In electronics manufacturing, one small misstep in component selection can ripple across an entire production line. Electric PCB rail profiles might seem like minor accessories, but they play a crucial role in securing circuit boards, ensuring electrical safety, and supporting long-term performance. In India, industries are increasingly focusing on electric PCB rail profiles in India that meet high-quality standards while supporting bulk production and automated assembly.

Choosing the right profile requires attention to design, material, tolerances, and compatibility with existing systems. This article explains key considerations, practical tips, and real-world insights for making informed decisions.

Understanding Electric PCB Rail Profiles

Electric PCB rail profiles are extruded plastic or polymer channels designed to hold printed circuit boards (PCBs) securely in place. They act as structural supports, insulating barriers, and guides for automated assembly processes.

Key features include:

- Material Strength: Ensures the rail supports PCB weight without bending.

- Electrical Insulation: Prevents short circuits and protects components.

- Dimensional Accuracy: Maintains alignment during assembly and operation.

Industries like LED manufacturing, industrial electronics, and automation rely on these profiles to streamline production and reduce assembly errors.

Why Selecting the Right Profile Matters

Even a slight deviation in profile dimensions or material properties can lead to:

- PCB misalignment during assembly

- Contact with other components causing shorts

- Difficulty in mounting or dismounting boards

- Long-term durability issues in demanding environments

Proper selection improves efficiency, reduces downtime, and maintains product quality.

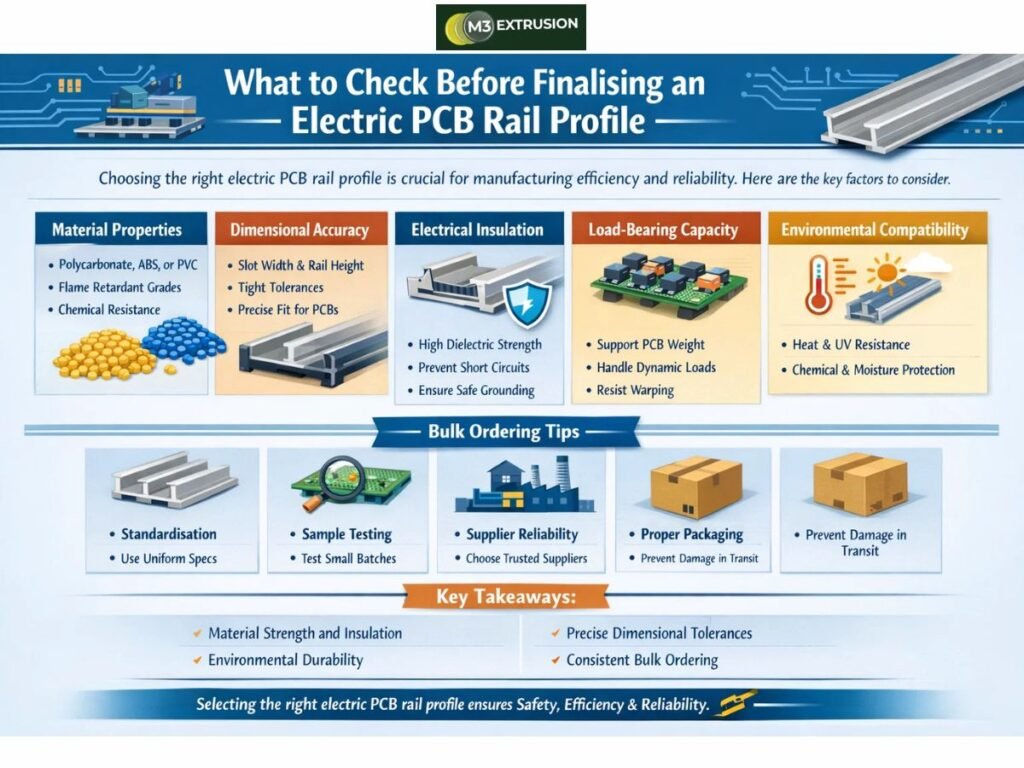

Key Factors to Check Before Finalising

1. Material Properties

The material must meet the functional needs of your assembly:

- Polycarbonate or ABS: For heat resistance and durability

- PVC or high-impact plastics: For cost-effective, lightweight solutions

- Flame retardant grades: Essential for high-power PCBs

Check chemical resistance if your PCBs will be exposed to cleaning agents or industrial chemicals.

