Want to make your manufacturing process more efficient and eco-friendly? It starts with smarter design, especially when it comes to plastic co-extrusion. If you’re in industries like construction, refrigeration, automotive, or electrical, you already know how important precision is. But did you know that with the right co-extrusion design, you can dramatically reduce material loss, energy use, and unnecessary costs?

At M3 EXTRUSION, we specialise in helping manufacturers optimize their profiles for function, durability, and sustainability—all while keeping waste to a minimum.

What is Plastic Co-Extrusion Anyway?

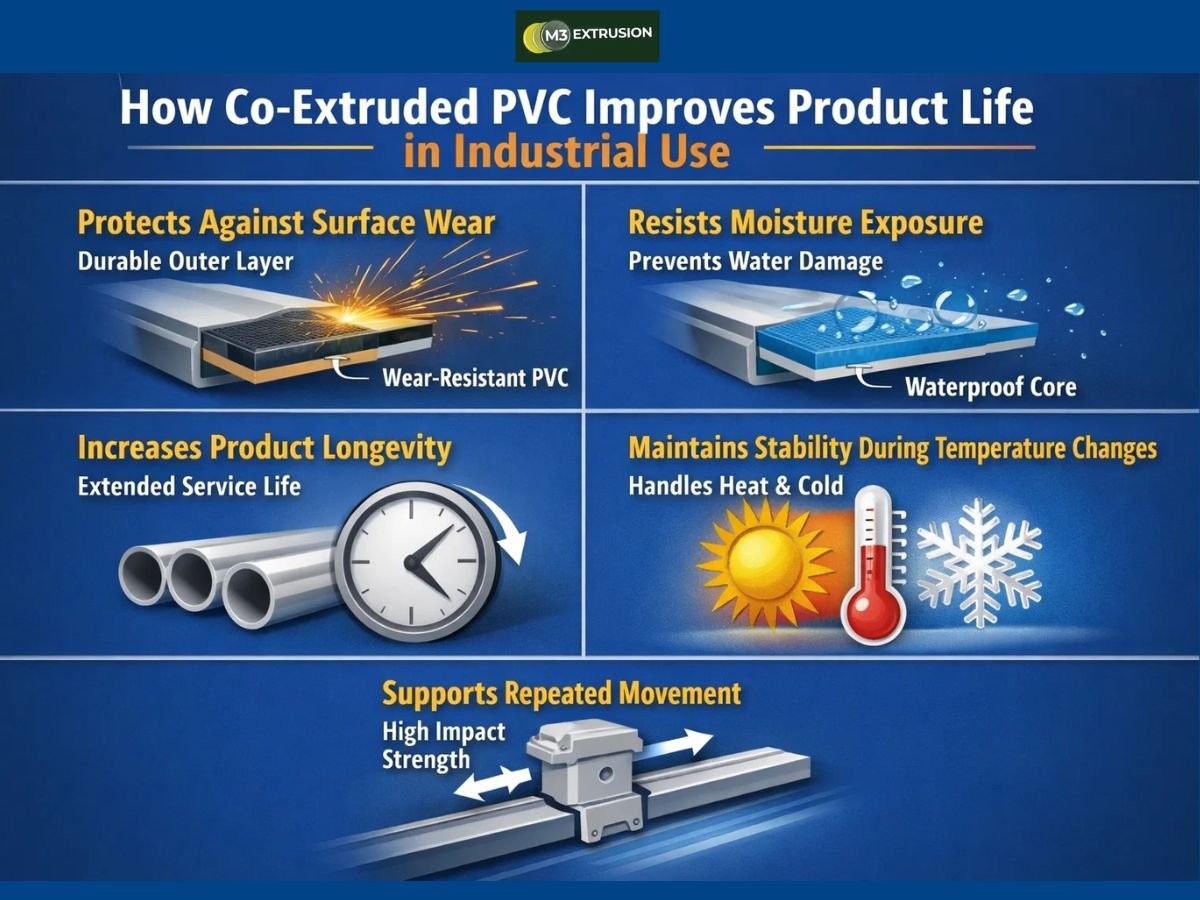

Plastic co extrusion is a process where two or more different materials are pushed through a die at the same time to create a single profile with multiple layers. Think of it like a layered cake — each layer has a different role, but together, they form something solid, strong, and useful.

