Walk through any modern factory, warehouse, or commercial building in India, and you will notice a quiet shift happening. Components once made from aluminium or steel are increasingly being replaced with rigid plastic profiles. From cable management to window systems, rigid PVC extrusion has become the preferred choice for businesses that want durability without unnecessary cost or maintenance.

Having worked closely with industrial buyers and project teams, I have seen this transition first-hand. The reasons go far beyond price. Performance, adaptability, and long-term reliability play a bigger role than many realise.

What Is Rigid PVC Extrusion

Rigid PVC extrusion is a manufacturing process where polyvinyl chloride is shaped into fixed-profile sections using heat and pressure. Unlike flexible PVC, rigid PVC maintains its shape, strength, and dimensional stability even under continuous use.

These profiles are widely used in:

- Building and construction components

- Electrical and cable management systems

- Industrial framing and protection profiles

- Window, door, and partition systems

For Indian industries that operate in varied climates and demanding environments, this consistency matters.

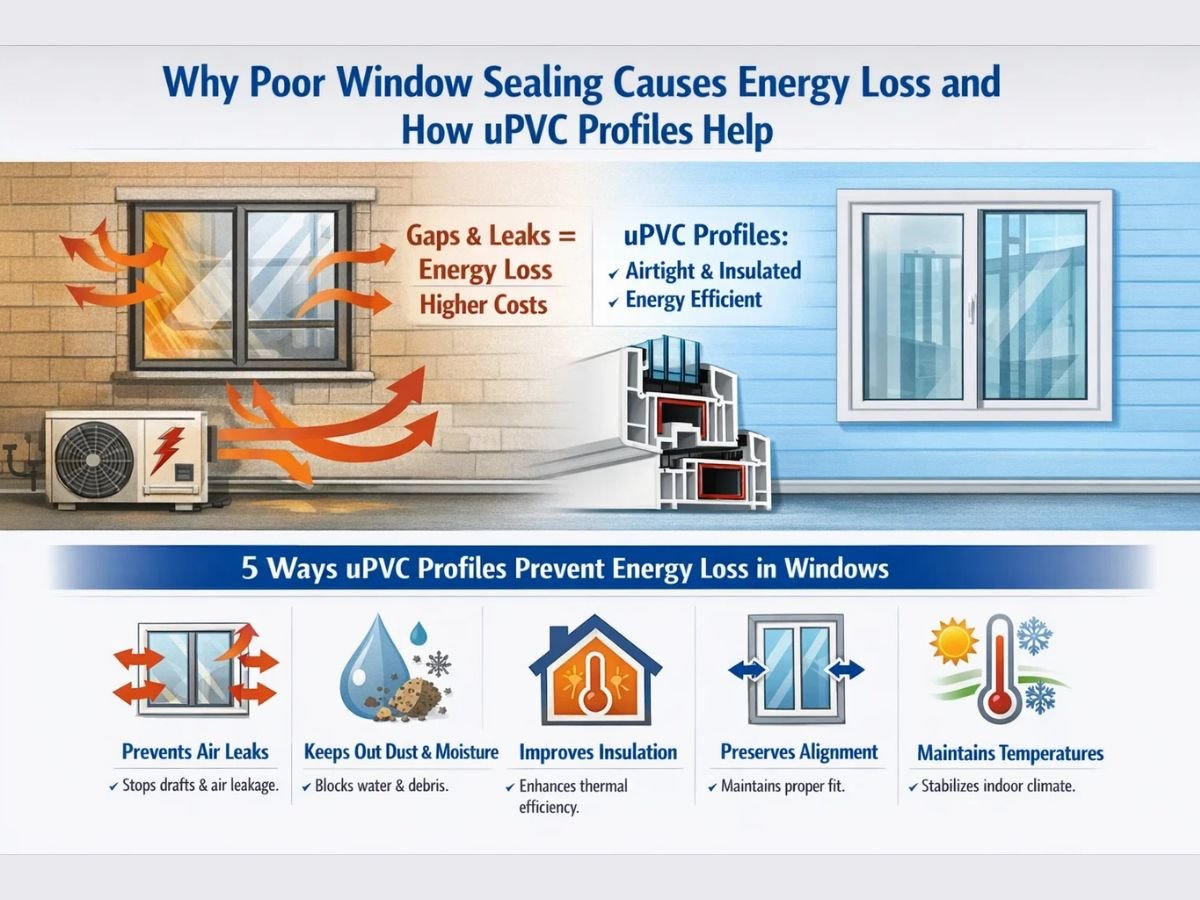

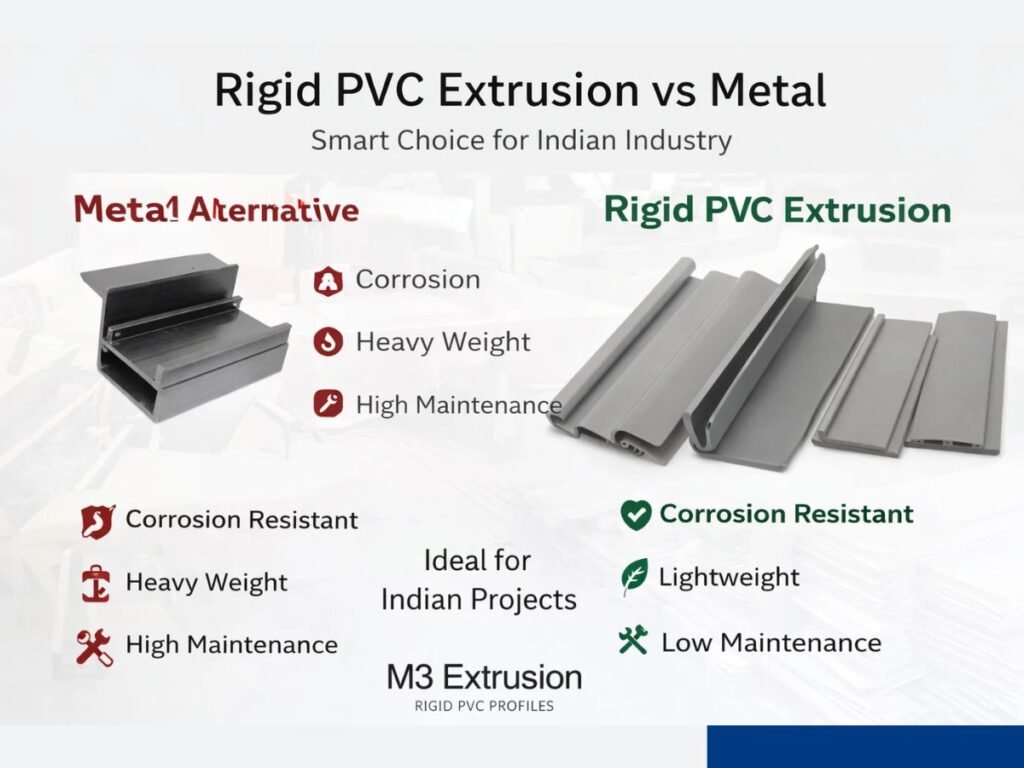

Why Metal Alternatives Are Losing Preference

Metal profiles have served industries well for decades. However, modern projects demand materials that reduce complexity without compromising performance.

Common challenges with metal profiles include:

- Corrosion in humid or coastal regions

