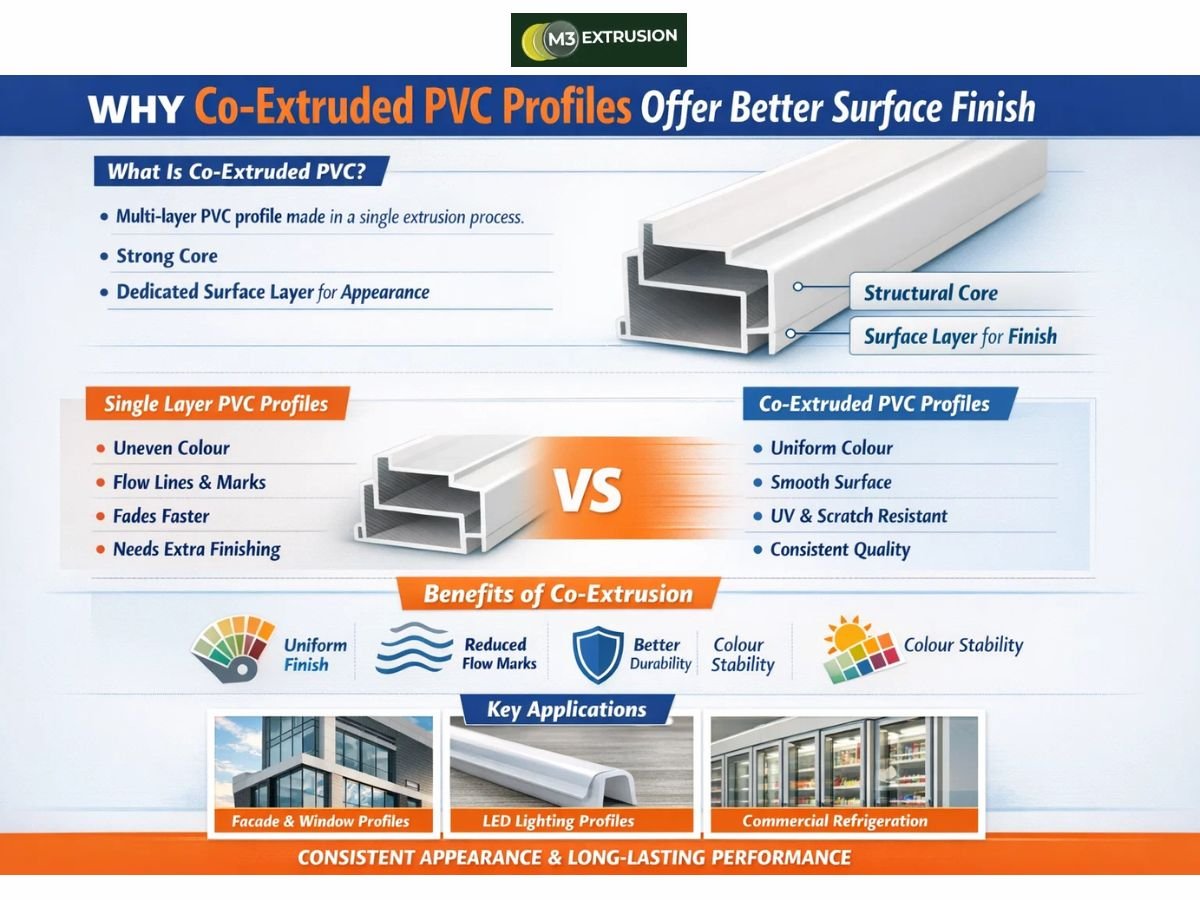

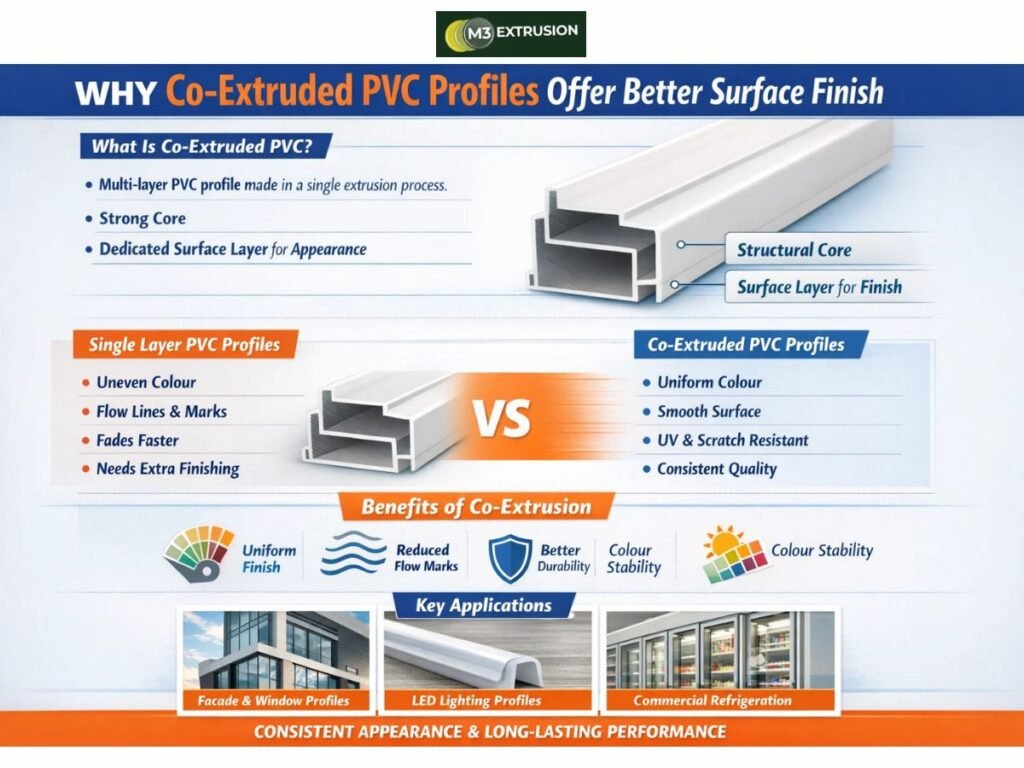

Anyone who has worked with plastic profiles knows this problem well. On paper, the design looks perfect. Once installed, the surface tells a different story. Uneven colour, fine flow marks, or a finish that looks dull under light. These issues usually do not come from poor installation. They come from how the profile was made.

This is one of the main reasons co-extruded PVC in India has become the preferred choice for applications where appearance matters as much as performance. From façade systems to LED lighting and refrigeration components, co-extrusion delivers a level of surface control that single layer profiles struggle to achieve.

What Makes Surface Finish So Important?

Surface finish is not just about looks. In industrial and commercial products, it affects:

- Perceived quality of the final product

- Ease of cleaning and maintenance

- Long-term colour stability

- Customer acceptance in visible installations

A poor finish can lead to rejections even if the profile is structurally sound.

Understanding Co-Extruded PVC Profiles

Co-extruded PVC profiles are produced by extruding two or more PVC compounds together in a single process. Each layer serves a specific role.

Simple explanation:

One layer handles strength. Another layer handles appearance.

Because these layers are formed together, the finished profile behaves like one solid unit, not a surface coating added later.

This manufacturing approach gives far greater control over how the outer surface looks and performs.

Why Single-Layer Profiles Often Show Finish Issues

Single material profiles are forced to do too much at once. The same compound must provide strength, colour, UV resistance, and surface smoothness.

In real production environments, this leads to:

- Inconsistent gloss across batches

- Surface flow lines from extrusion pressure

- Faster fading in visible areas

- Higher dependency on post processing

These issues become more visible as production volumes increase.

How Co-Extrusion Improves Surface Finish

Dedicated Surface Layer

In co-extrusion, the outer layer is designed specifically for surface quality. This layer can be adjusted independently without affecting the structural core.

Benefits include:

- Uniform colour distribution

- Controlled gloss or matte finish

- Reduced extrusion marks

- Better resistance to scratches

This is why co-extruded PVC profiles often look cleaner straight off the line.

