The manufacturing and construction industries in India are evolving rapidly, demanding materials that combine durability, flexibility, and cost efficiency. Among these, pvc co-extrusion in india has emerged as a highly sought-after solution for industrial and commercial applications. By integrating multiple layers of PVC into a single profile, co-extrusion technology delivers enhanced performance, longer lifespan, and adaptability for complex project requirements.

From window seals to industrial tubing, co-extruded PVC profiles offer practical benefits that help manufacturers achieve precision, reduce material waste, and meet rigorous standards in modern industrial projects.

Understanding PVC Co-Extrusion

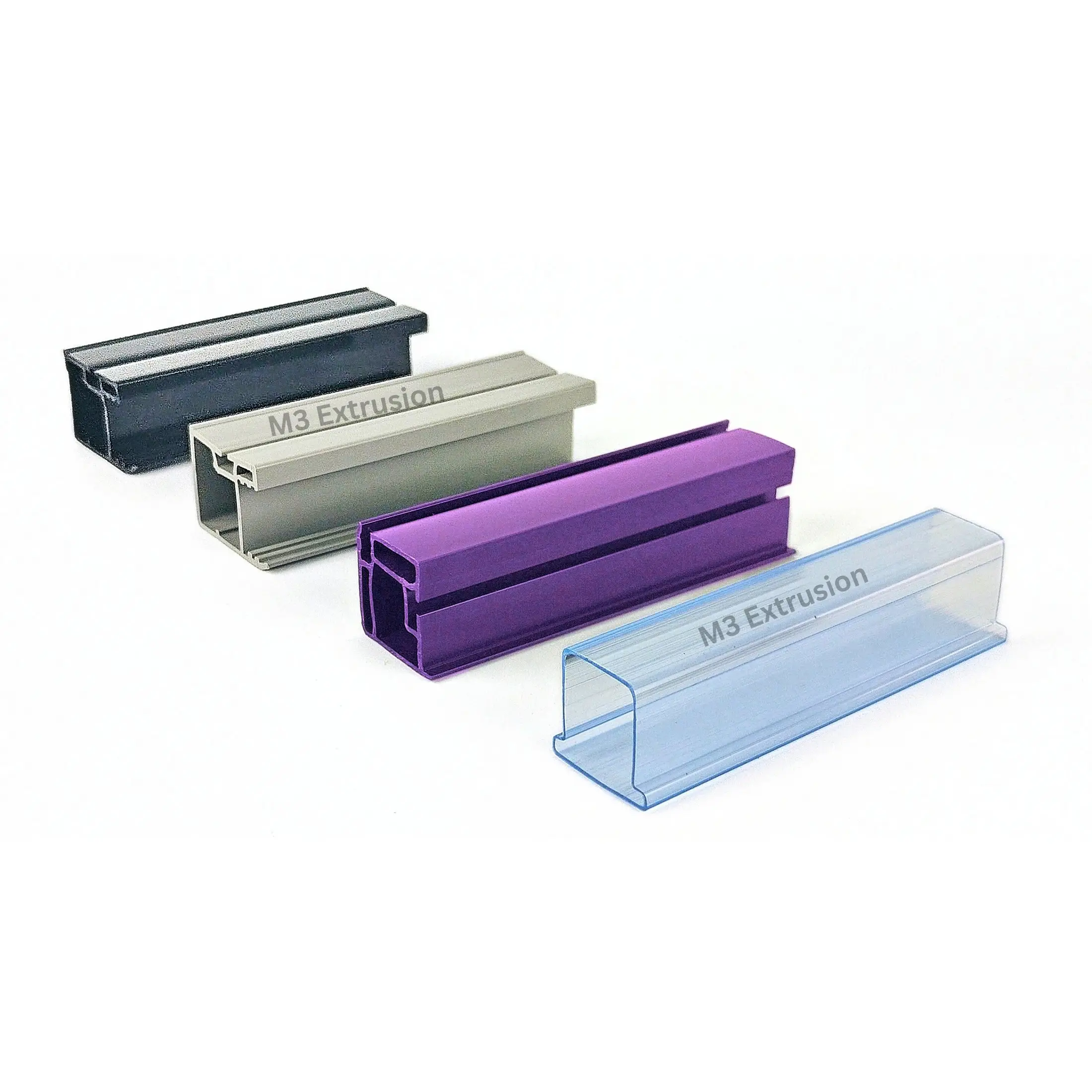

PVC co-extrusion is a manufacturing process where two or more layers of PVC are extruded simultaneously to form a single, unified profile. Each layer can be designed with distinct properties such as rigidity, flexibility, colour, or chemical resistance.

Key characteristics of co-extruded PVC profiles include:

- Multi-layer construction with functional differentiation

- Resistance to weathering, chemicals, and abrasion

- Lightweight design with structural integrity

- Custom shapes suitable for bulk manufacturing

This process enables manufacturers to create profiles that deliver multiple functional benefits in a single product, reducing the need for separate components or additional assembly.

1. Industrial Applications Driving Demand

PVC co-extrusion is widely adopted across industries due to its versatility and functional advantages.

