In large construction and infrastructure projects, especially in India’s varied climate, every component used in windows and doors must be reliable, functional, and durable. While uPVC profiles often take the spotlight, the seals used around these profiles are just as important.

High-quality uPVC window seals in India have a direct impact on long-term performance. When these seals are custom-extruded for a project, they offer better fit, function, and finish. This is especially important in bulk supply projects where consistency across thousands of units matters.

Understanding Custom-Extruded uPVC Seals

Custom-extruded seals are sealing strips manufactured based on a specific shape, size, or application requirement. They are typically made from flexible materials such as EPDM, TPE, or silicone and are used in:

- Window and door frames

- Sliding and fixed partitions

- Curtain wall and glazing systems

- Weather-resistant sealing applications

The key difference between regular and custom-extruded seals is precision. While standard seals come in fixed profiles, custom seals are matched exactly to your system or drawing. This allows better integration with uPVC profiles and consistent sealing performance.

Why Customisation Is Critical for Large Projects

In high-volume window fabrication or installation projects, a mismatch in sealing size or shape can cause serious delays, poor performance, or client complaints. With custom-extruded seals, such issues can be avoided early.

Better Fit Means Better Performance

Custom seals align perfectly with the frame groove, ensuring tight contact with the glass and sash. This improves the seal’s ability to block air, water, and sound.

Project-Specific Solutions

Large uPVC projects vary from region to region. A housing project in Chennai will face humidity and coastal air, while one in Delhi deals with dust and dry heat. Custom seals allow the right material to be selected based on local conditions.

Reduced Installation Error

Standard seals often need trimming or force-fitting, which leads to inconsistent results. Custom profiles reduce these adjustments, making the installation faster and more uniform.

Improved Project Efficiency

By planning the sealing profile during the system design stage, developers and engineers avoid last-minute fitment issues, which helps in on-time project delivery.

Benefits of Custom-Extruded Seals in uPVC Projects

Here are some of the clear advantages these seals bring to large-scale building projects:

- Air-tight and water-tight protection, ideal for monsoon-prone or high-rise buildings

- Better energy performance by maintaining indoor comfort

- Improved acoustic insulation, especially in schools, hospitals, and offices

- Long-term durability with reduced shrinkage and ageing

- Clean and professional finish around windows and doors

Applications in Indian Industry

In India, large-scale construction projects span across different sectors. Custom-extruded seals are widely used in:

Commercial Real Estate

Office towers and IT parks use uPVC windows to reduce external noise and cut energy costs. Precision sealing ensures long-term performance and fewer maintenance complaints.

Residential Housing Projects

Multi-block apartment complexes require consistency. Custom seals reduce variation between units, improving overall build quality.

Hospitality Projects

Hotels need silent and leak-proof interiors. High-quality sealing plays a big part in achieving this standard.

Healthcare Facilities

In sensitive environments like hospitals and labs, proper air and moisture control is crucial. Well-designed seals support hygiene and safety.

Façade and Glazing Systems

Seals are essential in curtain walls and glazing systems to resist wind load, rain, and air pressure, especially in metro cities.

Choosing the Right Seal Material for Indian Conditions

Different regions in India experience different weather challenges—coastal humidity, urban dust, dry heat, and heavy rainfall. Selecting the right material is essential for lasting performance.

- EPDM Rubber – Strong, UV-resistant, and suitable for both heat and moisture

- TPE (Thermoplastic Elastomer) – Lightweight, cost-effective, and flexible

- Silicone Seals – Ideal for high-performance sealing and sensitive environments

- Wool Pile – Common in sliding systems, blocks dust and minor air leakage

Choosing the right material also depends on application type, installation method, and user preference.

Planning Ahead with Custom Seal Profiles

For large-scale uPVC projects, it’s best to plan the seal design at the system development stage. Providing accurate drawings or samples helps the extrusion company:

- Match the seal design exactly

- Choose suitable materials

- Produce consistent batches for mass production

- Ensure quality control during each run

This approach helps prevent supply gaps, installation delays, or product mismatches during the project.

To learn more about how sealing improves window durability in Indian homes, see:

Why uPVC Window Seals Matter for Long-Lasting Performance in Indian Homes

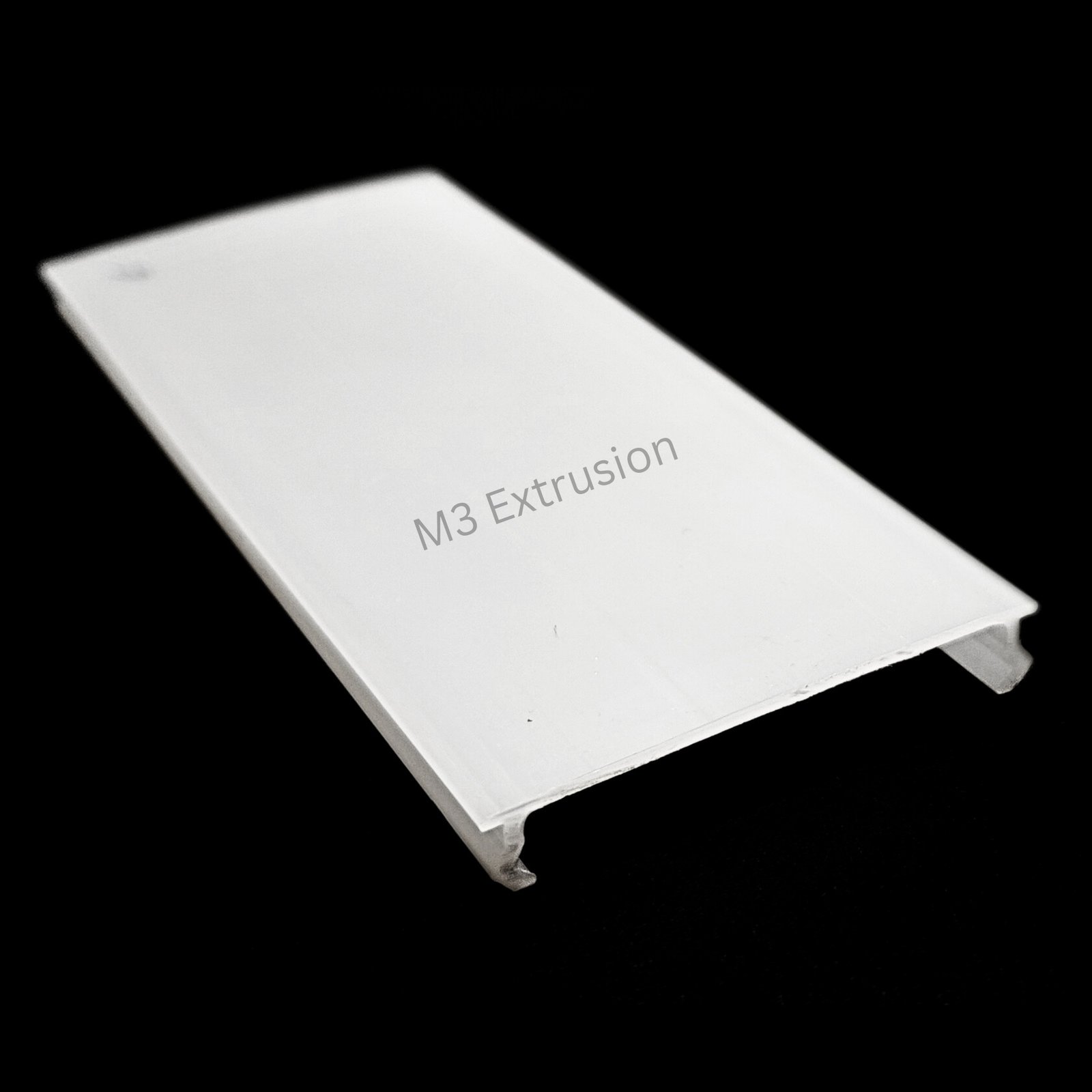

How M3 Extrusion Supports Large-Scale Sealing Requirements

M3 Extrusion supplies custom uPVC window seals in India, designed specifically for bulk projects in the construction, glazing, and fabrication industries. We produce sealing profiles based on your system design or sample, using materials tested for India’s climate conditions.

Our process supports real estate developers, commercial contractors, and window system manufacturers who need consistent quality, timely delivery, and flexibility for bulk supply.

Frequently Asked Questions (FAQ)

Q1. What’s the minimum order quantity for custom seals?

We mainly support bulk orders, but specific quantities depend on profile type and project needs.

Q2. Can I share my own profile drawing or sample?

Yes. We accept drawings, samples, or specifications and can match your seal design accordingly.

Q3. Do you deliver across India?

Yes. We deliver to all regions including metro cities, industrial zones, and project sites.

Q4. Are your seals suitable for high humidity or coastal areas?

Yes. Our seals are designed using materials suitable for different Indian weather conditions.

Q5. How long does it take to receive a custom seal order?

Timelines depend on profile type and quantity. We aim to support project schedules with timely production and dispatch.

Conclusion

In large uPVC projects, custom-extruded seals provide real benefits. They help reduce errors during installation, support energy savings, improve sealing performance, and ensure long-term durability across every window unit.

For Indian businesses and developers handling bulk requirements, using the right sealing partner ensures better project outcomes and fewer site issues.