Choosing the right material is one of the most important decisions in manufacturing and product design. The wrong choice can lead to frequent breakage, wasted resources, and higher costs. Traditional options like glass and metals may offer durability, but they also bring drawbacks such as weight, fragility, or expense.

This is why high-impact polystyrene plastic in India has become a practical solution. Known as HIPS, this material is valued for its toughness, lightweight properties, and cost-effectiveness. It helps industries reduce breakage, minimise waste, and achieve greater efficiency across applications.

What is High Impact Polystyrene (HIPS)?

High impact polystyrene is a type of thermoplastic that combines rigidity with impact resistance. It is created by blending polystyrene with rubber, making it less brittle and more resistant to cracking under stress.

Key characteristics include:

- Lightweight and strong, ideal for applications where reducing weight is important

- Impact resistant, less prone to damage during production, handling or shipping

- Easy to process, suitable for extrusion, thermoforming and fabrication

- Affordable, often costing less than many metals or engineered plastics

Because of these qualities, HIPS is now used across packaging, retail, automotive, consumer electronics and even medical industries.

How Breakage Affects Businesses

Breakage may seem like a minor issue, but it creates major losses over time. If a component cracks during manufacturing or a product breaks during transport, companies lose not only the material but also labour and time. Replacements, rework and dissatisfied customers all increase expenses.

Examples of common breakage issues:

- Glass packaging shattering during shipping

- Thin plastics snapping during assembly

- Heavy metal parts bending or warping under strain

HIPS provides a solution by absorbing shocks and resisting cracking, reducing these common problems.

How HIPS Reduces Waste

One of the hidden benefits of high impact polystyrene is its ability to cut waste during both manufacturing and product use.

- During production: It processes cleanly with fewer rejects or defective parts

- During transport: Its strength reduces the risk of breakage, meaning fewer damaged goods

- After use: HIPS can be recycled, lowering the overall environmental footprint

This makes it a smart choice for businesses aiming to balance performance, cost and sustainability.

Lightweight Alternative to Heavy Materials

Many industries have traditionally depended on metals for durability. However, metals often bring challenges such as high weight, costly raw material prices and difficult handling. Similarly, glass may look attractive but is fragile and increases shipping risks.

For these reasons, businesses are now exploring lightweight plastic alternatives to heavy and costly metals. High impact polystyrene fits this requirement well, offering reliability without unnecessary weight or expense. This makes it a go-to material for products where both performance and cost-efficiency matter.

Key Applications of HIPS

The versatility of HIPS is one of the main reasons behind its growing use. Let’s look at how it supports different industries:

1. Packaging Industry

From food trays to protective casings, packaging requires durability and hygiene. HIPS is impact resistant, easy to shape and safe for many consumer uses. It reduces the risk of damaged packaging during shipment, saving companies both money and reputation.

2. Retail Displays and Signage

Retail spaces rely on visual appeal. HIPS provides the glossy finish and printability needed for displays, boards and signage. Unlike fragile materials, it resists cracking even with frequent handling.

3. Electronics

Gadgets and appliances need strong casings that protect internal components without adding weight. HIPS is commonly used in television housings, computer parts and small electronic devices.

4. Automotive Interiors

Car interiors require lightweight materials that do not compromise on safety. HIPS provides panels, trims and components that maintain strength while keeping vehicles lighter and more fuel-efficient.

5. Medical and Laboratory Use

HIPS is also valued in the medical industry for disposable items like test trays and equipment housings. Its easy moulding and hygienic qualities make it reliable in sensitive environments.

Cost Efficiency Over Time

While metals or high-grade engineered plastics may seem attractive, they often come with high costs and processing difficulties. By comparison, HIPS offers:

- Lower raw material cost

- Reduced production waste

- Less damage during shipping and storage

- Recyclability for eco-conscious businesses

The result is long-term savings and a more efficient manufacturing cycle. Companies that adopt HIPS often find that the material pays for itself by reducing hidden costs like product returns, warranty claims and material wastage.

Why Indian Industries Are Adopting HIPS

India’s industries are diverse, covering packaging, retail, automotive, consumer goods and electronics. In all these sectors, businesses need materials that are reliable, cost-effective and adaptable to both small and large-scale production.

HIPS offers this flexibility. It can be customised to suit different designs, maintains consistency in quality and helps manufacturers meet both local and international standards.

