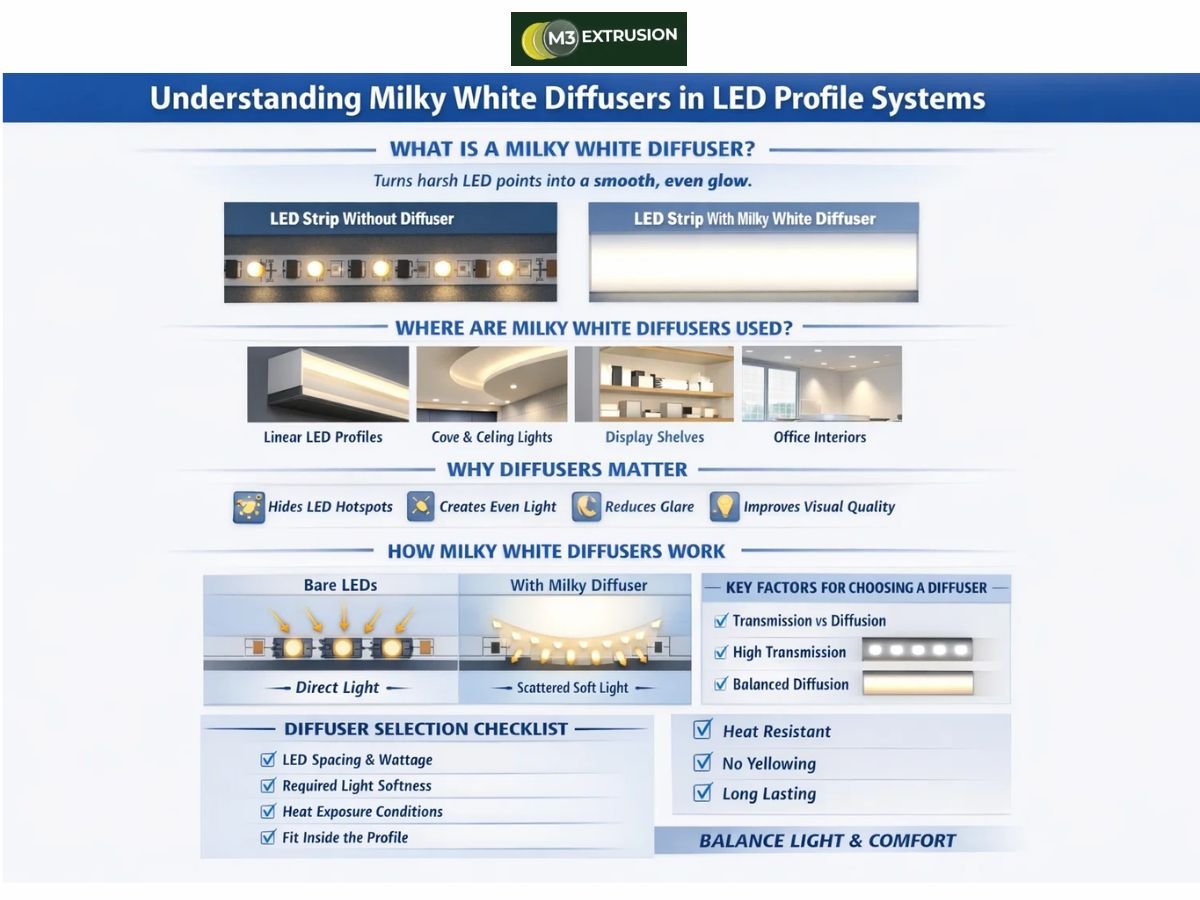

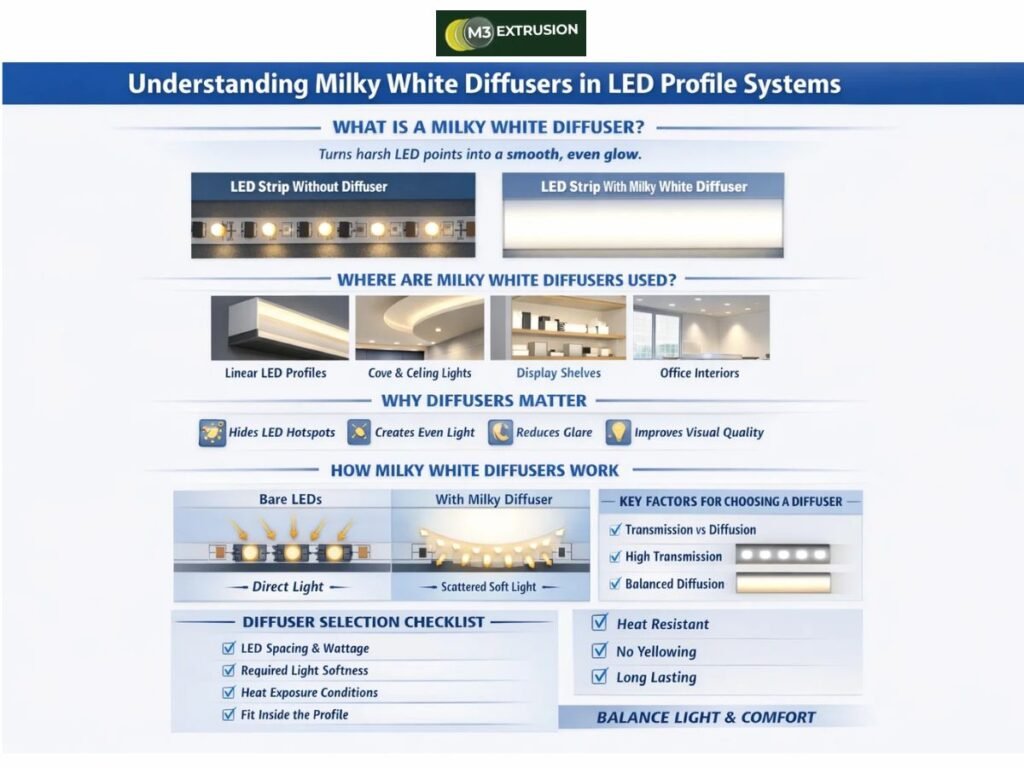

You switch on an LED profile expecting a smooth glow, but instead you see harsh dots and uneven light. This is one of the most common lighting complaints in real projects. In most cases, the issue is not the LED strip. It is the diffuser.

A milky white diffuser plays a quiet but critical role in LED profile systems. It shapes how light looks, feels, and performs over time. For anyone sourcing a white LED diffuser in India, understanding how these diffusers work can make the difference between a clean installation and constant complaints.

What Is a Milky White Diffuser?

A milky white diffuser is a translucent plastic cover fitted over LED strips inside aluminium or plastic profiles. Its main purpose is to spread light evenly and reduce glare.

In simple terms, it turns sharp LED points into a smooth line of light.

Milky white diffusers are widely used in:

- Linear LED profile systems

- Cove and ceiling lighting

- Display shelves and signage

- Commercial and office interiors

Why Diffusers Matter in LED Profile Systems

LED technology has improved quickly, but bare LEDs still produce point light. Without a diffuser, this results in visible hotspots and uncomfortable brightness.

A well-designed milky white diffuser helps:

- Hide individual LED dots

- Create even light distribution

- Reduce eye strain

- Improve the visual quality of the fixture

This is why diffusers are not accessories. They are functional components of the lighting system.

How Milky White Diffusers Work

Milky white diffusers are engineered to scatter light as it passes through the material. The internal structure of the plastic bends and spreads the light in multiple directions.

The result is:

- Softer light output

- Uniform brightness across the profile

- Minimal glare at viewing angles

The quality of diffusion depends on material formulation, thickness, and LED spacing.

Key Factors That Affect Diffuser Performance

1. Light Transmission vs Diffusion

Every diffuser balances two things:

- How much light passes through

- How evenly that light is spread

High transmission with poor diffusion shows LED dots. High diffusion with low transmission makes lighting dull. A good white LED diffuser in India is designed to balance both.

2. Thickness of the Diffuser

Thickness directly impacts performance.

- Thin diffusers allow more light but need closer LED spacing

- Thicker diffusers hide hotspots better but reduce brightness

This is why diffuser selection should always consider the LED strip design.