No Need for Secondary Finishing

Painted or laminated finishes add cost and risk. Peeling, uneven adhesion, and colour mismatch are common problems.

With co-extruded PVC in India, the surface finish is built into the profile during extrusion. This eliminates additional steps and reduces variation across production runs.

Consistency Across Long Production Cycles

Surface finish issues often appear when a project moves from samples to mass production.

Co-extrusion helps maintain:

- Colour consistency from batch to batch

- Stable surface texture across long lengths

- Predictable visual output over time

This matters for OEMs supplying large projects where visual variation can lead to rework or rejection.

Improving Product Durability With Co-Extruded PVC

Surface quality and durability are closely linked. A surface that degrades quickly will never look good for long.

This is where improving product durability with co-extruded PVC becomes a practical advantage.

By using a wear resistant or UV stable outer layer, the profile:

- Resists surface cracking

- Maintains colour under light exposure

- Handles repeated contact without visible damage

This approach is commonly used in refrigerator door profiles, sliding components, and LED housings where both finish and durability matter.

Real-World Applications Where Finish Matters

Façade and Window Profiles

Visible architectural elements demand clean lines and stable colour. Co-extruded PVC helps maintain surface appearance even under sunlight and temperature changes.

LED Lighting Profiles

Uneven surfaces affect light diffusion. A smooth, controlled outer layer ensures consistent light output and a clean look when lights are off.

Commercial Refrigeration

Door frames and trims are seen up close every day. Surface defects are immediately noticeable. Co-extrusion helps maintain a professional finish over long usage cycles.

Manufacturing Control and Design Flexibility

Another advantage of co-extrusion is flexibility during design development.

Manufacturers can adjust:

- Surface layer thickness

- Colour shade without changing core material

- Surface texture for specific applications

This allows fine-tuning without redesigning the entire profile.

M3 Extrusion works with industrial customers to develop co-extruded PVC profiles where surface finish requirements are defined early, helping avoid downstream appearance issues during mass production.

How to Decide if Co-Extrusion Is the Right Choice

Ask these practical questions before finalising your profile design:

- Will the profile be visible in the final installation?

- Is colour consistency important across large quantities?

- Does the surface face wear, cleaning, or handling?

- Are finishing defects causing rejections today?

If the answer is yes to most of these, co-extrusion is usually the safer long-term option.

Key Takeaways for Buyers and Designers

- Co-extrusion separates surface quality from structural performance

- Surface finish becomes more predictable and stable

- Durability improves without added processing

- Visual consistency is easier to maintain at scale

For manufacturers sourcing co-extruded PVC in India, the real value lies in fewer finish related issues and better control over final appearance.

Frequently Asked Questions

What is co-extruded PVC, and why is it used?

Co-extruded PVC is a multi-layer plastic profile made in one extrusion process. It is used to combine strength and surface quality in a single profile. Each layer performs a specific function, resulting in better finish, durability, and consistency compared to single material profiles.

How does co-extrusion improve surface finish?

Co-extrusion allows a dedicated outer layer designed only for appearance. This layer provides uniform colour, smoother texture, and reduced extrusion marks. Because it is formed during extrusion, the finish remains consistent across batches without secondary processing.

Is co-extruded PVC suitable for visible applications?

Yes, co-extruded PVC is ideal for visible applications such as façade profiles, window systems, LED housings, and commercial refrigeration components. The controlled surface layer helps maintain a clean and uniform appearance even after long-term use.

Does co-extruded PVC cost more than regular PVC profiles?

Initial tooling may be slightly higher, but overall costs are often balanced out. Co-extrusion reduces the need for painting or laminating and lowers rejection rates. Over long production runs, it usually results in better cost efficiency.

Can co-extruded PVC profiles be customised?

Co-extruded PVC profiles can be customised in shape, colour, and layer thickness. This makes them suitable for OEM and project based manufacturing where surface finish, durability, and consistency are critical requirements.

How does co-extruded PVC improve durability?

Durability improves by using a tougher or UV-stable outer layer while keeping a rigid core. This combination protects the surface from wear, fading, and cracking, helping the profile maintain both appearance and performance over time.

Check related articles for more insights: