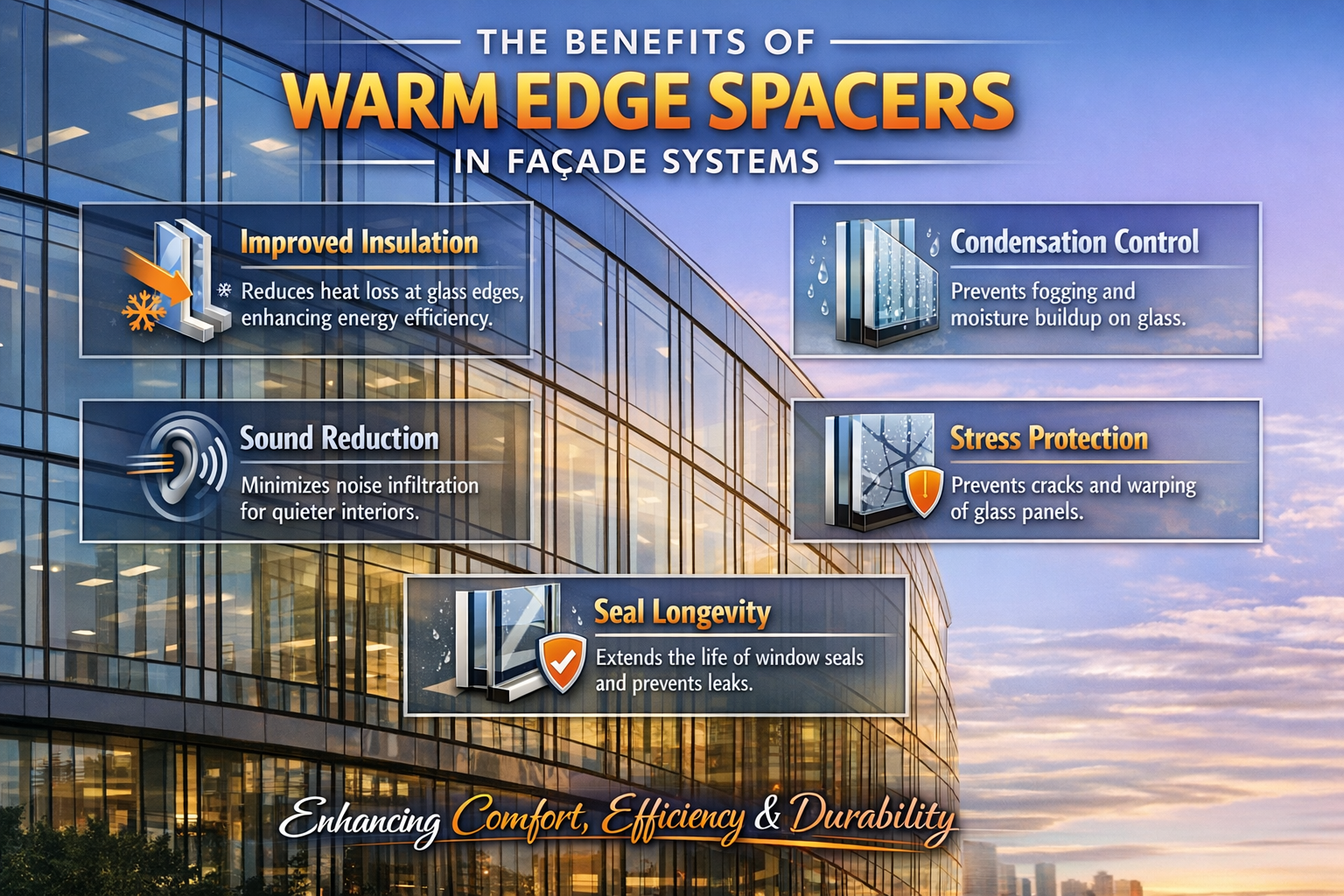

Whether you want to reduce heat loss through windows or reduce maintenance costs in your building’s façades, using warm edge spacers can make a big difference. Not only do warm edge spacers in India improve energy efficiency, but they also help protect your building from damage caused by condensation and thermal stress.

These spacers sit between panes in double- or triple-glazed windows, reducing heat transfer and keeping indoor temperatures stable.

In façades, they limit moisture buildup around the glass edges, preventing corrosion, leaks and other maintenance issues that can affect industrial operations. Using warm edge spacers also reduces the load on heating and cooling systems.

This can lower energy bills and make temperature control more reliable, which is critical in manufacturing units, warehouses and large commercial buildings.

By minimising cold spots around windows and façades, they help maintain a consistent indoor environment, improving comfort for employees and protecting sensitive equipment.

Warm edge spacers come in materials such as stainless steel, silicone foam as well as thermoplastics, all designed to transfer less heat than traditional metal spacers. Proper installation ensures they perform effectively over the long term. For industrial facilities, investing in warm edge spacers is a practical way to save energy, cut maintenance costs and extend the life of windows and façades.