3. Material Quality and Stability

Low-quality materials may look fine at first but change over time.

Common issues include:

- Yellowing due to heat

- Warping inside the profile

- Surface dullness after cleaning

A stable milky white diffuser maintains its appearance and performance even after long usage hours.

Soft and Uniform Lighting With White LED Diffusers

Many projects today specifically aim for soft and uniform lighting with white LED diffusers, especially in commercial and architectural spaces.

This lighting style is preferred because:

- It reduces harsh shadows

- It feels comfortable for long exposure

- It highlights surfaces without glare

Offices, retail stores, hotels, and showrooms often prioritise this type of lighting over raw brightness.

Matching Diffusers With LED Spacing

One common mistake is selecting a diffuser without checking LED spacing.

Practical guideline

- Closely spaced LEDs work with thinner diffusers

- Widely spaced LEDs require stronger diffusion

Testing a short section before full scale installation helps avoid costly corrections later.

Surface Finish and Visual Appearance

Milky white diffusers differ in surface finish, even if the colour looks similar.

Popular finishes include:

- Smooth matte for clean, modern interiors

- Light texture to further reduce glare

A good diffuser should look neat even when the lights are off, especially in visible installations.

Heat Resistance in Real Conditions

LED profiles can run for many hours each day. Heat build up is unavoidable.

When sourcing a white LED diffuser in India, ensure the material:

- Maintains shape under continuous heat

- Does not crack or become brittle

- Retains colour over time

This is especially important for commercial and retail lighting.

Standard vs Custom Diffusers

Standard diffusers are suitable for basic installations. Custom diffusers are often needed for integrated systems.

Custom milky white diffusers offer:

- Precise fit inside aluminium profiles

- Better alignment with LED placement

- Cleaner assembly with fewer gaps

M3 Extrusion works with lighting manufacturers to produce milky white diffusers matched to specific LED profile designs, helping achieve consistent light output and repeatable quality in production runs.

Common Issues Seen on Site

Based on real installation feedback, these problems appear often:

- Diffuser selected only by colour name

- Ignoring LED wattage and spacing

- Using indoor grade diffusers in high heat areas

- Expecting one diffuser to suit all applications

Understanding diffuser behaviour early avoids these issues.

Quick Selection Checklist

Before finalising a milky white diffuser, confirm:

- Required light softness and brightness

- LED spacing and wattage

- Heat exposure conditions

- Visual finish when lights are off

- Fit inside the LED profile

This simple check prevents most lighting complaints.

Key Takeaways

- Milky white diffusers control how LED light feels, not just how it looks

- The right diffuser improves comfort and visual consistency

- Material quality and design matter more than colour name

- LED and diffuser should be selected as one system

A well chosen white LED diffuser in India helps deliver lighting that performs well and looks right for years.

Frequently Asked Questions

What is a milky white diffuser used for?

A milky white diffuser is used to soften LED light and hide individual LED points. It creates a smooth, even glow that improves visual comfort. These diffusers are commonly used in LED profile systems for commercial, office, and architectural lighting.

Does a milky white diffuser reduce LED brightness?

Yes, a milky white diffuser slightly reduces brightness, but it improves light quality. The goal is even illumination, not raw output. A good diffuser balances light transmission and diffusion so the space feels well lit without glare.

How do I choose the right diffuser for my LED profile?

Choose a diffuser based on LED spacing, brightness, and application. Closer LED spacing allows thinner diffusers, while wider spacing needs stronger diffusion. Always consider heat exposure and test samples before final installation.

Are milky white diffusers suitable for long usage hours?

Milky white diffusers made from stable materials are suitable for long daily usage. They maintain shape and colour under continuous heat, making them ideal for offices, retail spaces, and commercial environments.

Why do some diffusers turn yellow over time?

Yellowing usually occurs due to poor material quality or heat resistance. High quality diffuser materials are formulated to resist discolouration and maintain clarity over time, even in LED profiles that run for extended hours.

Can milky white diffusers be customised?

Yes, milky white diffusers can be customised in shape, thickness, and diffusion level. Custom diffusers help achieve better fit, cleaner installation, and more uniform lighting, especially in integrated LED profile systems.

Check related articles for more insights: