Industries across India are increasingly adopting polycarbonate transparent profile in India for modern projects where durability and clarity are equally important. These profiles offer exceptional strength, impact resistance, and light transmission, making them suitable for both heavy-duty industrial use and high-precision architectural projects. Their adaptability has made them a reliable choice for businesses aiming to reduce costs, extend product life, and maintain quality.

What Makes Polycarbonate Transparent Profiles Unique?

Polycarbonate has distinct physical and chemical properties that set it apart from conventional materials like glass or acrylic. Its toughness is matched with clarity, making it suitable for projects that need both visibility and safety.

Key features include:

- High impact resistance – up to 250 times stronger than glass.

- Lightweight construction – reduces handling difficulties and transportation costs.

- Excellent light diffusion – maintains clarity without glare.

- Thermal stability – performs well in India’s hot and humid conditions.

- Shatter resistance – improves workplace safety and reduces replacement needs.

This combination of properties allows industries to meet modern project demands without compromising on safety or performance.

Industrial Applications of Polycarbonate Transparent Profiles

1. Construction and Architecture

Polycarbonate transparent profiles are widely used in roofing systems, skylights, cladding, and facades. They provide long-term durability while reducing reliance on artificial lighting. For example, a commercial complex in Pune installed skylight systems with polycarbonate profiles to cut electricity bills by 20%.

Practical benefits in construction include:

- Even distribution of natural light.

- Strong weather resistance in monsoon and summer.

- Easy installation compared to heavy glass panels.

2. Electrical and Electronics

In electrical panels and switchgear, polycarbonate profiles provide safe enclosures that protect delicate components. Their transparency allows technicians to check connections without opening covers, saving inspection time.

They are also non-conductive, making them ideal for use around high-voltage equipment. Many control panel manufacturers in India now prefer polycarbonate profiles for their combination of safety and practicality.

3. Retail and Display Fixtures

In retail environments, clear visibility and durability are key. Polycarbonate transparent profiles are used in shelving, signage, illuminated displays, and protective covers.

- They make displays attractive by allowing full product visibility.

- Their strength ensures they last longer even in busy, high-traffic stores.

- Profiles can be customised for branding and design purposes.

4. Automotive and Transport

The automotive industry values polycarbonate profiles for their balance of lightness and resilience. They are often used in:

- Interior trims.

- Headlamp covers.

- Ventilation channels.

By replacing heavier materials, they help reduce overall vehicle weight, improving fuel efficiency without sacrificing performance.

5. Industrial Machinery and Equipment

Safety shields and machine guards often require materials that are both clear and tough. Polycarbonate transparent profiles are an excellent fit. Operators can view ongoing processes while staying protected from flying debris, sparks, or moving components.

This not only enhances workplace safety but also reduces downtime caused by damaged covers or frequent replacements.

6. Greenhouses and Agricultural Structures

Agriculture in India increasingly relies on controlled environments. Greenhouses with polycarbonate transparent profiles ensure even light distribution, helping crops grow efficiently. Unlike glass, they resist breakage during storms, making them more reliable for long-term agricultural use.

Long-Term Benefits of Polycarbonate Transparent Profiles

Industries in India are moving toward polycarbonate transparent profiles because of their cost efficiency and durability. The advantages go beyond initial performance and extend into long-term benefits:

- Lower maintenance costs – Reduced breakage and repairs compared to glass or acrylic.

- Energy efficiency – Better natural lighting lowers electricity bills.

- Improved workplace safety – Shatterproof material protects workers and equipment.

- Design adaptability – Suitable for customised industrial and commercial requirements.

- Sustainability – Many polycarbonate products are recyclable, aligning with green building initiatives.

Industry Growth and Market Demand in India

India’s rapid infrastructure development, expansion of retail spaces, and modernisation of industrial facilities are fuelling demand for polycarbonate transparent profiles.

- The construction sector accounts for nearly 50% of the demand for polycarbonate applications in India.

- Electrical and electronic equipment manufacturers contribute significantly due to the growing emphasis on safe, reliable enclosures.

- The Indian retail market, one of the fastest-growing globally, is driving demand for durable display systems.

As industries push for smarter, safer, and more efficient solutions, polycarbonate transparent profiles are becoming an essential material choice.

Overcoming Diffusion and Strength Challenges

One of the biggest reasons industries choose polycarbonate over traditional materials is its ability to solve two common issues: diffusion of light and strength under stress. To see how these profiles address such challenges, you can read our detailed insight: Solving Diffusion and Strength Challenges with Polycarbonate Transparent Profiles.

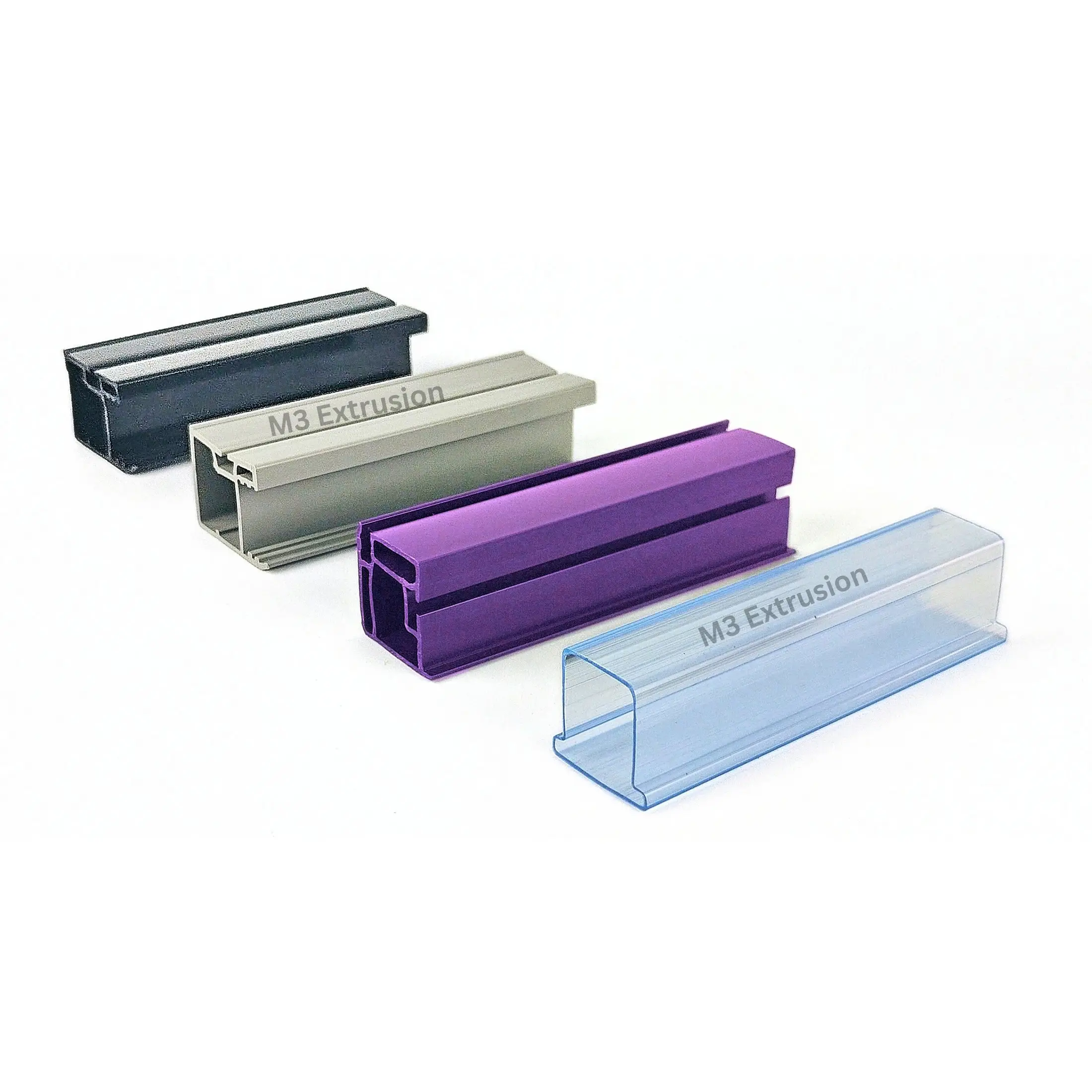

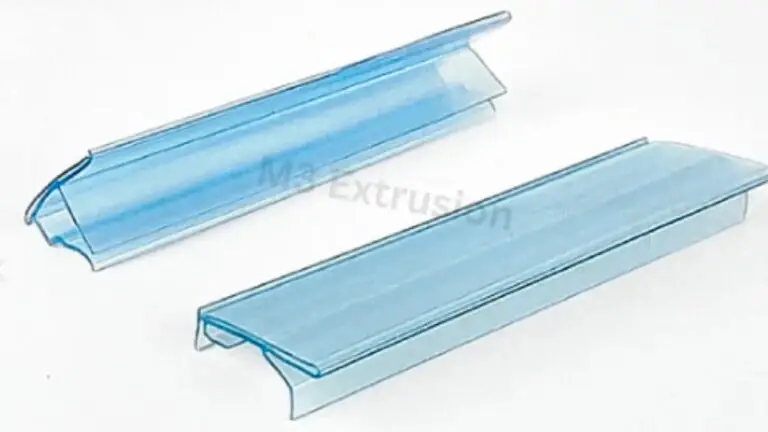

How M3 Extrusion Supports Industry Needs

At M3 Extrusion, we provide polycarbonate transparent profiles for industries in bulk, ensuring consistency and quality for every order. With a strong focus on B2B needs, our manufacturing capability supports large-scale projects in construction, retail, and industrial applications. By combining advanced extrusion technology with strict quality checks, we ensure businesses in India get reliable, long-lasting profiles suited to their requirements.

FAQs on Polycarbonate Transparent Profiles

Q1. What industries benefit most from polycarbonate transparent profiles?

Industries such as construction, retail, automotive, and electronics use these profiles widely. They provide durability, clarity, and long service life, which help reduce operating costs.

Q2. Are polycarbonate transparent profiles suitable for outdoor use?

Yes. They are designed to withstand India’s climate, including UV exposure, heat, and heavy rainfall. Their strength ensures long-term stability in outdoor projects like roofing and skylights.

Q3. How do polycarbonate profiles compare with glass in terms of cost?

While the upfront cost of polycarbonate may be slightly higher than glass, the long-term savings in maintenance, safety, and energy efficiency make it more economical for industrial projects.

Q4. Can polycarbonate transparent profiles be produced in bulk?

Yes. These profiles can be extruded in large quantities while maintaining quality. Bulk production is ideal for construction firms, retail chains, and manufacturers.

Q5. Why is demand for polycarbonate transparent profiles rising in India?

Rapid industrialisation, growing construction projects, and a preference for safer, longer-lasting materials are driving demand. Their balance of strength and clarity makes them a preferred choice.