- Higher weight, increasing transport and installation effort

- Rising raw material and fabrication costs

- Ongoing maintenance and surface treatment needs

These limitations have pushed businesses to explore smarter alternatives, where rigid PVC extrusion fits naturally.

Key Reasons Businesses Prefer Rigid PVC Extrusion

1. Corrosion Resistance in Indian Conditions

One of the biggest advantages of rigid PVC is that it does not rust. In industrial zones with moisture, chemicals, or pollution, metal components often degrade faster than expected.

Rigid PVC profiles:

- Remain stable in humid and coastal regions

- Resist chemical exposure in factories and warehouses

- Do not require anti-corrosion coatings

This alone reduces long-term maintenance costs significantly.

2. Lightweight but Structurally Reliable

Rigid PVC may be lighter than metal, but it is far from weak. When designed correctly, these profiles offer excellent load-bearing and impact resistance for non-structural applications.

Benefits include:

- Easier handling on-site

- Faster installation with less labour

- Lower transportation costs

For large projects, this weight reduction translates into real operational savings.

3. Cost Efficiency Across the Lifecycle

While initial material cost matters, smart buyers look at total lifecycle cost. Rigid PVC extrusion often proves more economical over time.

It helps businesses by:

- Reducing fabrication and finishing steps

- Eliminating repainting or surface treatment

- Minimising replacement frequency

Over years of use, rigid PVC profiles deliver better value than many metal alternatives.