2. Dimensional Accuracy and Tolerances

Precision matters in automated assembly. Measure and verify:

- Slot width for PCB thickness

- Rail height and length for proper fit in enclosures

- Edge clearance for connectors and components

Even small tolerance deviations can disrupt assembly and lead to repeated errors.

3. Electrical Insulation

Electric PCB rail profiles must:

- Provide adequate dielectric strength

- Prevent accidental contact with metallic enclosures

- Support grounding requirements where needed

This ensures both safety and compliance with regulatory standards.

4. Load-Bearing Capacity

Consider the weight of PCBs, including mounted components. Profiles should support:

- Single boards or stacked assemblies

- Dynamic loads during automated handling

- Thermal expansion without warping

This helps prevent mechanical failure and ensures long-term reliability.

5. Environmental Compatibility

Profiles may face temperature extremes, humidity, or chemical exposure. Evaluate:

- Heat resistance for high-power electronics

- UV resistance for outdoor enclosures

- Resistance to solvents, oils, or dust in industrial spaces

Proper environmental selection reduces maintenance and replacement frequency.

Bulk Ordering Tips for PCB Rail Profiles

When procuring large quantities, keep these points in mind:

- Standardisation: Use the same material and dimensions across batches for consistency.

- Sample Testing: Validate a small batch before committing to bulk orders.

- Supplier Reliability: Choose a manufacturer capable of meeting large-volume demands without quality compromise.

- Packaging and Handling: Ensure rails arrive protected from bending, scratches, or contamination.

Following these bulk ordering tips for PCB rail profiles helps prevent disruptions in high-volume assembly lines and ensures smooth production.

Installation and Handling Best Practices

Even the best profiles can underperform without proper handling:

- Store rails in flat, dry conditions

- Avoid excessive bending or force during installation

- Ground operators and tools to prevent static discharge

- Check alignment in automated feeders before full production

These practices maintain structural integrity and reduce rework.

Real-World Manufacturing Insights

In large-scale LED PCB assembly, switching to precision electric PCB rail profiles reduced misalignment by over 20%, cut assembly errors, and minimized downtime. Factories that focus on accurate dimensions, quality material, and bulk consistency see measurable improvements in efficiency and lower rejection rates.

Manufacturers like M3 Extrusion in India offer high-quality electric PCB rail profiles with consistent tolerances, helping industrial clients maintain smooth, repeatable operations even in high-volume production environments.

Key Takeaways

- Material choice, dimensional accuracy, and electrical insulation are crucial for electric PCB rail profiles.

- Environmental compatibility ensures long-term performance in industrial settings.

- Bulk ordering requires testing, standardisation, and reliable suppliers to maintain production efficiency.

- Proper handling and installation maintain durability and prevent assembly errors.

Selecting the right electric PCB rail profile ensures safety, efficiency, and reliability across the assembly line.

FAQs About Electric PCB Rail Profiles

What is an electric PCB rail profile?

An electric PCB rail profile is an extruded component that supports, aligns, and insulates PCBs in industrial and commercial assemblies, ensuring safe and reliable operation.

How do I choose the right PCB rail profile?

Consider material strength, dimensional tolerances, electrical insulation, load capacity, and environmental resistance to match the profile with your specific PCB application.

Can electric PCB rail profiles be used in automated assembly?

Yes, profiles designed to precise tolerances integrate smoothly with pick-and-place systems, conveyor lines, and other automated assembly equipment.

Are there bulk ordering considerations for PCB rail profiles?

Yes, always standardise dimensions, test samples before full orders, select reliable suppliers, and ensure proper packaging to prevent damage during transport.

How long do electric PCB rail profiles last?

Lifespan depends on material, environmental exposure, and handling. High-quality ABS or polycarbonate rails typically last years under normal industrial conditions.

Can PCB rail profiles handle high temperatures?

Profiles made from heat-resistant materials like polycarbonate or flame-retardant PVC can withstand elevated temperatures in high-power applications.

Do electric PCB rail profiles provide electrical insulation?

Yes, most profiles are designed to prevent short circuits and protect PCBs from accidental contact with metallic enclosures or other components.

Summary

Finalising an electric PCB rail profile in India requires careful attention to material, tolerance, insulation, load capacity, and environmental conditions. Following bulk ordering tips for PCB rail profiles and proper handling ensures consistent performance in high-volume industrial assembly. Using high-quality profiles supports efficiency, safety, and reliability, making them a vital component in modern electronics manufacturing.

Check related articles for more insights: