As India’s construction and architecture sectors focus more on sustainability and energy savings, building materials are undergoing significant innovation. Among these, warm edge spacers play an essential role in improving the energy performance of insulated glass units (IGUs) in residential and commercial projects. By minimising heat transfer at the edges of glazing units, these spacers help reduce energy costs and improve indoor comfort.

What Is a Warm Edge Spacer?

A warm edge spacer is the strip or frame that separates the panes of glass in double or triple glazing. It plays a crucial role in preventing heat loss, condensation build-up, and gas leakage from the space between glass panes. Unlike traditional aluminium spacers, modern warm edge spacers are designed to offer better insulation, flexibility, and durability. These features are especially important in India, where climatic variations demand high-performing, moisture-resistant materials.

Latest Materials Used in Warm Edge Spacers

1. Advanced Plastics and Hybrid Compounds

The most noticeable change in spacer technology comes from the use of high-performance plastics. These advanced polymers offer low thermal conductivity, ensuring better insulation properties. Some designs include hybrid compounds, blending polypropylene or polycarbonate with stainless steel layers to combine flexibility with strength.

Benefits

- Excellent thermal insulation

- Flexibility for various window systems

- UV stability for long-lasting performance in sunny climates like India

2. Stainless Steel

Stainless steel continues to be part of innovative warm edge spacer designs, usually in thin layers that add rigidity and prevent structural deformation. Its corrosion resistance is ideal for coastal and humid regions of India, making it valuable for large commercial buildings.

Benefits

- High mechanical strength

- Corrosion resistance suitable for India’s coastal zones

- Long service life with minimal degradation

3. Thermoplastics

Thermoplastics such as PVC and TPU (thermoplastic polyurethane) are increasingly used because they are easy to process, cost-effective, and provide reliable insulation. These spacers are also recyclable, making them attractive for sustainable building projects.

Benefits

- Cost-efficient for mass production

- Lightweight and easy to handle

- Suitable for a variety of Indian building types

4. Structural Foam

Structural foams, often combined with silicone, provide excellent thermal breaks and reduce energy loss in IGUs. These spacers are flexible and maintain strong gas and moisture seals over time.

Benefits

- Superior insulation performance

- Reliable flexibility for shaped and curved glazing

- Long-term sealing ability that reduces energy loss

5. Specialised Coatings and Diffusion Barriers

Modern warm edge spacers feature advanced barrier layers and coatings that prevent moisture and gas leakage, extending the life of IGUs. These coatings also contribute to maintaining low U-values essential for energy-efficient glass facades in India’s climate zones.

Benefits

- Prevent gas diffusion and moisture ingress

- Maintain insulating gas fill integrity over time

- Improve overall unit lifespan

Why These Materials Matter for Indian Construction

India’s climate varies greatly—from humid coastlines to arid interiors and snowy mountain regions. This diversity requires spacer materials that can withstand temperature extremes, high UV exposure, and moisture without degrading. Materials like advanced plastics, stainless steel hybrids, and structural foams are ideal for these conditions because they deliver thermal efficiency, moisture resistance, and structural integrity. They also help reduce energy demand for cooling and heating in Indian buildings, making them suitable for both commercial skyscrapers and residential flats.

The Growing Demand for Warm Edge Spacers in India

With India pushing towards green building certifications such as IGBC and GRIHA, demand for warm edge spacers has increased. Glass processors, façade manufacturers, and real estate developers are specifying these spacers for use in high-performance window systems.

Key Indian industries adopting warm edge spacers include:

- Commercial façade systems

- Residential high-rise glazing

- Industrial warehouses requiring temperature control

- Modern office complexes

Advantages of Using Modern Spacer Materials in India

- Lower Energy Bills: Reducing heat transfer means less need for air conditioning.

- Increased Durability: Weather-resistant materials withstand India’s harsh UV exposure and humidity.

- Reduced Maintenance: Less condensation prevents damage and mould formation.

- Design Versatility: Suitable for curved, large, or custom glazing requirements.

