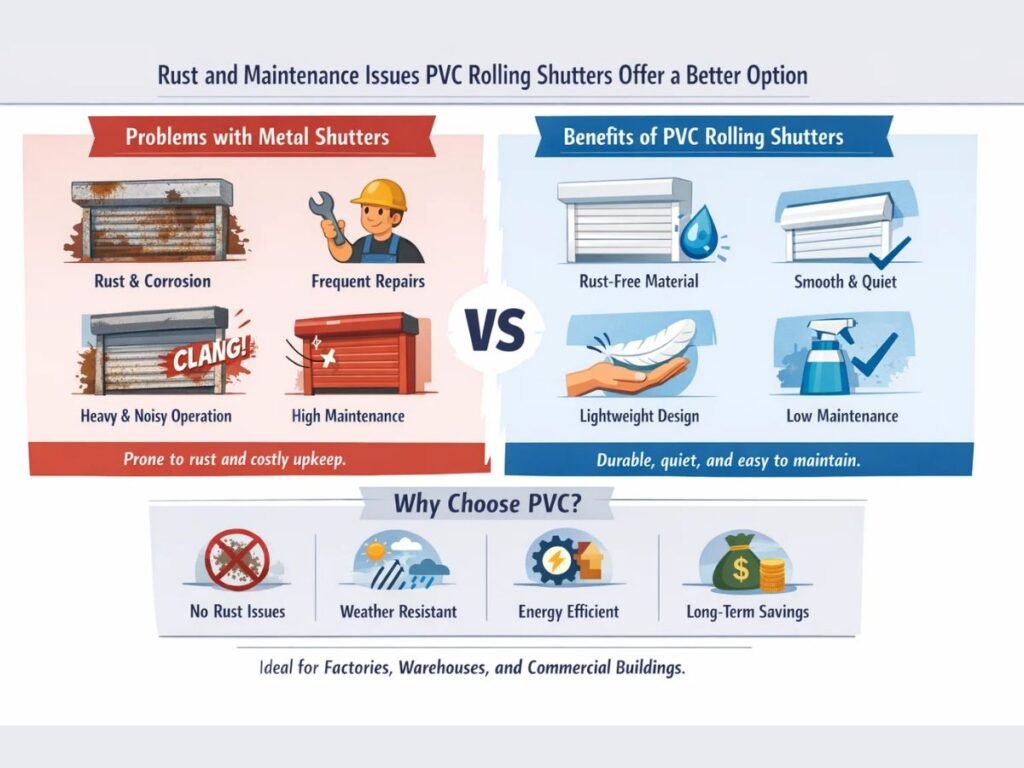

If you manage an industrial building or commercial property, you have likely dealt with rusted shutters, jammed mechanisms, and frequent maintenance calls. Traditional metal shutters often look strong at first, but over time, moisture, dust, and daily use take their toll. This is where a PVC rolling shutter for windows starts to make practical sense, especially in Indian weather conditions.

Across factories, warehouses, and commercial facilities, many buyers now choose a PVC rolling shutter in India to reduce long-term issues linked to corrosion, heavy weight, and ongoing repairs.

Why Rust Is a Common Problem with Conventional Shutters

Steel and iron shutters are widely used, but they come with a known drawback: rust. In coastal areas, industrial zones, and regions with high humidity, corrosion can start within a short period.

Common issues include:

- Surface rust that spreads into joints and slats

- Stiff operation due to corroded guides

- Increased load on motors and manual mechanisms

- Frequent repainting and part replacement

Over time, rust does more than affect appearance. It weakens shutter strength and increases safety risks, especially for windows that are opened and closed daily.