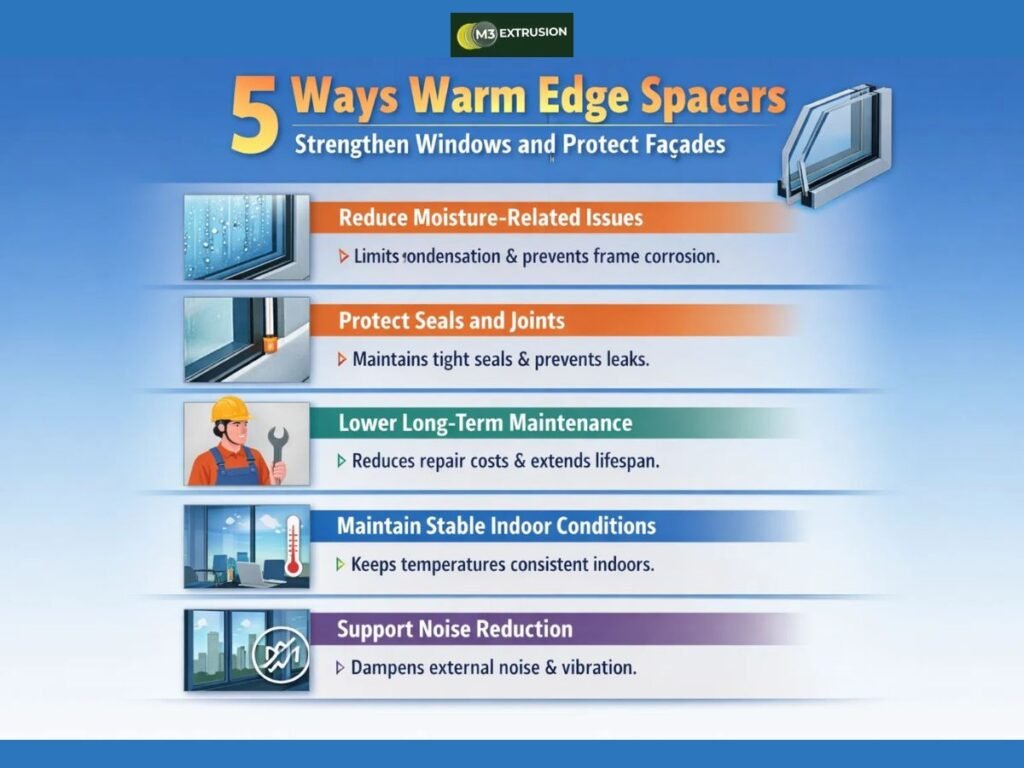

5 Ways Warm Edge Spacers Strengthen Windows and Protect Façades

In today’s industrial facilities, warm edge spacers help windows and façades resist heat loss, moisture, and structural stress. By supporting the perimeter of the glass, warm edge spacers reduce stress on seals and frames, helping windows and façades maintain long-term reliability.

Industrial buildings with large glass surfaces face constant temperature changes, heavy use and exposure to moisture. Warm edge spacers address these challenges by maintaining tight seals and minimising the risk of leaks, corrosion and frame damage.

For windows, these spacers improve edge stability and reduce the chance of seal failure or warping, ensuring consistent performance even in harsh climates. In façades, they prevent water buildup, safeguard the structure and reduce maintenance work.

This reliability is crucial for warehouses, manufacturing units as well as commercial facilities where equipment and processes can be sensitive to environmental changes.

Not to mention, warm edge spacers work with many types of glass and façade designs, making them suitable for both new construction and renovations. By reducing cold spots and temperature fluctuations along edges, they help maintain a consistent indoor environment, improve comfort for staff and protect sensitive equipment.

Here are five ways warm edge spacers strengthen windows and protect façades:

Reduce moisture-related issues

One of the major benefits of warm edge spacers is their ability to control moisture in windows and façades. By keeping glass edge temperatures more balanced, these spacers reduce the conditions that lead to condensation. This helps protect glazing systems from moisture-related damage in industrial environments.

- Limits condensation buildup: Warm edge spacers reduce cold spots along glass edges in windows as well as façades, which lowers the chance of condensation forming during temperature changes.

- Protects seals and frames: By minimising moisture at the edges, warm edge spacers help prevent seal damage, frame corrosion, and water entry in both window and façade systems.

- Reduces surface deterioration: With lower moisture buildup at glass edges, warm edge spacers help prevent cracking, staining, and material breakdown in frames and surrounding façade components during long-term industrial use.

By reducing moisture-related issues, warm edge spacers help windows and façades remain stable, durable, and easier to maintain throughout their service life.

Protect seals and joints

In addition to reducing moisture-related issues, warm-edge spacers also help protect seals and joints in windows as well as façades. By limiting temperature differences at glass edges, they reduce stress on sealing materials and help maintain a tight, reliable connection over time.

- Reduces seal stress: Warm edge spacers limit expansion and contraction caused by temperature changes, helping window and façade seals remain intact during daily and seasonal shifts.