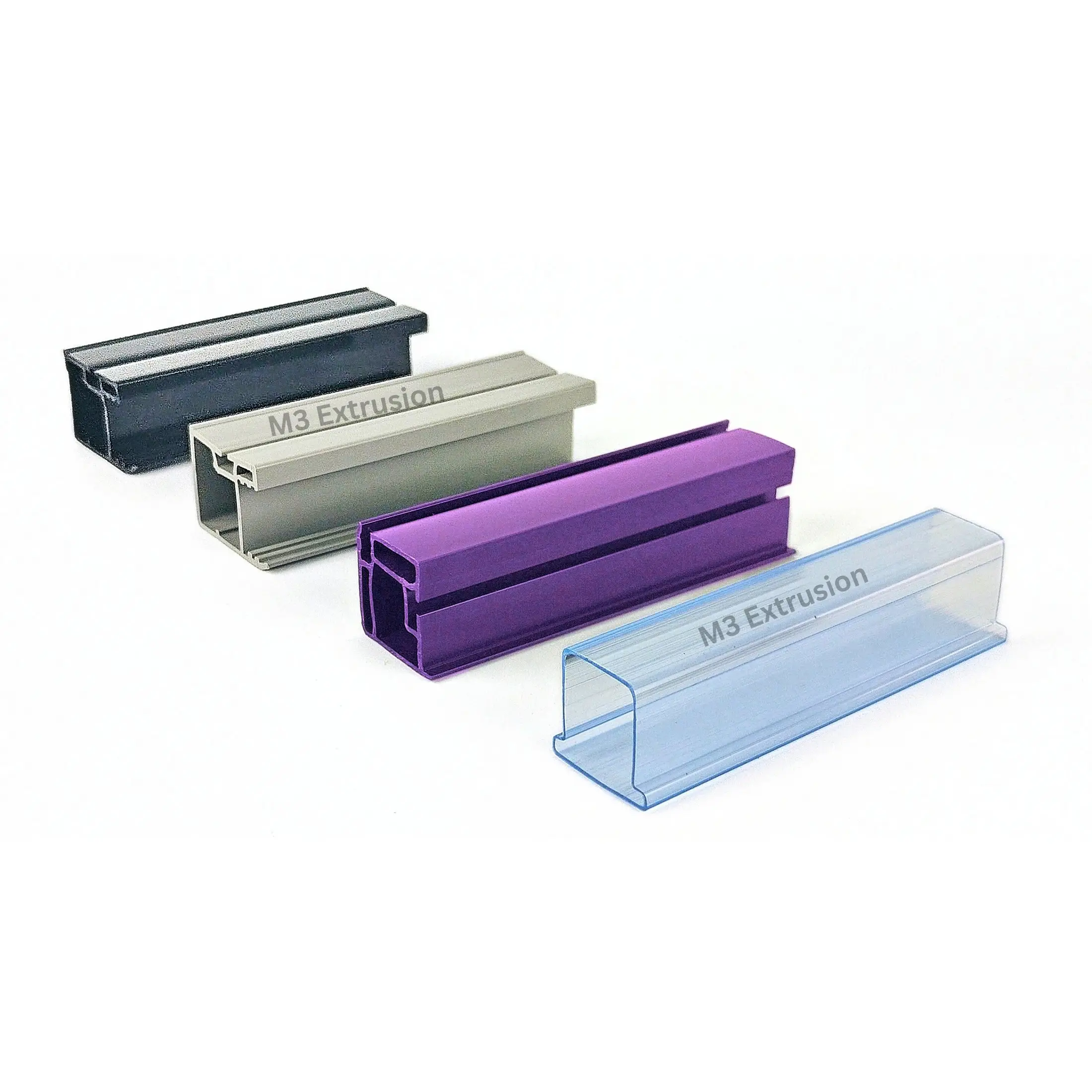

Brands like M3 Extrusion are supporting this demand by providing quality extruded plastic profiles, ensuring businesses in India get durable and cost-effective solutions that reduce waste and improve performance.

FAQs on High-Impact Polystyrene Plastic

Q1. What makes HIPS better than regular polystyrene?

Unlike regular polystyrene, which is brittle, HIPS is modified with rubber particles, giving it superior toughness and impact resistance.

Q2. Can HIPS be used outdoors?

It is better suited for indoor use unless stabilised with additives, as prolonged UV exposure may cause degradation.

Q3. How does HIPS reduce costs in the long term?

Its strength reduces breakage, its consistency lowers defects in production, and recyclability helps cut raw material expenses.

Q4. Is HIPS a complete replacement for metals?

Not always, but in many applications where weight, cost and breakage are concerns, HIPS serves as a reliable alternative.

Q5. Where is HIPS most widely used in India?

It is widely applied in packaging, retail displays, electronics housings and automotive interiors.

Conclusion

High impact polystyrene plastic is more than a convenient material. It is a problem-solving solution for modern industries. By reducing breakage, cutting waste and providing a lightweight yet strong option, it addresses many of the challenges faced in manufacturing and transport.

For businesses in India aiming to stay competitive while controlling costs, HIPS provides a balance that traditional materials like metals and glass often cannot achieve. Choosing this material is not just about performance, it is about creating long-term efficiency and sustainability.