Understanding Where Rigid Plastic Profiles Fit in Buildings

To make the right material choice, it helps to clearly understand where rigid plastic profiles fit in buildings. These profiles are not meant to replace heavy structural steel. Instead, they excel in functional and finishing applications.

Common building uses include:

- Window and door reinforcement covers

- Cable trunking and conduit systems

- Partition trims and protective edges

- Cladding support and spacer profiles

In these areas, rigid PVC extrusion offers reliability without overengineering the solution.

For more insights, check out our guide on Where Rigid Plastic Profiles Are Commonly Used in Buildings.

Design Flexibility That Metal Cannot Match

Custom Shapes and Consistent Output

Extrusion allows rigid PVC profiles to be manufactured in complex cross-sections that are difficult or costly with metal. This opens new design possibilities for architects and engineers.

With rigid PVC extrusion, businesses can achieve:

- Precise dimensions with tight tolerances

- Integrated channels, slots, and fixing points

- Smooth surface finishes without secondary processing

This flexibility supports customised solutions for project-based requirements.

Colour and Finish Options

Unlike metal, rigid PVC profiles can be produced in consistent colours without painting. This improves appearance and reduces finishing time.

Common advantages:

- UV-stable colours for long-term appearance

- Matte or glossy finishes as required

- Easy branding or identification through colour coding

This is especially useful in commercial interiors and visible installations.