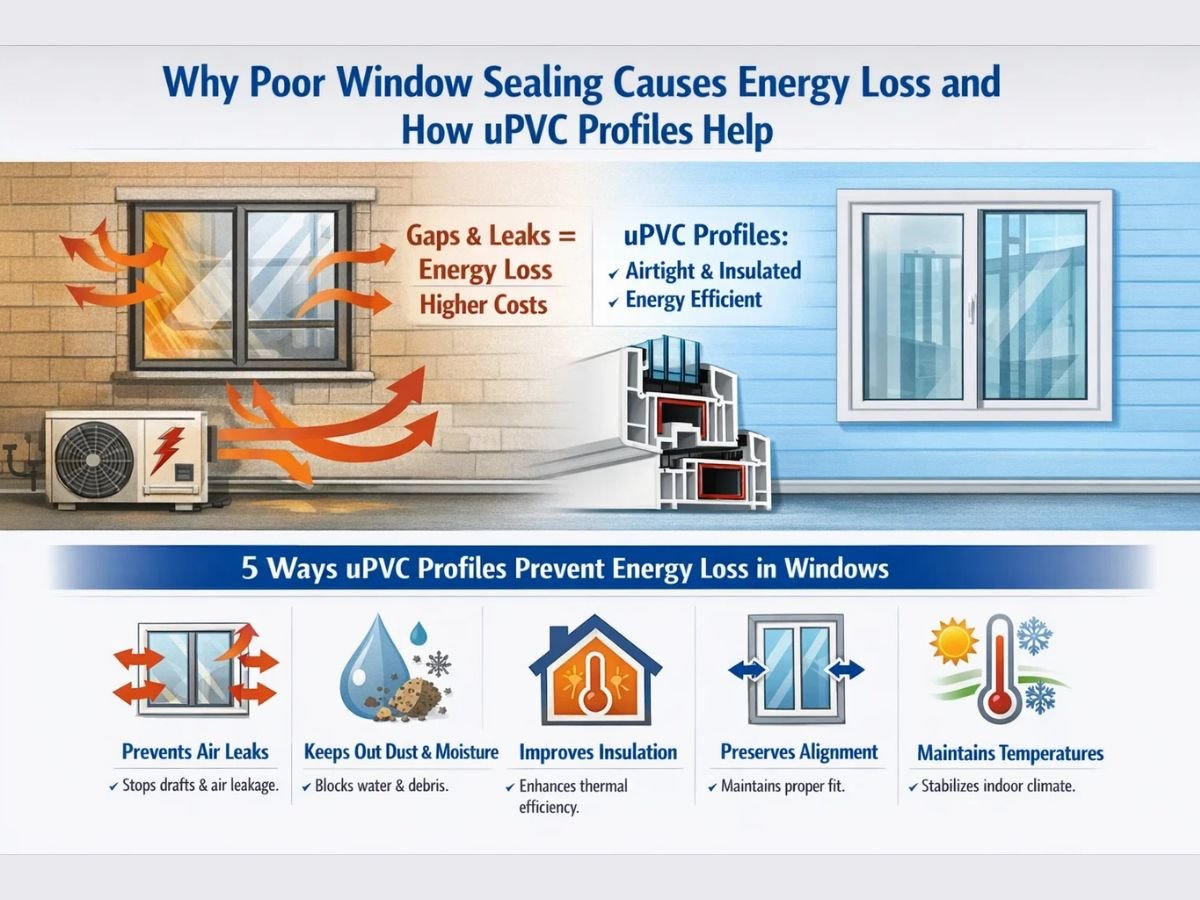

How PVC Rolling Shutters Solve Rust-Related Issues

A PVC rolling shutter for windows is manufactured using polyvinyl chloride, a material that does not corrode when exposed to moisture or air. Unlike metal, PVC does not react with water or humidity.

Key advantages include:

- No rust formation, even in damp environments

- Smooth operation over long periods

- Stable appearance without repainting

- Lower risk of parts seizing or jamming

For industrial users, this means fewer breakdowns and more predictable operation.

Lower Maintenance Needs in Daily Use

One of the main reasons businesses shift to a PVC rolling shutter in India is reduced maintenance. Metal shutters require regular lubrication, rust treatment, and repainting. PVC shutters, on the other hand, are far simpler to maintain.

What routine care looks like

- Occasional cleaning with water or mild detergent

- Basic inspection of guides and rollers

- No need for anti-rust coatings

This makes PVC rolling shutters suitable for facilities where downtime must be kept to a minimum.

Weight Matters More Than You Think

Metal shutters are heavy. Over time, this weight affects:

- Window frames

- Hinges and guide rails

- Manual handling effort

- Motor lifespan in automated systems

PVC rolling shutters are much lighter, which reduces stress on supporting structures. For window installations, especially in commercial buildings, this lighter load helps maintain alignment and smooth movement.

Weather-Resistant PVC Rolling Shutters in Real Conditions

Indian weather can be demanding, with heat, rain, dust, and pollution affecting building components. Weather-resistant PVC rolling shutters are designed to handle these conditions without degrading quickly.

