If you have stepped into a modern office with sleek partitions, walked under a greenhouse roof, or noticed transparent roofing sheets on an industrial shed, you have likely seen polycarbonate in action. The demand for polycarbonate profile in India is increasing steadily, and the reasons are clear. This material combines toughness with lightness, giving industries a solution that is durable, adaptable, and easy to handle.

What Makes Polycarbonate Profiles Different?

Polycarbonate is often described as the all-rounder of plastics. Unlike glass that can shatter or metals that corrode over time, polycarbonate remains strong while offering design flexibility.

Some qualities worth knowing:

- High impact resistance, making it difficult to crack.

- Excellent light transmission, ideal for skylights and glazing.

- UV stability, which prevents yellowing even in hot climates.

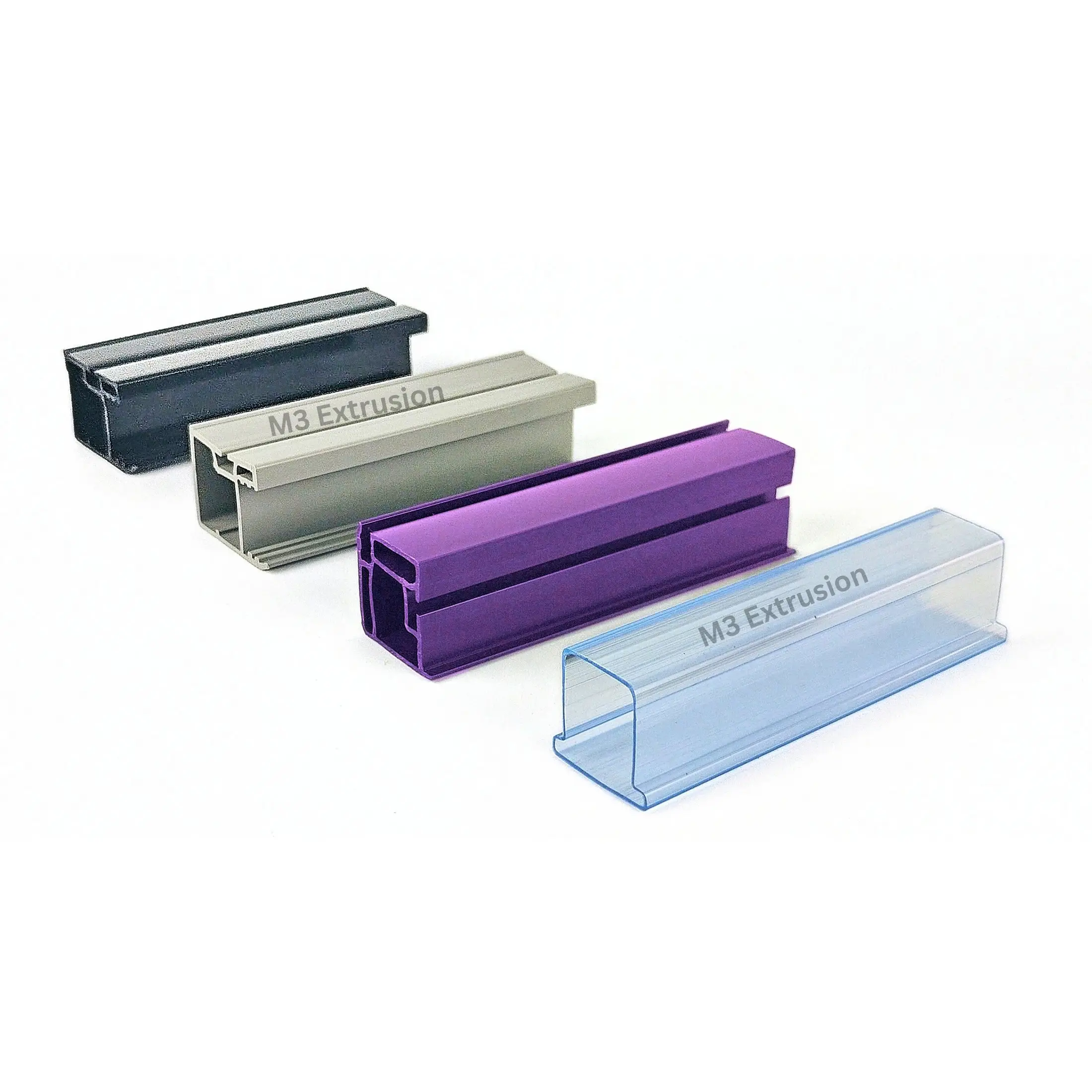

- Ability to be extruded into varied shapes and sizes, from U and H connectors to complex customised profiles.

This versatility makes it suitable for both large construction projects and smaller design applications.

Why Industries Prefer It

Consider this example. A warehouse roof made of heavy glass would be costly to install and difficult to maintain. Replace that with polycarbonate profiles, and you have a solution that is lighter, easier to fix, and more cost-efficient over time.

For industries, polycarbonate profiles bring benefits such as:

- Reduced maintenance compared to fragile or heavy alternatives.

- Availability in bulk for ongoing projects.

- Compatibility with materials like aluminium and uPVC, allowing mixed system use.

Where Polycarbonate Profiles Are Used

Roofing and Skylights

Greenhouses, malls, and industrial sheds use them for strong yet light roofing that keeps interiors bright.

Office Interiors

Modern workplaces prefer clear or frosted partitions. Polycarbonate profiles provide a professional finish without the heaviness of glass.

Industrial Protection

Machine guards and protective covers rely on polycarbonate because it combines strength with visibility.

Agriculture

Farmers choose polycarbonate for greenhouses as it protects crops while still allowing sunlight to pass through.

Supporting Long-Term Efficiency

Every project manager looks for ways to balance cost and durability. Polycarbonate profiles help in both areas. They may not always be the cheapest option upfront, but they last longer and require fewer replacements, which saves money in the long run.

In Indian cities where summers bring extreme heat and monsoons bring heavy rains, this material has proven reliable. Contractors and builders appreciate that stability because it keeps projects running smoothly over time.

Practical Tips for Choosing Profiles

- Always check for proper UV protection when using profiles outdoors.

- Select thickness based on the purpose of the project rather than assuming thicker is always better.

- Work with trusted suppliers to avoid inconsistent quality.

- Ensure careful installation for better lifespan and performance.

India’s Growing Use of Polycarbonate

The rise of polycarbonate profiles in India highlights a shift in how industries are selecting materials. Builders, manufacturers, and farmers are all recognizing the value of a product that works across climates and applications. This growth also shows how businesses are seeking durable, practical solutions instead of quick fixes.

At M3 Extrusion, we have seen this demand first-hand. By supplying industries with polycarbonate profiles in bulk and custom orders, we support businesses that want reliable materials for long-term use.

FAQs

Q1. Are polycarbonate profiles stronger than glass?

Yes, they are far more impact resistant while being lighter to handle.

Q2. Can they withstand India’s climate?

Yes, with UV protection and weather resistance, they are well suited for outdoor use.

Q3. Can profiles be customized?

Yes, extrusion allows them to be made in specific shapes and sizes for unique requirements.

Q4. Do they help reduce energy costs?

They allow natural light while filtering harmful rays, reducing the need for artificial lighting.

Q5. Which sectors use them most?

Construction, agriculture, office interiors, and industrial manufacturing all rely on polycarbonate profiles.

Final Thoughts

Polycarbonate profiles have become an essential material for modern projects. They bring together strength, lightness, and design flexibility in a way that meets today’s industrial and commercial needs. Whether for roofing, interiors, or protective solutions, polycarbonate continues to prove its value in building and manufacturing projects across India.