- Prevents air and water entry: It helps maintain tight seals at glass edges, limiting drafts and water intrusion in window and façade systems used in industrial buildings.

- Supports long-term performance: By protecting seals and joints from early wear, warm edge spacers help windows and façades maintain consistent performance and reduce the need for repairs.

Overall, warm edge spacers help maintain long-term reliability in windows and façades by limiting wear on seals and joints.

Lower long-term maintenance needs

Without a doubt, a major benefit of warm edge spacers is that they reduce long-term maintenance for windows as well as façades. By improving edge performance and limiting common failure points, they help buildings stay functional with fewer repairs over time.

- Reduces repair frequency: Warm edge spacers help prevent seal failure, condensation damage and edge wear, which lowers the need for repeated repairs in window and façade systems.

- Reduces material fatigue: It helps distribute stress evenly along window and façade edges, preventing premature wear or weakening of frames, seals and glass. This lowers the likelihood of long-term damage and reduces the frequency of major maintenance.

- Enhances edge stability: Warm edge spacers help support the edges of glass panes in windows and façades, reducing stress from temperature changes and preventing cracks, warping or other damage that can shorten the lifespan of the glazing.

By reducing stress on seals, frames, and glass edges, warm edge spacers help lower ongoing maintenance needs while keeping windows and façades durable and reliable.

Maintain stable indoor conditions

Since warm edge spacers reduce heat transfer at glass edges, they help maintain more consistent indoor temperatures in windows and façades. This supports employee comfort, protects sensitive equipment and ensures stable conditions in industrial buildings.

- Reduces cold and hot spots: Warm edge spacers limit temperature variations near the window and façade edges, creating a more even indoor environment throughout the building.

- Prevents localised temperature fluctuations: It stabilises temperatures along the edges of windows and façades, ensuring a uniform environment and avoiding hot or cold spots that can affect operations.

- Improves temperature consistency: Warm edge spacers reduce heat loss or gain at glass edges, helping maintain uniform indoor temperatures across windows and façades in industrial facilities.

With warm edge spacers, industrial facilities benefit from stable indoor conditions that enhance comfort, protect assets and support smooth day-to-day operations.

Support noise reduction

Warm edge spacers create a tighter seal between glass panes, which helps reduce noise transmission through windows and façades. This is especially important in industrial facilities where machinery and external activity generate high sound levels.

- Limits external noise: Warm edge spacers help dampen sound from outside, reducing disturbances in manufacturing units, warehouses or commercial spaces.

- Reduces vibration transfer: They strengthen glass edges, minimising vibrations that can amplify sound within windows and façades.

- Improves sound insulation consistency: Warm edge spacers in India help maintain uniform spacing between glass panes, ensuring that windows as well as façades provide consistent sound insulation across the entire surface. This reduces uneven noise levels in industrial buildings.

With enhanced sealing at glass edges, these spacers not only reduce noise transmission but also create calmer, more controlled indoor conditions in windows as well as façades.

Investing in warm edge spacers enhances both windows as well as façades, improving energy efficiency, reducing maintenance needs, supporting stable indoor conditions, and minimising noise. For industrial facilities, they provide long-term reliability, protect equipment and create a safer, more comfortable work environment.

Are you looking for warm edge spacers to improve the performance and durability of your windows and façades? M3 Extrusion offers high-quality warm edge spacer PVC profiles for industrial applications, helping reduce maintenance, enhance energy efficiency, and maintain stable indoor conditions.

Frequently Asked Questions

Can warm edge spacers prevent condensation?

Yes. Warm edge spacers reduce cold spots at the edges of windows and façades. This limits moisture buildup, prevents condensation and protects glass panels, frames, and surrounding structures from damage caused by water or mould.

Are warm edge spacers suitable for large façades?

Yes. Warm edge spacers are designed for use in large glass façades and curtain walls. They help maintain structural stability, minimise condensation and improve energy performance across expansive industrial and commercial building surfaces.

Do warm edge spacers reduce maintenance needs?

By limiting condensation, protecting seals, and stabilising glass edges, warm edge spacers reduce the risk of leaks, corrosion, and frame damage. This reduces how often windows and façades need repairs or maintenance.

Do warm edge spacers contribute to energy savings?

Yes. By lowering heat transfer through the edges of glass, warm edge spacers lower the demand on heating and cooling systems. This decreases energy consumption, helping industrial facilities save on energy costs and operate more efficiently.

How long do warm edge spacers last?

Warm edge spacers are durable and can keep windows as well as façades performing well for many years. Generally, their durability depends on material choice, installation quality, and building conditions, but they consistently provide long-term thermal performance and protection.

Check related articles for more insights:

- Industrial Applications of Warm Edge Spacers in Double-Glazed Windows

- 7 Ways Warm Edge Spacers Reduce Heat Loss in Industrial Windows

- 6 Cost Advantages of Using Warm Edge Spacers in Large-Scale Projects

- How Warm Edge Spacers Address Thermal Bridging in Modern Architecture