Walk through any modern building, and you will see clean lines, tight joints, and materials that quietly do their job year after year. Many of those details rely on rigid plastic profiles. In India, the use of rigid PVC profiles has grown steadily because builders and manufacturers need materials that hold shape, handle load, and remain stable in demanding conditions.

These profiles are not decorative add ons. They are functional building components used where accuracy, durability, and repeat performance matter.

What Are Rigid Plastic Profiles

Rigid plastic profiles are extruded components made from materials like rigid PVC and similar engineering plastics. They are produced in fixed cross sections and cut to required lengths for use in buildings.

Unlike flexible plastics, rigid profiles:

Hold their shape under load

Maintain dimensional stability

Support structural alignment

They are manufactured using extrusion, which allows consistent shape control across large production volumes.

Why Builders and Manufacturers Choose Rigid PVC Profiles

From site experience and manufacturing feedback, rigid plastic profiles are selected for a few practical reasons.

They do not warp easily with temperature change

They resist moisture and common construction chemicals

They support repeat installation without adjustment

For building projects that demand uniformity across floors or facades, rigid PVC profiles reduce rework and alignment issues.

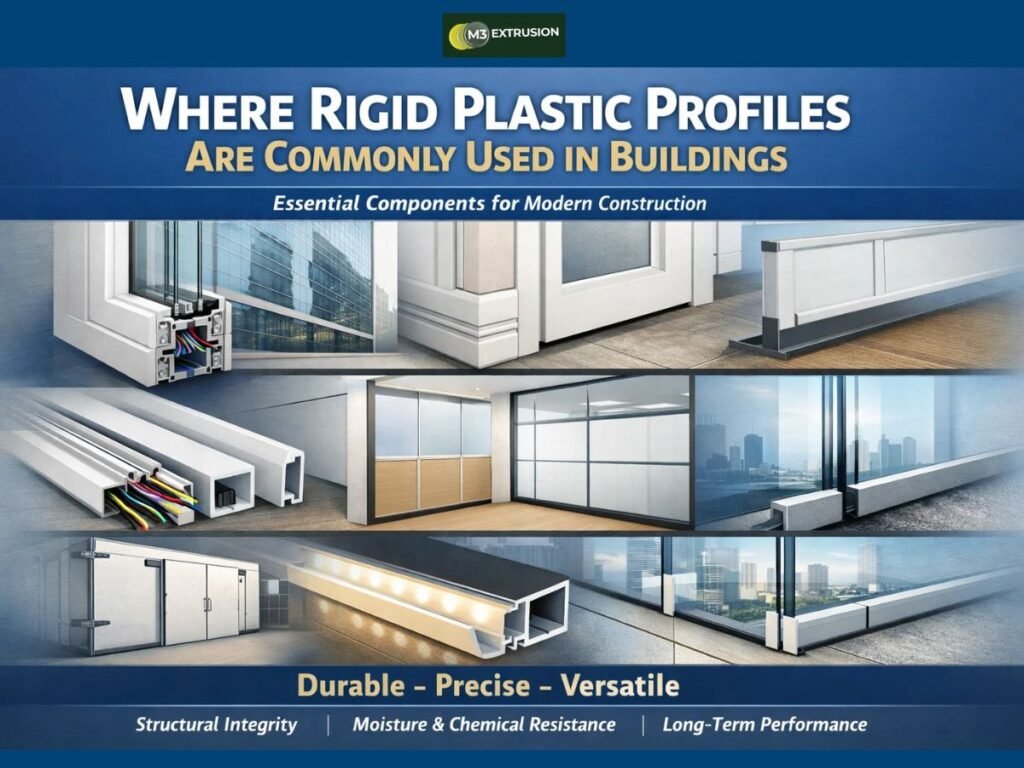

Common Building Applications of Rigid Plastic Profiles

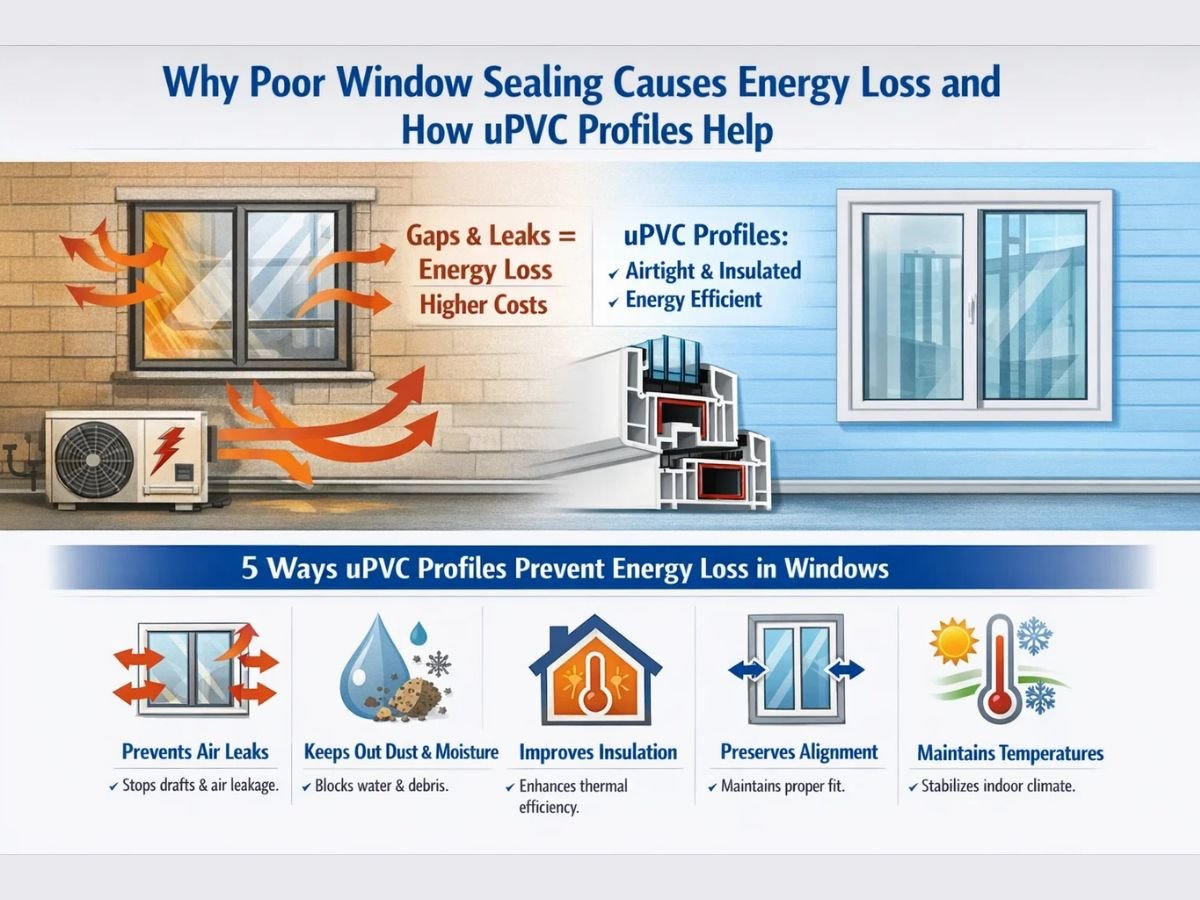

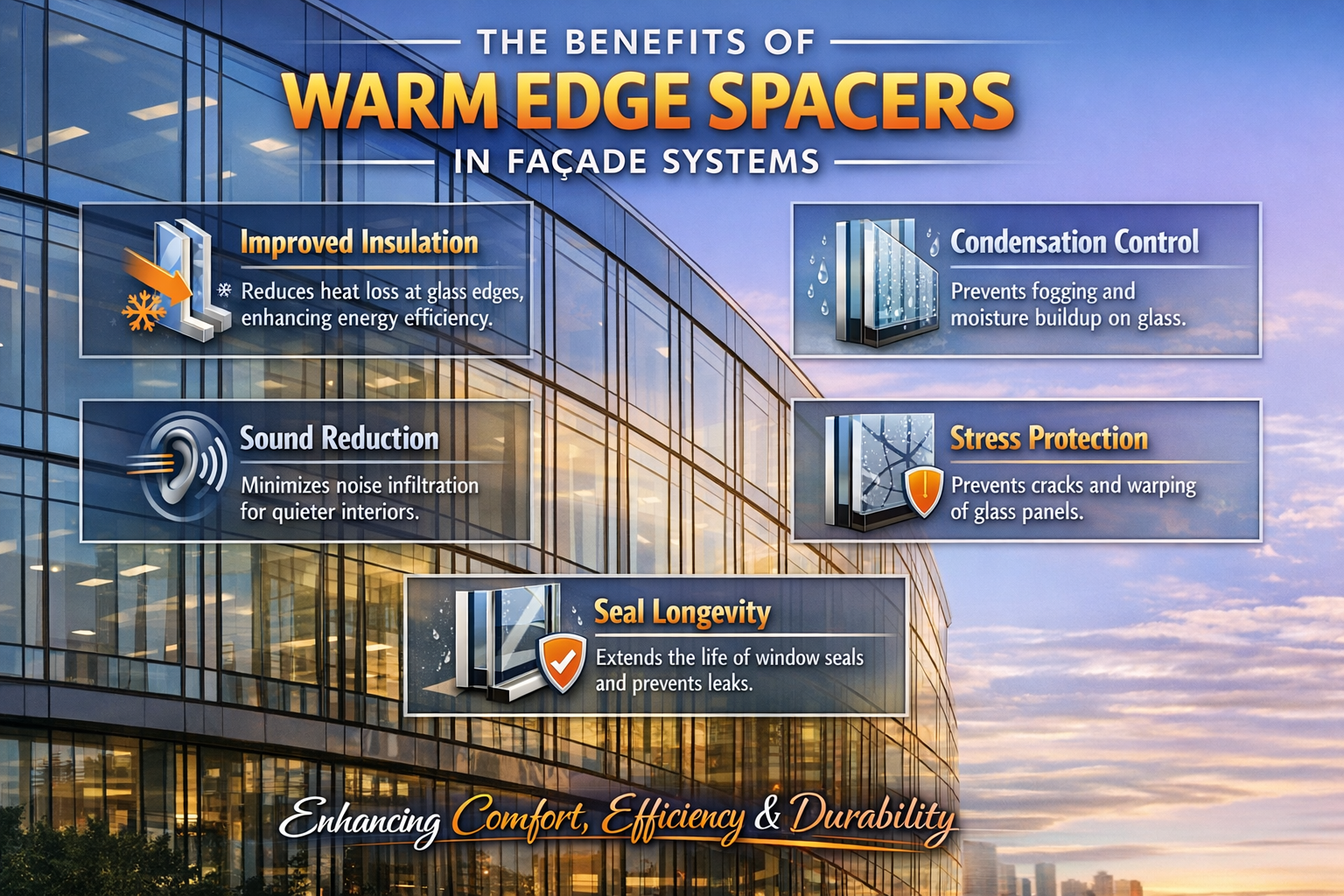

1. Window and Façade Systems

One of the most visible uses is in window frames and façade assemblies.

Rigid plastic profiles are used as:

Spacers and structural inserts

Support profiles inside composite window systems

Frame elements for curtain walls

In façade construction, consistent profile geometry helps glass panels align properly. This improves sealing, reduces air gaps, and supports thermal performance.

2. Door Frames and Threshold Components

Commercial buildings often use rigid plastic profiles inside door systems where metal alone would increase weight or cost.

Typical uses include:

Reinforcement profiles inside PVC doors

Threshold separators between flooring materials

Alignment guides for sliding systems

These components improve fit and reduce wear in high traffic areas.

3. Electrical and Cable Management Systems

Rigid plastic profiles are widely used to organise and protect electrical systems.

In buildings, they appear as:

Cable trunking

Raceway covers

Panel separation profiles

Their insulating properties and clean edges make them suitable for commercial interiors, control rooms, and service corridors.

4. Interior Partitions and Panels

Office buildings and commercial spaces rely on modular partition systems.

Rigid plastic profiles are used to:

Hold panels in place

Separate materials like glass and laminate

Maintain straight joints over long spans

These profiles help installers maintain alignment without constant adjustment.

5. Industrial Applications of Rigid PVC Profiles in Buildings

Beyond visible spaces, many rigid plastic profiles support industrial building functions. This includes cold storage units, service areas, and utility zones.

In these settings, profiles are used in:

Commercial refrigerator door frames

Cold room panel systems

Equipment enclosures

These industrial applications of rigid PVC profiles require tight tolerances and long term shape retention, especially where temperature variation is constant.

This is also where repeat production matters. Manufacturers need the same profile to fit every unit without variation.

6. LED Lighting and Diffuser Systems

Modern buildings rely heavily on integrated lighting.

Rigid plastic profiles are used as:

LED diffuser covers

Housing channels for linear lights

Support rails inside aluminium systems

These profiles control light spread while protecting internal components from dust and impact.

7. Glass Processing and Glazing Support

Heavy glass structures depend on accurate spacing and separation.

Rigid plastic profiles act as:

Spacers between glass panels

Edge protection during installation

Support elements during transport

They prevent contact damage and maintain consistent gaps.

Why Custom Profiles Matter in Building Projects

Standard shapes often do not meet project-specific needs.

Custom rigid plastic profiles allow:

Exact fit based on drawings

Integration with other materials

Consistency across large batches

This is especially important in commercial projects where one mismatch can affect hundreds of units.

Manufacturers like M3 Extrusion work closely with builders, façade companies, and equipment makers to produce profiles that match technical specifications and support repeat supply.

How Rigid Plastic Profiles Support Long-Term Performance

From real project experience, the long term value comes from stability.

Rigid profiles help buildings by:

Reducing movement between materials

Supporting clean finishes over time

Lowering maintenance needs

When profiles maintain their shape, doors close properly, panels stay aligned, and systems continue to function as intended.

Key Takeaways for Builders and Specifiers

If you are selecting materials for a building project, rigid plastic profiles offer practical advantages.

Suitable for structural and functional uses

Reliable in large scale and repeat applications

Compatible with modern construction systems

Their role may be subtle, but their impact on performance is significant.

FAQs About Rigid Plastic Profiles in Buildings

Where are rigid PVC profiles most commonly used in buildings?

Rigid PVC profiles are commonly used in window systems, façades, door frames, cable management, LED lighting housings, and commercial refrigeration units. Their stable shape and moisture resistance make them suitable for both interior and exterior building applications.

Why are rigid plastic profiles preferred over metal in some building uses?

Rigid plastic profiles are lighter than metal, resist corrosion, and do not conduct electricity. They also allow precise extrusion shapes, making them suitable for applications where alignment, insulation, and repeat installation are important.

Are rigid PVC profiles suitable for long-term building use?

Yes, rigid PVC profiles are designed for long-term use. When manufactured correctly, they maintain shape, resist environmental stress, and support consistent performance in buildings over many years.

Can rigid plastic profiles be customised for specific projects?

Rigid plastic profiles can be produced in custom shapes based on drawings and technical needs. This allows builders and manufacturers to match exact dimensions, materials, and functional requirements for each project.

What industries commonly use rigid plastic profiles in buildings?

Industries include commercial construction, façade manufacturing, glass processing, cold storage, and LED lighting. These sectors rely on rigid profiles for consistency, durability, and repeat production.

How do rigid plastic profiles support repeat manufacturing?

Rigid profiles are extruded with controlled tolerances, ensuring every piece matches the previous one. This consistency is essential for repeat manufacturing, large projects, and standardised building systems.

Check related articles for more insights:

- Materials Used in Rigid PVC Profiles and Their Advantages

- How Rigid PVC Profiles Improve Efficiency and Sustainability in Building.

- Why Rigid PVC Profiles are a Cost-Effective Solution for Indian. Manufacturers

- Top Applications of Rigid PVC Profiles in the Indian Construction Industry.