This technique is being used to develop cutting-edge, custom profiles that reduce waste and enhance product performance for industries not only in India but globally.

How Plastic Co Extrusion Helps Cut Down Waste

If you’re wondering how plastic co extrusion in India is turning heads in the sustainability world.

1. Material Optimization

By blending materials strategically, you only use what’s necessary. For instance, a soft inner core and a tough outer shell make use of cheaper or recycled materials in non-visible areas — saving on raw costs and resources.

2. Fewer Production Errors

Accurate design means less trial and error. When profiles are built to spec from the start, you avoid costly re-runs and material scrapping. That’s a win for both time and the environment.

3. Multi-Functionality in One Go

With plastic co extrusion, there’s no need to manufacture multiple parts and assemble them later. One streamlined part = fewer machines, fewer processes, and definitely less waste.

4. Reusable Trims and Scraps

Excess trimmings from co-extruded products are often easier to recycle because the material combinations are planned in advance to be compatible. That’s smart sustainability in action.

Designing for Waste Reduction: What to Consider

Accurate design is the foundation. Here are a few best practices that M3 EXTRUSION follows when creating eco-conscious co-extruded plastic profiles:

- Start with the End in Mind: Think about where the product will be used, and choose materials accordingly — not every layer needs premium-grade plastic.

- Use Recycled Materials Where Possible: Strategic placement of recycled layers (like the core) helps reduce virgin material consumption.

- Minimize Trim Loss: Precise die-cutting and shape optimization ensure you’re not shaving off more than you should.

- Plan for Scalability: A design that works at a small volume but fails at high speed is wasteful. The goal is to get it right from prototype to production.

Industries Benefiting from Co-Extrusion Waste Reduction

Plastic co-extrusion isn’t just smart tech — it’s smart business. Industries across the board are seeing the advantages:

- Refrigeration: Gaskets and door seals built with dual hardness for insulation and flexibility — less scrap better performance.

- Construction: Durable corner guards and trims made from layered plastics reduce replacements and repairs.

- Electronics: Customized profiles that shield sensitive components without over-engineering.

- Healthcare: Hygienic wall guards and edge protectors are designed with precise materials for safety and reusability.

Why Choose M3 EXTRUSION for Plastic Co-Extrusion in India?

For over 13 years, M3 EXTRUSION has delivered high-quality, custom plastic profiles to global clients. Their expertise in plastic co extrusion in India allows them to create sustainable solutions without compromising on durability, finish, or function.

By using advanced extrusion lines and material science knowledge, they help brands streamline their designs, reduce production waste, and hit their performance goals.

Start Designing Smarter Today!

Waste reduction doesn’t require a massive overhaul — sometimes, it just needs smarter design. With plastic co extrusion, you’re not only enhancing product quality but also doing your bit for a cleaner planet and a leaner production process.

If you’re ready to reduce your production waste, streamline operations, and create custom profiles that work smarter, now’s the time to make the switch.

Connect with M3 EXTRUSION today and discover how their plastic co-extrusion solutions can elevate your manufacturing process.

FAQs About Plastic Co Extrusion

1. What’s the main benefit of plastic co extrusion?

The biggest advantage is the ability to combine different materials into one strong, functional profile—saving production time and reducing material waste.

2. Can co-extruded products be recycled?

Yes! If the materials are compatible or strategically placed, co-extruded products can be easier to recycle than assembled parts made from different materials.

3. Is plastic co extrusion expensive?

Not really. While it may require an initial investment in design and tooling, the long-term savings from material efficiency and reduced waste make it cost-effective.

4. What types of plastic can be co-extruded?

Materials like PVC, TPE, ABS, Polypropylene, and Polycarbonate are commonly used.

5. How long does it take to get a custom design ready?

That depends on complexity, but our team typically delivers design prototypes within a few weeks for approval and testing.