Key applications include:

a. Construction and Architectural Profiles

- Window and door profiles that combine rigid support with flexible sealing layers

- Wall trims and skirting boards that resist wear and environmental exposure

- Flooring trims with enhanced impact resistance

Example: Builders in India increasingly choose co-extruded PVC window profiles to improve insulation, reduce noise, and ensure longer-lasting performance.

b. Automotive Components

- Door seals and gaskets providing airtight and watertight performance

- Decorative trims and protective strips with durable outer layers

- Noise and vibration dampening profiles

c. Electrical and Cable Management

- Multi-layered tubing for insulation and protection of cables

- Profiles that resist abrasion, moisture, and chemical exposure

- Custom shapes for industrial wiring applications

d. Industrial Manufacturing

- Protective covers for machinery and equipment

- Flexible yet durable seals in packaging or processing systems

Co-extruded PVC allows industries to meet the growing demand for profiles that are both functional and durable, especially in high-volume production environments.

2. Advantages of PVC Co-Extrusion

a. Enhanced Durability

Multiple layers in co-extruded PVC profiles ensure resistance to environmental stress, UV radiation, abrasion, and chemical exposure. This durability reduces the need for frequent replacements and increases product lifespan.

b. Customisation and Flexibility

Manufacturers can adjust each layer’s thickness, hardness, or colour to meet project-specific requirements. For instance, a profile may have a rigid outer layer for structural support and a soft inner layer for sealing or cushioning.

c. Cost-Effectiveness

By combining multiple functional layers in a single profile, co-extrusion eliminates the need for additional coatings, adhesives, or separate components. This reduces material costs, production time, and assembly labour.

Example: In industrial door seals, a co-extruded PVC profile replaces a separate seal and frame insert, saving both time and materials.

d. Sustainability

- Reduced material usage by integrating multiple functions in one profile

- Lower energy consumption during production

- Extended product lifespan reducing replacement frequency

Sustainable manufacturing practices are increasingly important in India, and PVC co-extrusion helps companies align with green construction and industrial standards.

3. Problem-Solving Applications

PVC co-extrusion addresses common challenges faced by industrial and construction manufacturers:

- Eliminates assembly errors caused by combining multiple parts

- Ensures uniform performance in large-scale production

- Provides reliable sealing, protection, and structural support in harsh environments

Example: In automotive door seals, co-extrusion ensures consistent flexibility and compression across every vehicle produced, reducing defects and customer complaints.

4. Technical Advantages

a. Consistent Quality

Co-extrusion ensures that every profile meets exact dimensional specifications and layer bonding requirements, which is critical for industrial applications.

b. Multi-Layer Performance

- Outer layer: Provides rigidity, abrasion resistance, or UV protection

- Inner layer: Offers flexibility, cushioning, or sealing

- Optional additional layers: Colour coding, chemical resistance, or thermal insulation

c. Bulk Production Capability

The process is suitable for large-scale manufacturing, allowing industries to meet increasing demand while maintaining uniformity across all products.

5. Market Trends and Growing Demand in India

The Indian industrial sector is witnessing rising demand for PVC co-extrusion due to:

- Increased adoption in construction for durable windows, doors, and panels

- Growing automotive production requiring high-performance seals and trims

- Expansion of electrical and industrial infrastructure needing protective profiles

Fact: Industry reports indicate a growing CAGR for PVC co-extrusion products in India, driven by urban infrastructure projects, automotive growth, and industrial expansion.

6. Practical Tips for Manufacturers

When considering PVC co-extrusion for industrial applications:

- Choose quality suppliers: Reliable manufacturers ensure consistent layer bonding and material properties.

- Determine functional requirements: Assess whether rigidity, flexibility, sealing, or aesthetic properties are primary.

- Consider bulk orders: Co-extrusion supports large-scale production efficiently, which reduces per-unit costs.

Tip: Learn more about why PVC Co-Extrusion is the answer to long-lasting and reliable seals for insights into sealing and insulation applications.

Quick Answer: Why Choose PVC Co-Extrusion?

PVC co-extrusion in India offers multi-layered profiles that combine durability, flexibility, and cost efficiency. It’s ideal for industrial applications like sealing, cable protection, automotive components, and construction profiles. Co-extrusion reduces material waste, ensures consistent quality, and provides long-lasting performance in demanding environments.

FAQs About PVC Co-Extrusion

- What is PVC co-extrusion?

PVC co-extrusion is a manufacturing process that extrudes two or more PVC layers simultaneously, producing a single profile with multiple properties like rigidity, flexibility, or colour. - Which industries use PVC co-extrusion in India?

Construction, automotive, electrical, and industrial manufacturing sectors widely use co-extruded PVC for profiles, seals, trims, and protective tubing. - What benefits do co-extruded PVC profiles provide?

They offer durability, customisation, cost efficiency, consistent quality, and long-lasting performance compared to single-layer profiles. - Can co-extruded PVC reduce material waste?

Yes. By integrating multiple functions into one profile, it eliminates the need for additional components, reducing material use and production costs. - Are co-extruded PVC profiles suitable for outdoor applications?

Absolutely. Outer layers can be designed for UV, weather, and chemical resistance, making them ideal for construction, automotive, and industrial applications. - How does co-extrusion help in bulk production?

Co-extrusion allows consistent layer bonding and uniform dimensions across large quantities, ensuring high-quality output for industrial and commercial projects.

Conclusion

The demand for PVC co-extrusion in India is steadily growing as industries seek versatile, durable, and cost-effective materials. From construction profiles to automotive seals and industrial tubing, co-extruded PVC provides multi-layered solutions that improve efficiency, performance, and sustainability. By adopting co-extrusion technology, manufacturers can meet industrial needs while reducing material waste, ensuring consistency, and achieving long-lasting, reliable results.