When industries in India look for a material that is strong, lightweight, and built to last, polycarbonate profiles often come to the front. A polycarbonate profile in India is widely used in construction, industrial design, and infrastructure projects because it offers high impact resistance, long service life, and flexibility in design. This balance of performance and reliability makes it a preferred choice for bulk buyers and manufacturers.

What Are Polycarbonate Profiles?

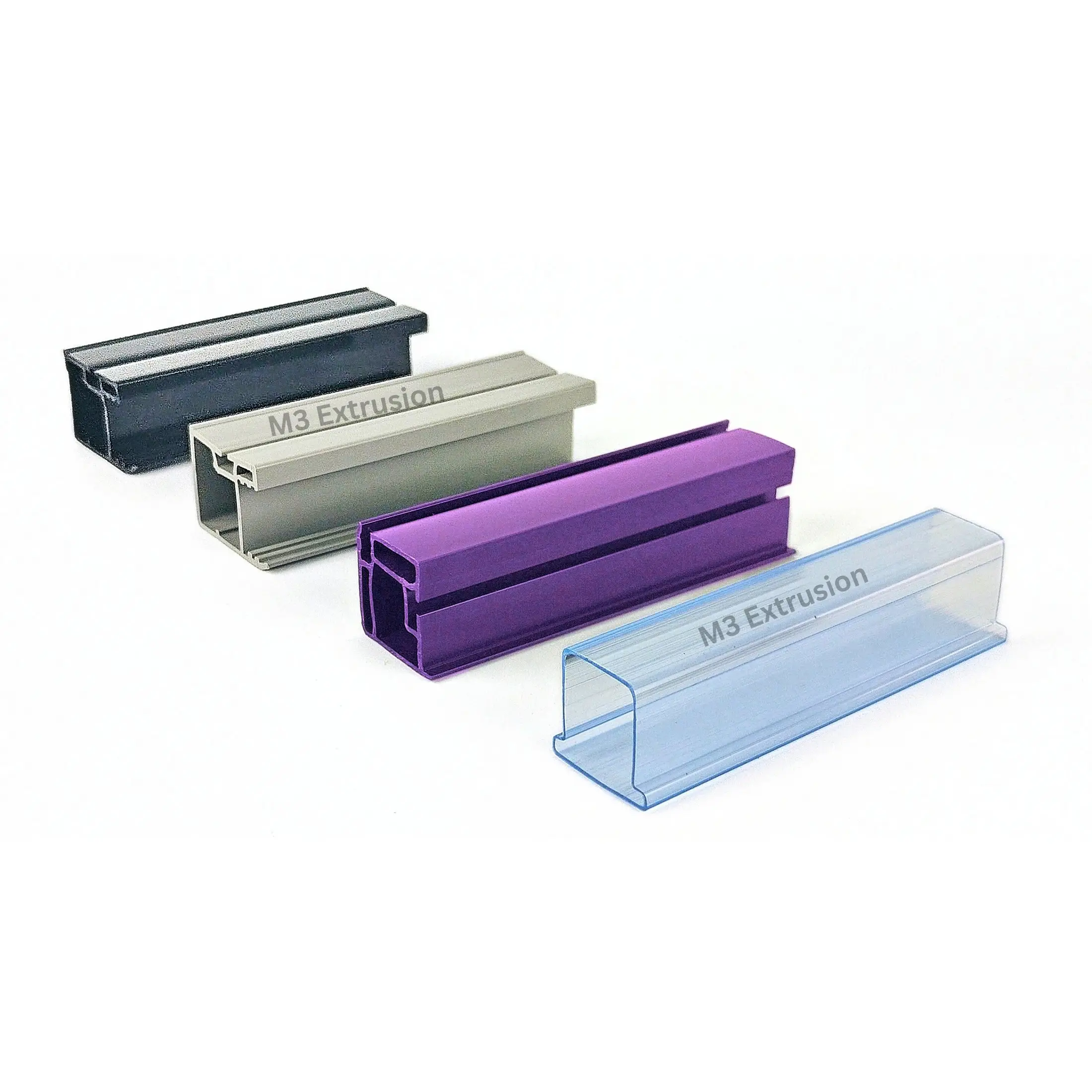

Polycarbonate profiles are shaped plastic extrusions made from polycarbonate, a thermoplastic polymer known for its toughness and clarity. These profiles can be customised into various shapes like U-channels, H-profiles, and edge trims, depending on their use.

Key characteristics include:

- High resistance to impact and pressure.

- Ability to withstand extreme temperatures.

- UV resistance, making them suitable for outdoor projects.

This combination allows businesses to rely on polycarbonate profiles for demanding applications where other materials may not perform as effectively.

Why Durability Matters for Indian Businesses

Durability is not just about strength; it is about reducing maintenance costs, ensuring safety, and supporting long-term operations. In India’s growing infrastructure and manufacturing sectors, businesses need solutions that deliver value for years without frequent replacements.

Polycarbonate profiles answer this need by offering:

- Weather protection: They do not warp, crack, or weaken under harsh sun, heavy rain, or humidity.

- Cost efficiency: Fewer replacements mean reduced operational expenses.

- Consistency in bulk supply: Manufacturers like M3 Extrusion can provide profiles in large volumes with the same quality.

Common Applications of Polycarbonate Profiles

Polycarbonate profiles are now part of multiple industries because of their versatility. Some of the most common uses include:

1. Construction and Architecture

- Roof glazing and skylights for natural lighting.

- Partition walls and curtain wall systems.

- Edge trims for panels and cladding systems.

2. Industrial and Engineering Projects

- Machine guards and protective barriers.

- Greenhouse structures where light transmission and durability are essential.

- Profiles for conveyor belts, safety shields, and framing.

3. Electrical and Signage Applications

- Cable covers and insulation parts.

- Lighting diffusers and signage frames.

- Display units that require strong yet lightweight materials.

These applications highlight why industries continue to invest in polycarbonate profiles over traditional metals or glass.

Advantages of Choosing Polycarbonate Profiles

The long-term durability of polycarbonate profiles is supported by several advantages:

- Impact resistance: 200 times stronger than glass, making it ideal for safety-critical applications.

- Lightweight: Easier to transport and install, reducing labour costs.

- Thermal stability: Maintains shape and performance under hot and cold conditions.

- Design flexibility: Can be extruded into complex shapes to suit different projects.

For businesses that require reliability in bulk, these advantages ensure consistent performance across multiple applications.

Polycarbonate Profiles in India: Meeting Market Needs

In India, industries demand cost-effective yet long-lasting solutions. Polycarbonate profiles meet these expectations by offering:

- Bulk manufacturing availability: Ensuring large projects can be supplied without delay.

- Adaptability for custom projects: Profiles can be manufactured in specific shapes and sizes.

- Compliance with safety standards: Essential for construction and industrial use.

For businesses focusing on infrastructure growth or product manufacturing, polycarbonate profiles are becoming a practical and future-ready choice.

To gain a deeper understanding of how polycarbonate profiles are applied in modern projects, For more details, see applications of polycarbonate profiles in modern projects.

Direct Answers to Common Questions

Are polycarbonate profiles durable?

Yes, they are highly durable, with resistance to impact, heat, and UV radiation. This makes them suitable for long-term use in both indoor and outdoor projects.

Why are polycarbonate profiles popular in India?

They offer a cost-effective balance of strength, flexibility, and bulk supply availability, which matches the needs of Indian industries such as construction, electrical, and agriculture.

FAQs

- What is a polycarbonate profile?

A polycarbonate profile is an extruded plastic section made from polycarbonate material. It is used in applications like roofing, partitions, machine guards, and signage because of its strength, clarity, and resistance to damage. - Where are polycarbonate profiles most commonly used?

They are widely used in construction for skylights and partitions, in industry for safety shields, and in agriculture for greenhouses. Their durability makes them suitable for both indoor and outdoor applications. - How long do polycarbonate profiles last?

On average, they last between 10 to 20 years depending on the environment. UV-protected versions are particularly resistant to weathering and are common in outdoor projects. - Can polycarbonate profiles be customised for bulk orders?

Yes, manufacturers like M3 Extrusion provide bulk orders and can customise profiles into specific shapes such as U, H, or L channels to meet project needs. - Why should businesses choose polycarbonate profiles in India?

Businesses in India choose polycarbonate profiles because they combine high durability, cost efficiency, and availability in bulk. This makes them a dependable material for large-scale projects.

Conclusion

Polycarbonate profiles offer a practical balance of durability, flexibility, and long-term value. Their ability to perform under demanding conditions makes them an excellent choice for industries across India. From construction to electrical systems and agriculture, businesses continue to rely on polycarbonate profiles for projects where strength and reliability matter most.