Performance Advantages in Daily Industrial Use

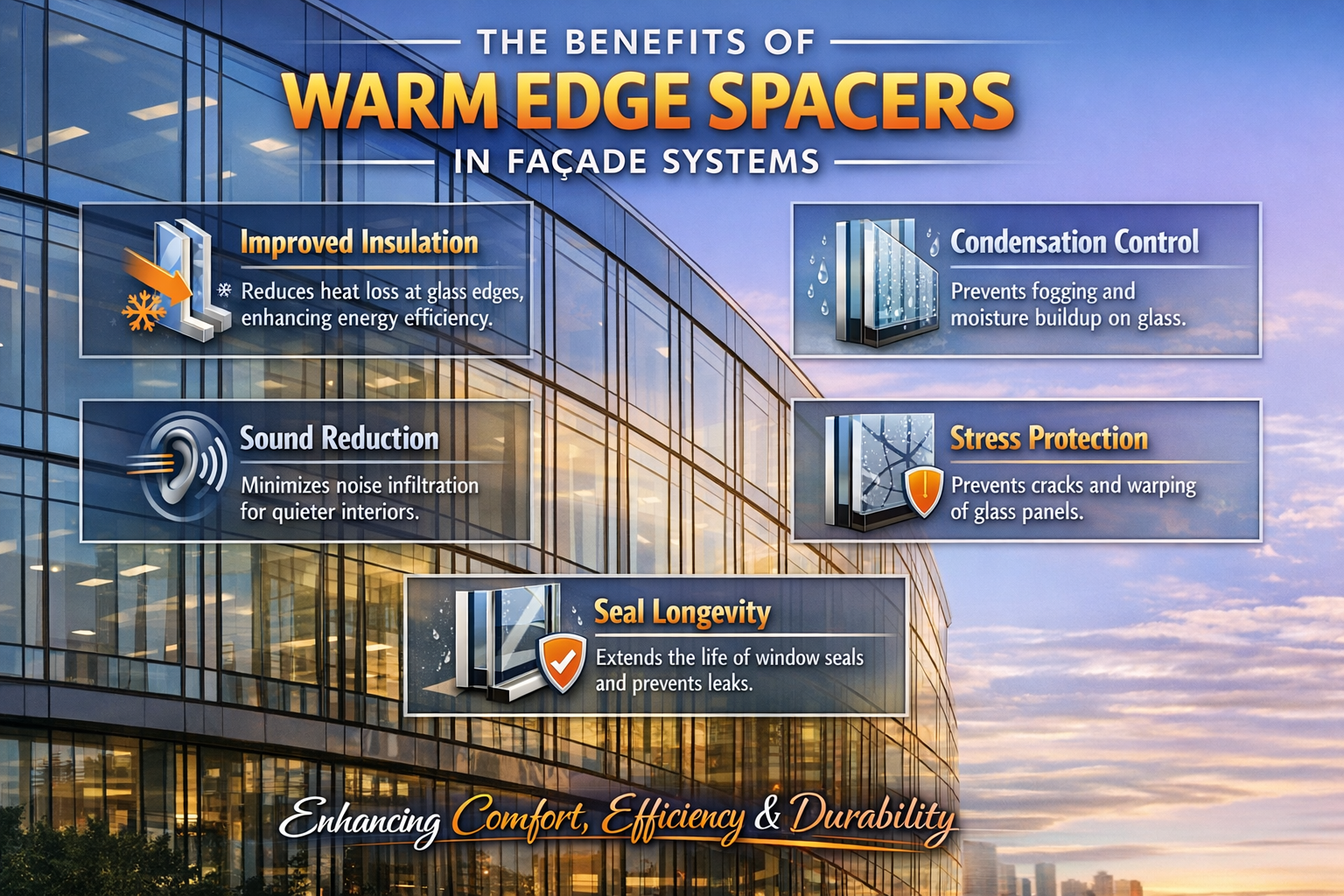

Electrical and Thermal Insulation

Rigid PVC naturally resists electrical conductivity and reduces heat transfer. This makes it safer for many applications compared to metal.

It is commonly chosen for:

- Electrical enclosures and trunking

- Spacer and separation profiles

- Areas where thermal bridging must be minimised

For Indian industries focused on safety and efficiency, this is a key advantage.

Noise and Vibration Control

Metal components can amplify noise and vibration in industrial environments. Rigid PVC helps dampen these effects.

Practical benefits include:

- Reduced operational noise

- Lower vibration transfer to surrounding structures

- Improved working conditions in factories

This often goes unnoticed until businesses experience the difference.

Sustainability and Material Efficiency

Rigid PVC extrusion supports responsible material use when sourced and manufactured correctly. Profiles are produced with minimal waste, and off-cuts can often be recycled.

From a sustainability perspective:

- Longer service life reduces replacement demand

- Lower weight cuts transport-related emissions

- Precise extrusion reduces raw material wastage

These factors align well with modern construction and industrial standards.

Why Indian Businesses Are Making the Shift

Across manufacturing, infrastructure, and building projects, Indian businesses are prioritising materials that simplify operations without compromising quality.

Rigid PVC extrusion meets this need by offering:

- Consistent performance in varied climates

- Lower long-term cost and maintenance

- Design adaptability for custom applications

At M3 Extrusion, we have seen increasing demand from clients who initially used metal profiles but switched after experiencing the operational benefits of rigid PVC solutions.

Key Takeaway for Decision Makers

Rigid PVC extrusion is not about replacing metal everywhere. It is about using the right material in the right application. For non-structural profiles where durability, consistency, and efficiency matter, rigid PVC often delivers better results with fewer complications.

When businesses understand application needs clearly, the choice becomes straightforward.

Frequently Asked Questions

Is rigid PVC extrusion strong enough for industrial use

Rigid PVC extrusion is designed for non-structural industrial applications. It offers excellent dimensional stability, impact resistance, and load-handling capability for profiles used in cable management, protection systems, and building components, making it suitable for demanding industrial environments.

How does rigid PVC compare to aluminium in long-term cost

While aluminium may appear strong initially, rigid PVC often proves more cost-effective over time. It requires no corrosion protection, less maintenance, and simpler installation, which reduces overall lifecycle costs for businesses operating at scale.

Can rigid PVC profiles handle Indian weather conditions

Yes. Rigid PVC extrusion performs well across varied Indian climates, including high humidity, heat, and pollution. Properly formulated profiles resist warping, cracking, and surface degradation, making them reliable for indoor and semi-outdoor applications.

Are rigid PVC profiles customisable for projects

Rigid PVC extrusion allows high customisation. Profiles can be produced in specific shapes, sizes, and colours to match project requirements, making them ideal for project-based construction and industrial applications where standard sections are not suitable.

Is rigid PVC safe for electrical applications

Rigid PVC is naturally non-conductive and offers good thermal insulation. This makes it a safe choice for electrical trunking, enclosures, and separation profiles where reducing electrical and heat transfer risks is important.

Where should metal still be preferred over rigid PVC

Metal remains the better option for heavy structural load-bearing components or areas exposed to extreme mechanical stress. Rigid PVC extrusion is best suited for functional, protective, and finishing profiles where strength, stability, and efficiency are required without excessive weight.

Check related articles for more insights: