requirements. - Enhances Comfort Indoors

Building codes today concentrate on comfort as much as on performance. Windows aren’t chilly even during colder months with warm edge spacers. No more cold drafts beside the glass. That translates to happier individuals inside and a building that meets comfort specifications. - Facilitates Sustainability Targets

Less energy used equals fewer emissions. By assisting in lowering energy bills and the carbon footprint of the building, warm edge spacers aid national and international sustainability initiatives. This simplifies the process of qualifying for green incentives and certifications.

Why Compliance Matters?

Not adhering to building codes can be expensive. In addition to increased energy costs, you could have legal problems, project delays, or even fines. That’s why incorporating compliant technologies, such as warm edge spacers, early in the design and construction process is a good idea. They’re simple to install, inexpensive in the long term, and enable you to future-proof your project.

Conclusion

In short, warm edge spacers may be compact, but they are a large part of ensuring buildings comply with today’s energy and performance regulations. From minimizing heat loss and avoiding condensation to reducing U-values and enabling green certifications, they tick all the compliance boxes.

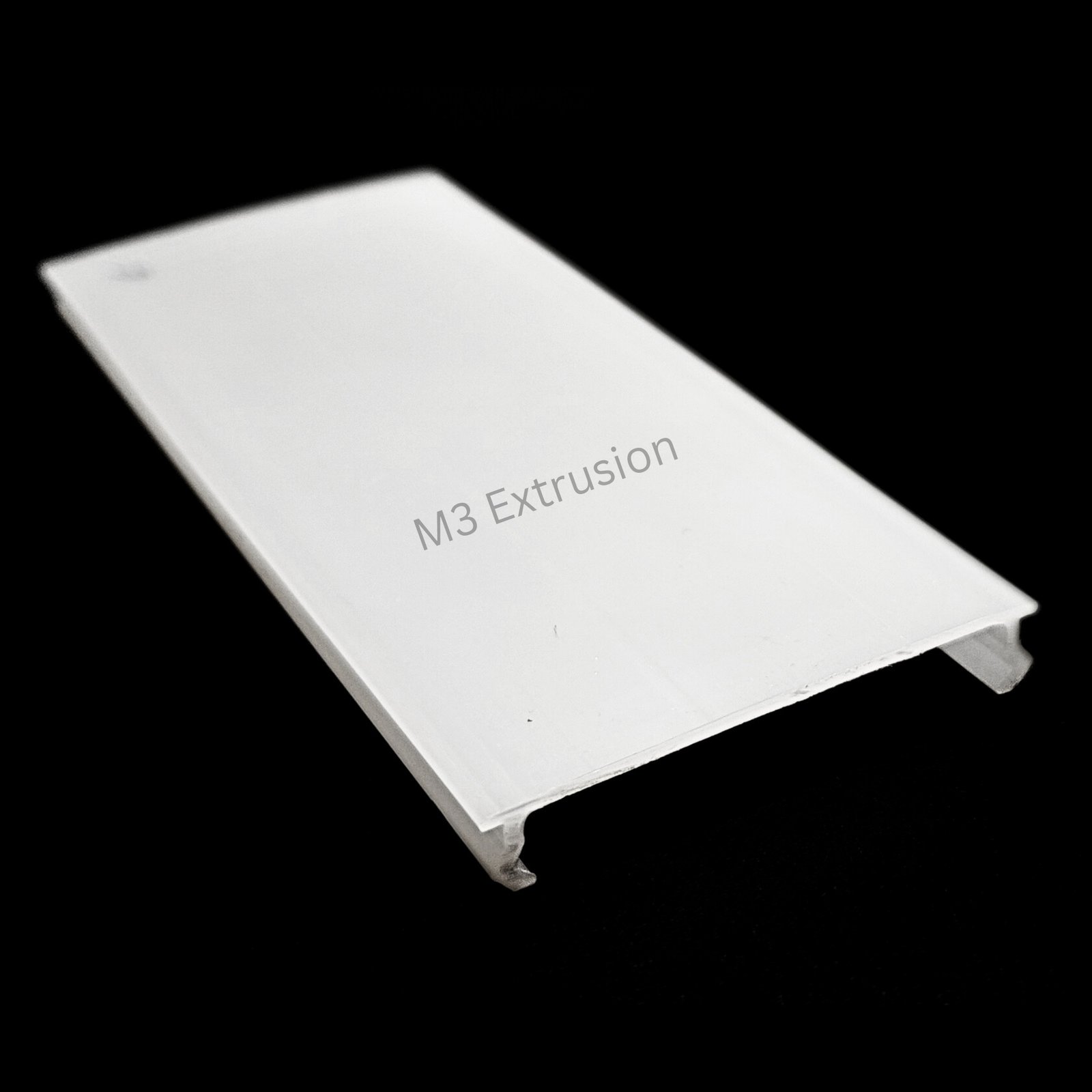

With increasing demand for sustainable construction, particularly with the increasing application of these spacers in India, these products are no longer optional. They’re a necessity. At M3 Extrusion, we provide the best warm edge spacers to suit today’s building needs and keep you ahead of the game. Let’s build better, together.

Frequently Asked Questions (FAQs)

- Are warm edge spacers more expensive than traditional spacers?

Yes, slightly. But the long-term savings on energy bills and improved comfort make them a smart investment. - Can warm edge spacers be used in any type of window?

Absolutely. They are compatible with double and triple-glazed windows across residential and commercial projects. - How long do warm edge spacers last?

They are highly durable and designed to last as long as the window unit itself, often 20 years or more. - Do warm edge spacers affect the appearance of the window?

Not at all. In fact, they give a cleaner and more uniform edge look, which many architects prefer.

- Is there a demand for warm edge spacer in India?

Yes, there is a rising demand as energy codes tighten and sustainable building practices grow across the country.