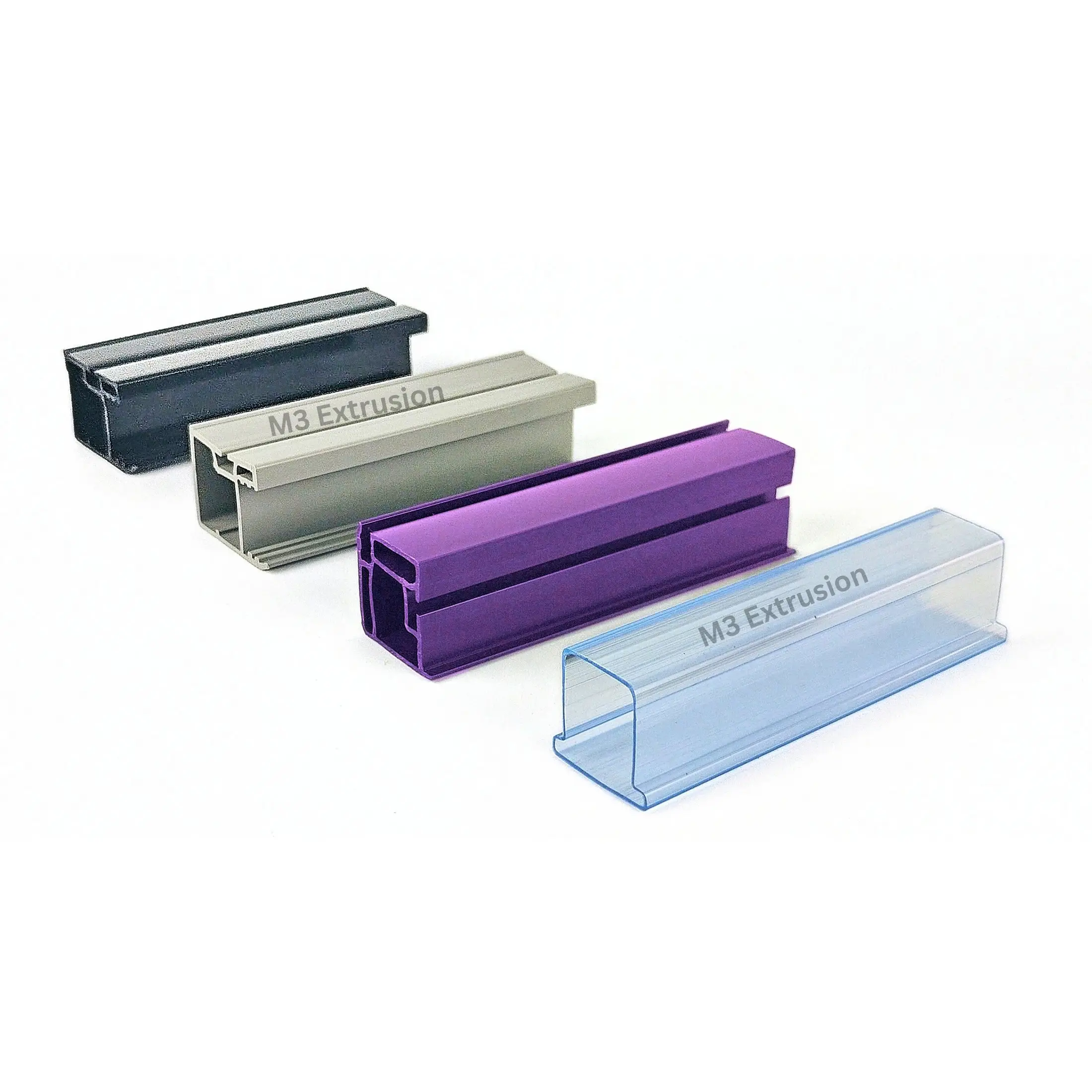

M3 Extrusion – Trusted Source for Warm Edge Spacers in India

At M3 Extrusion, we provide premium quality warm edge spacer solutions developed to meet India’s construction and architectural demands. Our spacers are designed to ensure thermal insulation, reduce energy loss, and support sustainable building projects. Whether you are a façade system supplier, glass processor, or building contractor, we offer reliable, customisable spacer options in bulk.

For product enquiries or bulk orders: visit M3 Extrusion’s location on Google.

Frequently Asked Questions (FAQs)

- Why are warm edge spacers better than aluminium spacers?

Warm edge spacers reduce heat transfer and improve energy efficiency, unlike aluminium which conducts heat easily, leading to energy loss. - Which material is most effective for warm edge spacers?

Hybrid plastics combined with stainless steel or structural foams are considered the best due to their thermal resistance and strength. - Are these spacers suitable for all parts of India?

Yes, their durability and resistance to temperature changes make them ideal for India’s varied climatic zones. - Can these spacers help reduce electricity bills in commercial buildings?

Definitely. Improved insulation means less cooling is required, lowering energy consumption and costs. - Where can I source high-quality warm edge spacers in India?

M3 Extrusion offers a range of warm edge spacers designed for Indian market needs, ensuring reliability and energy efficiency.