Solving Diffusion and Strength Challenges with polycarbonate transparent profile

Ever wondered how modern buildings and factories achieve clear views without losing durability? The answer often lies in a material you may not expect — the polycarbonate transparent profile.

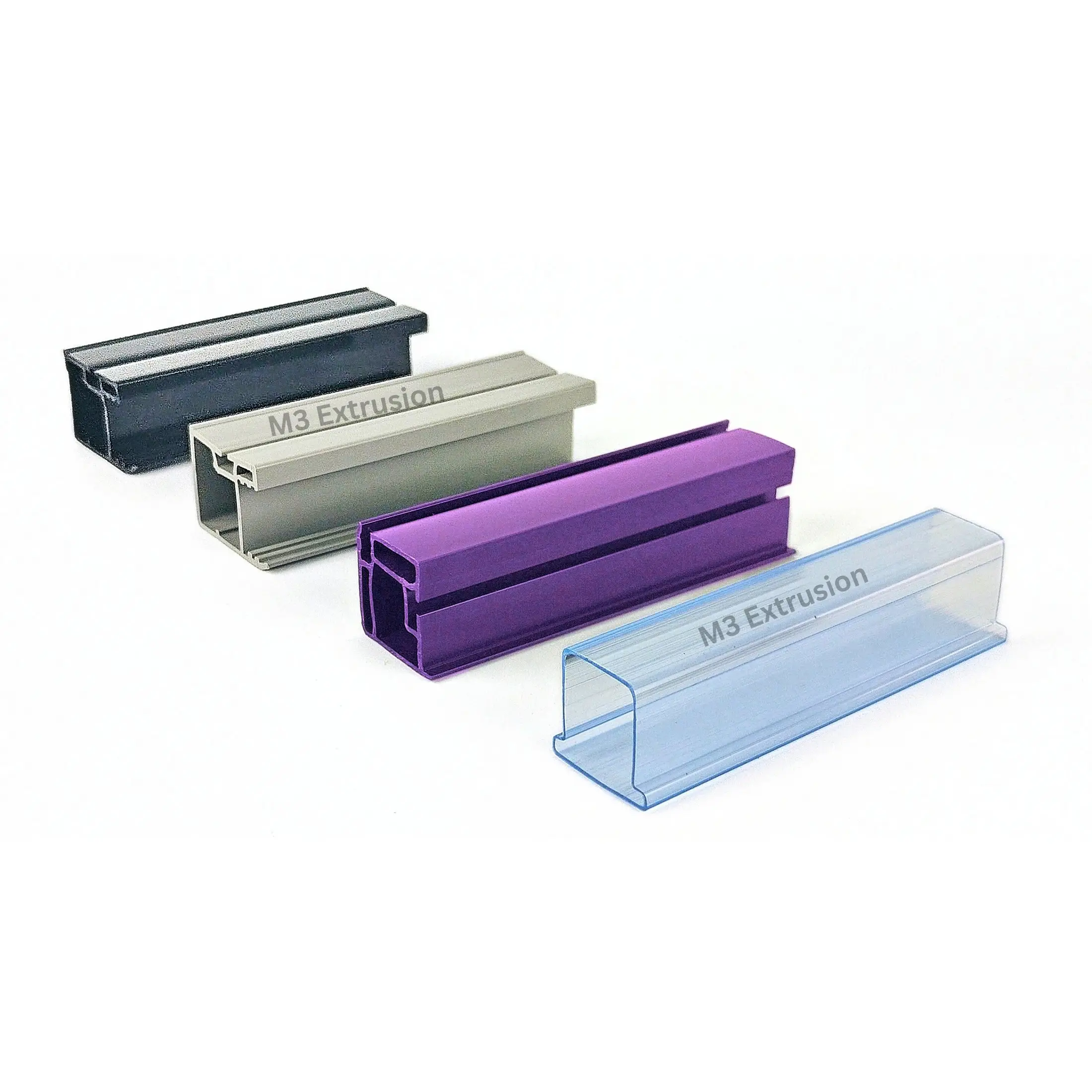

At M3 Extrusion, we know industries need more than simple clarity. They need toughness, impact resistance, UV defence and even light diffusion — all from one product. Our skill in crafting precise, clear polycarbonate profiles means your projects stay strong and look great for years.

Why Diffusion and Strength Matter More Than Ever

In fields where performance counts as much as appearance, clear plastics must do more than shine. They must withstand weather, absorb shocks, and spread light evenly without yellowing or cracking.

