Over the years, PVC data strips have become immensely popular in various industries due to their strength and reliability. While extrusion, molding, and printing contribute to their durability, PVC itself plays a key role in making these strips strong and long-lasting. Industrial environments often demand materials that can withstand daily handling, mechanical stress and exposure to different conditions without compromising performance.

PVC provides the right balance of toughness and flexibility to meet these needs. Its inherent properties help data strips maintain their shape, resist wear and tear, and stay functional over time. Because of these qualities, PVC data strips in India are trusted for reliable identification, tracking, and data management in manufacturing units, warehouses, logistics and other industrial operations.

The combination of careful production processes as well as PVC’s durability ensures that these strips continue to deliver consistent performance, making them a practical and dependable choice for businesses that require long-lasting, high-quality solutions.

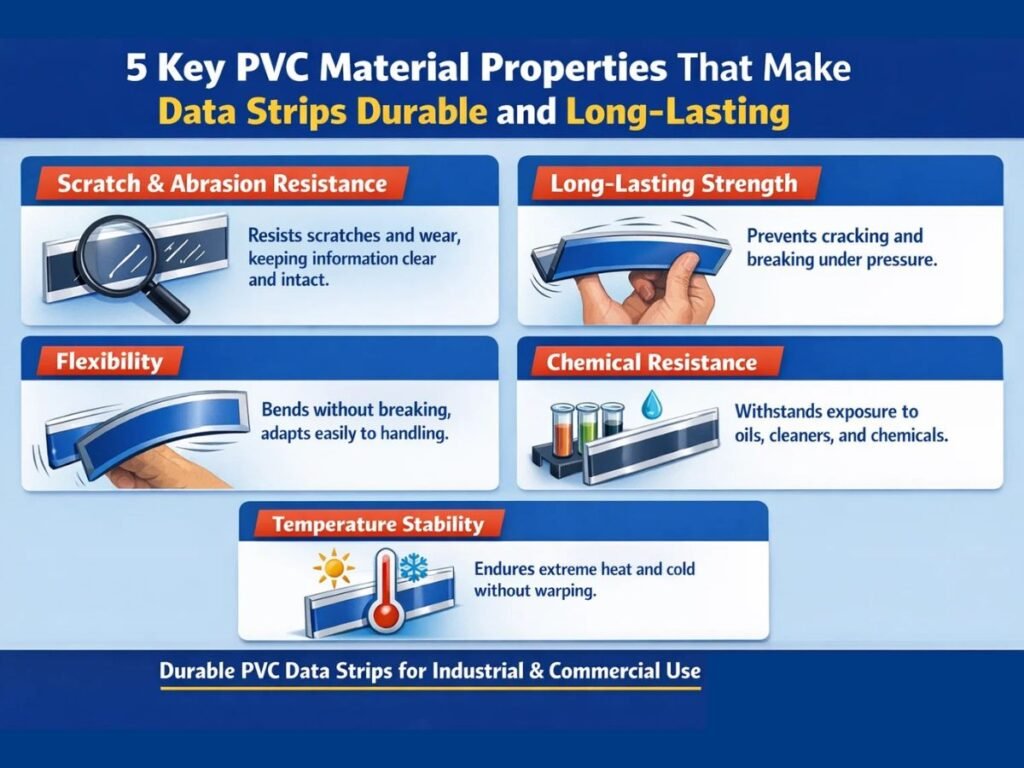

5 Key PVC Material Properties That Make Data Strips Durable and Long-Lasting

PVC forms the backbone of data strips, providing the toughness and resilience they need to last. Its natural strength allows the industrial PVC data strips to withstand daily handling, bending, and pressure without cracking or breaking. At the same time,

PVC remains flexible enough to adapt to industrial processes like extrusion, molding, and finishing, ensuring that every strip meets consistent quality standards.

The material also resists scratches, minor impacts, and chemical exposure, keeping the surface smooth and the information on the strip readable over time. PVC performs reliably under changing temperatures and environmental conditions, which is essential for industrial applications. Its ability to maintain shape and function even with heavy use makes it a preferred choice for offices, warehouses, manufacturing units, and logistics operations.

Combined with careful production techniques, PVC ensures that data strips remain durable, functional, and long-lasting, providing industries with reliable tools for identification, tracking, and data management.

Here are five key PVC material properties that make data strips durable and long-lasting.

Scratch and Abrasion Resistance

Due to its strong and resistant composition, PVC protects data strips from scratches and wear, keeping information visible as well as reliable. This ensures the data strips stay functional and intact even with regular handling in industrial environments.

- Protects information: PVC prevents surface damage that could obscure or erase printed or engraved data, keeping labels and identification readable over time.

- Keeps surfaces smooth: By resisting scratches and abrasion, PVC helps data strips slide easily through machines, scanners, or holders without getting stuck or damaged.

- Maintains usability: The scratch-resistant surface keeps data strips smooth and easy to handle, reducing errors during scanning, reading, or installation.

By providing scratch and abrasion resistance, PVC ensures data strips remain long-lasting, readable, and dependable, making them ideal for industrial and high-usage applications.

Long-Lasting Strength

In addition to making the surface resistant to scratches and abrasion, PVC also provides the toughness needed to prevent bending, cracking, or breaking, ensuring data strips remain reliable over time.

- Prevents breakage: Because of PVC’s inherent strength, data strips resist cracking or bending, even under repeated handling or mechanical stress.

- Supports repeated use: By maintaining structural integrity, PVC allows data strips to withstand daily industrial operations without losing functionality.

- Ensures reliability: PVC’s durability helps strips perform consistently in scanners, holders, and other equipment, reducing downtime or errors in industrial workflows.

With its combination of toughness and resilience, PVC ensures data strips maintain consistent performance and usability, even in demanding industrial and high-traffic environments.

Flexibility

PVC’s flexible composition allows data strips to bend, twist and adapt without cracking or breaking, making them easier to handle and more durable in industrial applications.

- Prevents damage during handling: By absorbing force from twisting or bending, PVC strips resist structural damage and remain reliable.

- Supports repeated use: PVC’s elasticity ensures the data strips maintain their shape as well as functionality even after frequent handling or scanning.

- Maintains readability: Because PVC bends without warping, flexible strips keep printed or engraved information clear and legible, even after repeated handling or industrial use.

By combining strength with flexibility, PVC ensures that data strips remain resilient, adaptable, and reliable for long-term industrial use.

Chemical Resistance

With its ability to resist industrial chemicals, PVC makes data strips strong, reliable, and long-lasting, even when exposed to cleaning agents, oils or other substances. This chemical resistance prevents surface weakening and maintains the strip’s performance over time.

- Prevents surface degradation: By resisting chemical exposure, PVC strips retain their shape as well as surface integrity, avoiding damage or discoloration.

- Supports long-term use: PVC ensures strips perform consistently in high-traffic or industrial environments despite repeated chemical contact.

- Maintains functionality: Due to its chemical-resistant properties, PVC keeps printed or engraved information clear and ensures smooth operation in scanners, holders, and other equipment.

PVC’s chemical-resistant properties keep data strips durable and reliable, ensuring consistent performance in demanding industrial and high-use environments.

Temperature Stability

No matter whether the temperature is hot or cold, PVC protects data strips from warping, cracking, or losing performance. This ability ensures strips remain reliable and functional in all industrial conditions, regardless of environmental changes.

- Prevents warping or cracking: PVC maintains structural integrity under extreme temperatures, keeping data strips from bending, shrinking, or breaking during use.

- Supports long-term use: Since PVC withstands extreme heat and cold, data strips retain their performance and reliability even in harsh or changing industrial environments.

- Maintains readability: PVC preserves the clarity of printed or engraved information, even when exposed to heat, cold or temperature changes over time.

PVC’s resistance to extreme temperatures keeps data strips durable, reliable and fully functional for long-term use in industrial applications.

Conclusion

The inherent properties of PVC ensure that data strips continue to perform effectively over time. Durable, reliable and resistant to everyday wear and environmental challenges, these strips maintain their shape, readability and functionality even under frequent handling.

Industries benefit from this consistency, as it reduces the need for replacements and minimizes errors during operations.

Well-suited for high-use and demanding environments, PVC data strips in India deliver long-term performance and dependable results. Their design as well as material composition make them a practical, efficient and trustworthy solution for maintaining smooth workflows and operational reliability.

Are you looking for durable PVC data strip profiles for commercial and industrial applications? M3 Extrusion offers high-quality PVC data strip profiles that are durable and built to last.

Frequently Asked Questions

How does the flexibility of PVC improve the durability of data strips?

The flexibility of PVC allows data strips to bend, twist, or adapt without cracking or breaking. This property prevents damage during handling or installation while keeping the strip’s shape intact and ensuring that printed or engraved information remains clear and readable over time.

Why is PVC preferred over other plastics for data strips?

PVC combines strength, flexibility, chemical resistance, and environmental stability in one material. These combined properties make it more reliable and durable than many other plastics for industrial and long-term use.

How does PVC’s resistance to water protect data strips?

PVC does not absorb water, which prevents warping, swelling or damage from moisture. This makes data strips suitable for humid environments or areas where accidental spills may occur, keeping them functional for longer periods.

How does PVC affect the weight and handling of data strips?

PVC is lightweight yet sturdy, making data strips easy to handle, transport and store. Its balance of weight and strength ensures convenience without compromising durability.

How does PVC improve the resistance of data strips to physical impacts?

PVC’s toughness absorbs minor impacts and pressure, preventing cracks, bends, or breaks. This property ensures that the strips remain intact even in demanding industrial or office environments.

Check related articles for more insights: