Installing window seals might seem like a small task, but it plays a big role in how well uPVC windows perform. If the seal is poorly installed, it can lead to air leaks, noise issues, or even water damage. This is especially true for large projects in different Indian climates.

Many builders, fabricators, and installers choose uPVC window seals in India because they offer long-term protection against dust, heat, and moisture. But even high-quality seals can fail if not installed correctly.

Here are some of the most common installation mistakes and how you can avoid them.

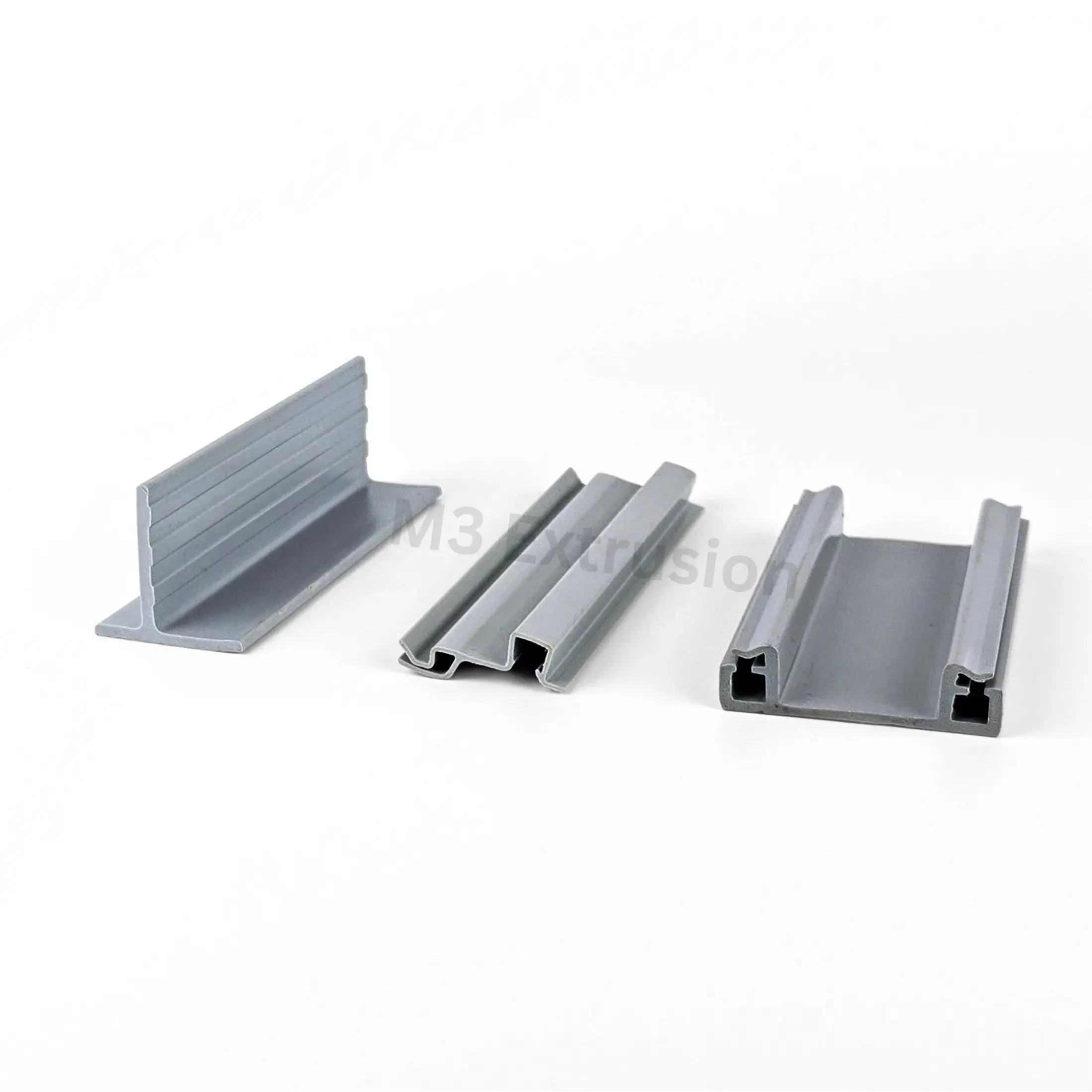

Choosing the Wrong Seal Profile

Using a seal that doesn’t match the window groove leads to loose fitment and poor performance. Every uPVC frame has its own design, and one-size seals often don’t give a perfect match.

Avoid it by working with a seal supplier that can match your window system. For large or ongoing projects, it’s better to use custom-extruded seals that fit your frame precisely.

Not Cleaning the Surface Before Applying the Seal

Dust, grease, or leftover debris on the window surface can reduce the seal’s grip. This creates gaps where water, insects, or air can get in.

Avoid it by cleaning the window groove before applying the seal. Use a dry cloth or a mild cleaner to wipe the area clean for proper contact.

Stretching or Compressing the Seal During Installation

Some installers pull the seal too tightly or press it too hard into the groove, which affects the shape and performance. Over time, this may cause gaps or uneven pressure.

Avoid it by placing the seal naturally, without forcing it. A relaxed, even fit will provide better protection and last longer.

Skipping the Corners and Edges

Corners and joints are often the weakest points in sealing. If these areas are not joined properly, they can easily let in rainwater or dust.

Avoid it by cutting the seal accurately at corners and pressing it firmly into place. Use angled cuts or corner joints as needed for full coverage.

Using the Same Seal Type for Every Location

Weather conditions vary across India. A seal that works well in dry regions may not hold up in coastal or high-rainfall areas.

Avoid it by selecting the right material for the location. For example, EPDM seals are ideal for heat and UV exposure, while TPE seals offer flexibility for residential applications. If you’re unsure, consult your seal supplier for the best match.

To understand more about project-specific sealing, Check:

👉 The Role of Custom-Extruded Seals in Large uPVC Projects

Using Low-Grade Materials to Cut Costs

Cheap seals may save money upfront but often fail early, leading to extra work or client complaints.

Avoid it by working with trusted suppliers of uPVC window seals in India who use tested materials. Always check the durability, flexibility, and weather resistance before bulk buying.

No Post-Installation Testing

Many installers skip testing after fitting the seal. If gaps or loose sections are not fixed early, it can cause problems later.

Avoid it by checking the window after sealing. Open and close it to test movement, air tightness, and contact pressure.

Poor Seal Maintenance Guidance

Clients are rarely told how to care for their seals, which leads to wear and tear over time.

Avoid it by choosing seals that are easy to clean and maintain. Give users basic instructions on how to wipe and check seals regularly.

Why This Matters in Indian Projects

Buildings across India face challenges like monsoon rain, air pollution, coastal salt, and extreme temperatures. If uPVC window seals are not installed correctly, they fail faster and lead to extra repairs or energy loss.

Good sealing helps prevent these issues, keeps interiors protected, and improves window life.

Need Bulk Supply or Profile Matching Help?

M3 Extrusion supports manufacturers, builders, and real estate developers with custom uPVC window seals in India. Our seals are made to match your system, profile, and project scale. We offer tested materials, consistent batches, and reliable delivery.

If you’re managing a project and want to avoid common sealing issues, we can help.

Visit M3 Extrusion to speak to our team or request a quote.

Frequently Asked Questions (FAQ)

Q1. What happens if a window seal is not installed properly?

It can lead to water seepage, air leaks, dust entry, or noise from outside.

Q2. How do I know which seal to use for my project?

Based on your window profile and location, a seal supplier can guide you on the best material and shape.

Q3. Are custom seals more expensive?

They may cost slightly more than standard ones but save time and improve quality in large projects.

Q4. Can you provide seals for different window types?

Yes. M3 Extrusion provides seals for sliding, casement, fixed, and other window systems.

Q5. Do you offer trial samples before bulk orders?

Yes. We can offer samples based on your drawing or sample, to test fit before confirming the order.

Final Words

Avoiding simple mistakes during uPVC window seal installation can save you time, money, and future complaints. Whether it’s a housing project or a commercial building, proper sealing ensures long-term performance.

By choosing the right seal, installing it carefully, and working with reliable suppliers like M3 Extrusion, your project is set up for better results from the start.