M3 Extrusion meets these needs by using top-quality materials and advanced extrusion methods. Our polycarbonate transparent profile in India delivers superior strength and excellent light diffusion, making it perfect for many uses.

The Science Behind Polycarbonate Transparent Profiles

Polycarbonate is a type of plastic celebrated for:

- High Impact Resistance — around 200 times stronger than glass.

- UV Stability — does not turn yellow in sunlight.

- Exceptional Light Transmission — up to 90% clear.

- Thermal Endurance — stays shape in very hot or cold conditions.

At M3 Extrusion, our tailored, clear polycarbonate profiles go through strict quality checks to ensure they achieve top marks in both strength and light diffusion.

Where Challenges Typically Arise

Even with many benefits, problems can appear without proper production skills:

- Poor Light Diffusion: Uneven glow in LED lights or signs

- Structural Weakness: Cracks or bends under stress

- Weather Damage: Loss of clarity and becoming brittle after sun exposure

M3 Extrusion solves these issues by adjusting polymer mixes, refining extrusion settings, and using special surface treatments. The result is a dependable polycarbonate transparent profile in India every time.

How M3 Extrusion Solves These Problems

At M3 Extrusion, we handle every project with precise engineering and care:

Tailored Material Formulations

We fine-tune the resin’s additives to give the right mix of light diffusion, UV protection and impact strength for your needs.

Advanced Extrusion Technologies

With twelve extrusion lines, we make clear polycarbonate profiles that have smooth surfaces and exact dimensions every time.

Customised Profile Design

From basic tubes to intricate co-extruded shapes, we craft designs that match your project’s exact needs.

In-House Tooling and die-making

Our own die-making workshop lets us work faster and keep full control over quality at each step.

When you choose M3 Extrusion, you’re getting more than a profile — you’re getting a solution built for performance.

Applications Where Performance Matters Most

The versatility of the Polycarbonate Transparent Profile has led to its use in many industries, including:

- LED Lighting Fixtures: Even glow without bright spots

- Greenhouses: Lets in maximum sunlight while staying strong

- Protective Screens: Tough, lightweight barriers

- Signage: Clear, weatherproof outdoor signs

- Architectural Features: Transparent elements with visual appeal

In every case, M3 Extrusion makes sure your profiles meet both practical and aesthetic needs.

Polycarbonate Transparent Profile: Rising Demand and Why M3 Extrusion Leads

If you need a high-performance polycarbonate transparent profile in India, M3 Extrusion is the answer. The Indian market is seeing growing demand for plastic solutions that resist harsh conditions and still look good. Our modern plant in Gujarat lets us serve both local and overseas customers with speed, quality, and flexibility.

Whether your order is 100 metres or 10,000 metres, M3 Extrusion delivers top-quality profiles every time.

Why Choose M3 Extrusion for Your Polycarbonate Needs?

Picking the right supplier affects how long your product lasts, how well it works, and your overall value. Here’s what makes M3 Extrusion different:

- Over 13 Years of Industry Experience

- Custom Solutions Designed for Your Application

- Strict Quality Control and Compliance

- In-House Rapid Prototyping Capabilities

- On-Time Delivery and Worldwide Shipping

Find the Perfect Polycarbonate Transparent Profile for Your Project

Strength without clarity is pointless, and clarity without strength is risky. At M3 Extrusion, our Polycarbonate Transparent Profile in India delivers both, solving the light diffusion and durability challenges of modern industries. Rely on us to bring your ideas to life with materials made to last, impress, and perform.

FAQs

Q1: What is the typical lifespan of a clear polycarbonate profile?

With correct fitting, profiles from trusted makers can last more than 10 years, even outdoors.

Q2: Can polycarbonate profiles be customised in terms of colour and diffusion?

Yes. You can choose different colours, levels of clarity and light diffusion, and even surface finishes.

Q3: Are polycarbonate profiles better than acrylic for outdoor use?

Yes. Polycarbonate Transparent Profile is much tougher and resists UV damage far better than acrylic.

Q4: How do I ensure proper maintenance of polycarbonate profiles?

Clean them regularly with mild soap and water. Don’t use rough cloths or abrasive cleaners to keep them clear and strong.

Q5: Can polycarbonate transparent profiles handle extreme temperatures?

Yes. They tolerate temperatures from –40 °C up to 120 °C without losing performance.