They perform well in:

- High-humidity industrial zones

- Areas with frequent rainfall

- Locations exposed to dust and airborne particles

- Sun-exposed façades where heat build-up is common

PVC does not swell, rust, or flake, helping shutters retain their shape and function across seasons.

Better Fit for Industrial and Commercial Windows

PVC rolling shutters are widely used for:

- Factory window openings

- Warehouse ventilation windows

- Service area windows

- Commercial building façades

Because PVC profiles can be extruded to precise dimensions, shutters fit windows accurately. This improves sealing, reduces rattling noise, and supports smoother operation during daily use.

Noise and Operational Comfort

Metal shutters often create noise during opening and closing, especially once wear sets in. PVC rolling shutters operate more quietly, which is useful in:

- Production areas

- Commercial spaces

- Facilities running multiple shifts

Reduced noise improves working conditions without compromising security.

Long-Term Cost Comparison

While the initial cost of shutters is important, long-term expenses often matter more. When you compare metal and PVC options over time, the difference becomes clear.

Factor | Metal Shutter | PVC Rolling Shutter |

Rust risk | High | None |

Maintenance frequency | High | Low |

Repainting | Required | Not needed |

Weight impact | Heavy | Lightweight |

Operational life | Reduced by corrosion | Stable over time |

For many buyers, this makes a PVC rolling shutter in India a more economical choice in the long run.

A Practical Example from Industrial Use

A warehouse in a high-humidity zone initially installed metal shutters for its window openings. Within two years, rust led to frequent jamming and repainting. After switching to PVC rolling shutters, maintenance calls dropped sharply, and daily operation became smoother.

This type of experience is common in facilities that move away from metal shutters.

Choosing the Right PVC Rolling Shutter Supplier

Quality matters when selecting PVC rolling shutters. Profile strength, dimensional consistency, and material formulation all affect performance. Manufacturers like M3 Extrusion produce PVC rolling shutter profiles designed for industrial use, focusing on consistent extrusion and long-term reliability.

The right supplier ensures:

- Stable material quality

- Accurate profile dimensions

- Suitability for repeated production orders

Key Takeaways

- Rust is a major weakness of metal shutters

- PVC rolling shutters do not corrode or flake

- Maintenance requirements are much lower

- Lightweight construction protects window structures

- Weather-resistant PVC rolling shutters suit Indian conditions

For window applications in industrial and commercial buildings, PVC offers a practical balance of durability and ease of use.

Frequently Asked Questions

Are PVC rolling shutters suitable for window installations?

Yes. PVC rolling shutters are widely used for windows in factories, warehouses, and commercial buildings. Their lightweight structure and precise fit make them easy to operate while maintaining security and consistent performance over daily use.

Do PVC rolling shutters rust over time?

No. PVC material does not react with moisture or air, so rust does not form. This makes PVC rolling shutters ideal for humid, rainy, or coastal environments where metal shutters often corrode.

How long do PVC rolling shutters last?

With proper installation and basic cleaning, PVC rolling shutters can last many years. Since they are not affected by rust or corrosion, their operational life is often longer than metal shutters in similar conditions.

Are PVC rolling shutters weather resistant?

Yes. Weather-resistant PVC rolling shutters handle rain, heat, dust, and humidity well. They retain their shape and function across seasonal changes, making them suitable for Indian climate conditions.

Do PVC rolling shutters need frequent maintenance?

No. Maintenance is minimal and usually limited to cleaning and basic inspection. Unlike metal shutters, PVC shutters do not need repainting or anti-rust treatment.

Can PVC rolling shutters be used with automation systems?

Yes. Their lightweight design makes them suitable for both manual and motorised systems. Reduced load helps motors operate efficiently and extends their service life.

Are PVC rolling shutters safe for daily industrial use?

Yes. They are designed for repeated opening and closing, offering smooth operation, consistent alignment, and dependable performance in daily industrial and commercial environments.

Check related articles for more insights:

- A Complete Guide to Choosing the Best Rolling Shutter PVC for Your Facility

- Practical Benefits of Using PVC Rolling Shutters in Commercial Buildings

- How PVC Rolling Shutters Address Space and Installation Challenges in US Industries

- Tired of Heavy, Rusting Shutters? PVC Rolling Shutters Offer a Cleaner, Easier Solution for Commercial Projects in the USA