In modern construction and industrial applications, sealing plays a vital role in protecting buildings, machinery, and products from external factors like moisture, dust, and temperature changes. A flexible PVC profile in India is often the preferred choice for these sealing needs, as it combines durability, adaptability, and cost-effectiveness in one solution. For manufacturers working on bulk requirements or order-based production, these profiles are practical and reliable.

The Importance of Sealing in Industrial and Construction Projects

Whether it is a residential building, a commercial complex, or an industrial plant, sealing is necessary to:

- Prevent water leakage and dust intrusion.

- Maintain insulation and reduce energy loss.

- Enhance the life of windows, doors, and other structures.

Without effective sealing, structures face wear and tear faster, leading to higher maintenance costs. That is why selecting the right sealing material is a priority for manufacturers and builders.

What Makes Flexible PVC Profiles Ideal for Sealing?

Polyvinyl chloride (PVC) is widely used in extrusion because of its versatility. When made into flexible profiles, it offers several advantages over traditional sealing materials like rubber or metal.

1. Adaptability

Flexible PVC can be shaped into a variety of profiles, making it suitable for different sealing applications such as window frames, doors, and machinery enclosures.

2. Durability

PVC profiles are resistant to weather conditions, UV radiation, and chemicals. This ensures long service life even in demanding environments.

3. Cost Efficiency

Compared with rubber or aluminium sealing strips, flexible PVC is more affordable to produce in bulk, making it an economical choice for large-scale projects.

Key Benefits of Flexible PVC Profiles in Sealing Solutions

Better Weather Resistance

Flexible PVC profiles can withstand hot summers, heavy rains, and cold winters. They maintain their flexibility without cracking or shrinking, which helps create a long-lasting seal.

Reduced Energy Costs

By preventing air leakage around windows and doors, these profiles help maintain stable indoor temperatures. This leads to reduced energy consumption for heating and cooling.

Ease of Installation

Manufacturers and contractors value materials that are easy to handle. Flexible PVC seals can be quickly installed, cut, or adjusted on-site, saving both time and labour costs.

Low Maintenance

Once fitted, these profiles require minimal maintenance. They do not corrode, attract mould, or lose shape easily, which reduces replacement needs.

Applications Across Industries

The versatility of flexible PVC profiles makes them useful in a wide range of sectors:

- Construction: Used in doors, windows, and partitions for effective sealing.

- Automotive: Applied in vehicle doors and glass to prevent vibration, dust, and noise.

- Electrical Enclosures: Protects sensitive equipment from dust and moisture.

- Furniture and Interiors: Helps in providing smooth finishes and sealing edges.

This wide applicability explains why many manufacturers prefer PVC profiles over traditional sealing materials.

Why Manufacturers Prefer Flexible PVC for Bulk Orders

For industries that require sealing solutions in large volumes, flexible PVC offers a practical balance between performance and cost. Manufacturers often choose it because:

- It can be extruded in custom shapes and sizes to meet specific project requirements.

- Bulk supply ensures consistency in quality across all units.

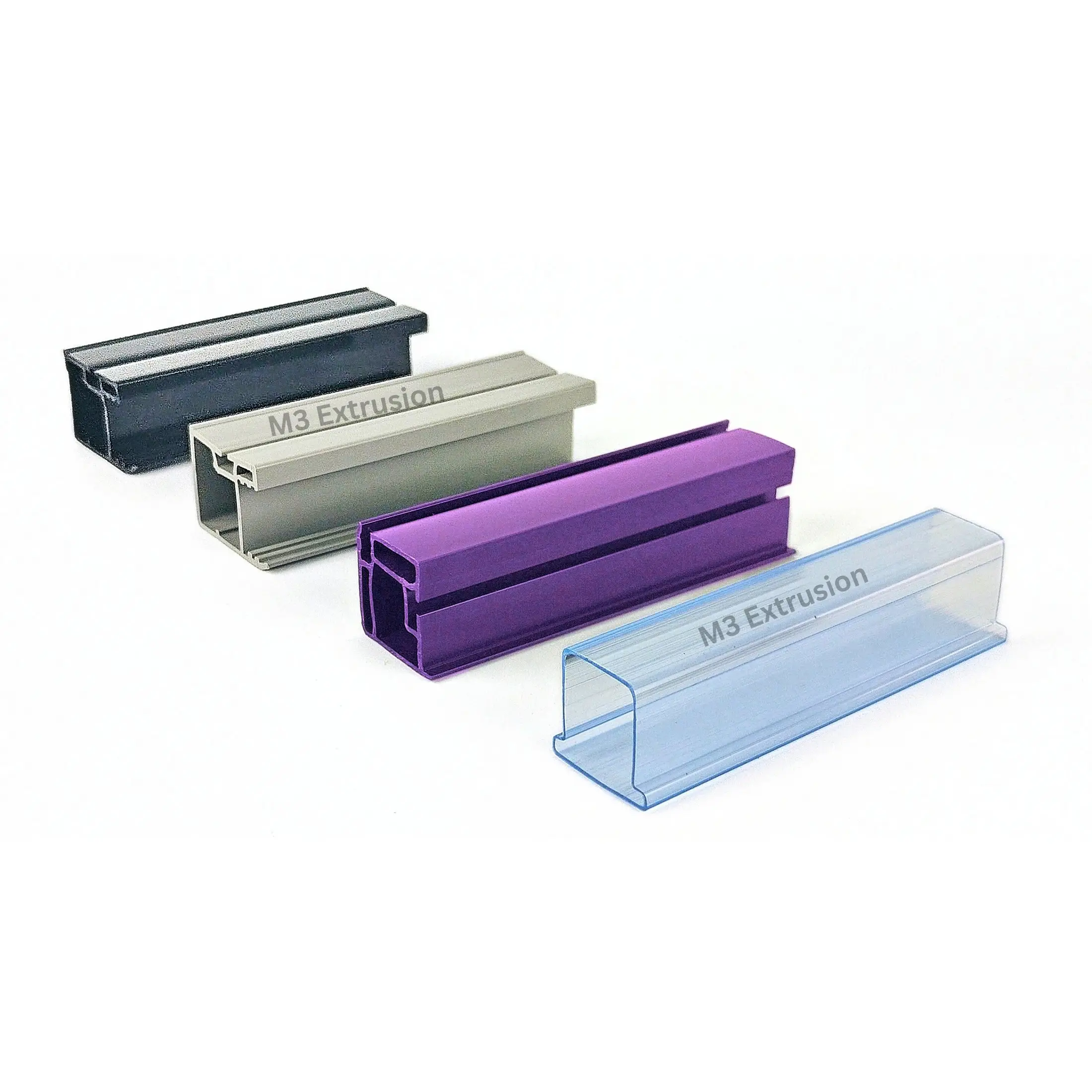

- Order-based manufacturing allows flexibility in colour, hardness, and profile design.

Suppliers like M3 Extrusion work closely with industries to deliver bulk PVC profiles that meet the demands of large construction and industrial projects.

Flexible PVC vs. Other Sealing Materials

To better understand the cost and performance advantages, let’s compare flexible PVC profiles with other common sealing materials:

- Rubber Seals: Rubber provides flexibility but tends to degrade faster in extreme conditions. PVC offers similar flexibility with greater durability.

- Aluminium Strips: Aluminium is strong but lacks flexibility and insulation properties. PVC is lightweight, adaptable, and thermally efficient.

- Foam Seals: Foam seals are easy to install but wear out quickly. PVC provides a more durable alternative without frequent replacement.

This balance of flexibility, durability, and cost savings makes PVC a clear winner for many manufacturers.

Innovations in Flexible PVC Profiles

The industry is not standing still. Manufacturers are now using advanced extrusion techniques to improve the quality and sustainability of PVC sealing profiles. Some of these innovations include:

- Reinforced PVC blends for added strength.

- Eco-friendly compounds with reduced environmental impact.

- Improved flexibility for applications that require tight sealing without damage.

For businesses seeking high-quality PVC profiles in bulk, these advancements ensure that sealing solutions are not only cost-effective but also aligned with modern sustainability practices.

FAQs on Flexible PVC Profiles

1. Why are flexible PVC profiles used for sealing?

They provide a durable and adaptable seal that protects against dust, water, and temperature changes while being affordable for bulk applications.

2. Are flexible PVC profiles better than rubber seals?

Yes, PVC profiles last longer under varying weather conditions, require less maintenance, and are cost-effective for large-scale use.

3. Can flexible PVC be customised for specific projects?

Absolutely. Profiles can be manufactured in different sizes, shapes, and hardness levels to match project needs.

4. Do flexible PVC profiles support energy efficiency?

Yes, by preventing air leakage, they help maintain stable indoor temperatures, reducing heating and cooling costs.

5. How do manufacturers ensure consistent quality in bulk orders?

Suppliers use advanced extrusion processes and quality checks to ensure every batch maintains the required specifications and durability.

Conclusion

Flexible PVC profiles have become a preferred choice for sealing solutions across industries because of their adaptability, durability, and cost efficiency. They help reduce energy loss, cut maintenance costs, and offer a practical option for manufacturers who need reliable sealing in bulk. With ongoing innovations in extrusion and material design, PVC sealing profiles continue to prove their value in both construction and industrial applications.