In the growing Indian manufacturing sector, the demand for materials that offer both performance and affordability is increasing. Rigid PVC profiles have emerged as a preferred solution for industries ranging from construction to electrical and industrial applications. These profiles provide not only long-lasting durability but also significant cost advantages over traditional materials like wood, aluminium, and steel.

What Makes Rigid PVC Profiles Economical?

1. Affordable Raw Material

PVC is widely available and less expensive compared to metals or engineered wood products. The abundance of PVC as a raw material allows manufacturers to produce rigid profiles at lower costs, making them budget-friendly for large-scale production.

2. Lower Manufacturing and Processing Costs

Rigid PVC profiles require simpler manufacturing processes compared to metals, such as extrusion, which consumes less energy and requires minimal post-processing. This reduces production time, labour costs, and overall operational expenses.

3. Minimal Maintenance Requirements

Unlike wood or metal, rigid PVC profiles do not rust, corrode, or suffer from termite attacks. Their inherent resistance to moisture, chemicals, and UV radiation means they require little to no maintenance once installed, reducing long-term costs for end users.

4. Long Service Life

PVC’s durability ensures that profiles remain functional and effective for years without degradation. This extended lifespan reduces the need for frequent replacements, saving costs on both material and labour.

5. Lightweight and Easy to Install

Rigid PVC profiles are lighter than metal or wood alternatives, reducing transportation and handling costs. Their ease of installation also minimises labour time and effort, further lowering project expenses.

6. Resistance to Environmental Factors

Indian climates range from humid coastal areas to dry interiors. Rigid PVC profiles are designed to perform consistently across these varying conditions. Their resistance to weathering, UV radiation, and moisture makes them a practical long-term investment.

Advantages for Indian Manufacturers

1. Versatility Across Industries

From construction to electronics and automotive industries, the adaptability of rigid PVC profiles allows manufacturers to cater to a wide range of market demands without requiring different raw materials or processing techniques. They can be easily used for window frames, cable trunking, door profiles, partition panels, and insulation covers.

2. Customisation Opportunities

Manufacturers in India can customise rigid PVC profiles in terms of size, shape, thickness, and colour to meet specific project requirements. This flexibility eliminates the need for costly modifications or specialised materials, offering efficiency in both small and large-scale production runs.

3. Eco-Friendly and Recyclable

As environmental regulations tighten in India, rigid PVC profiles offer the benefit of recyclability, helping manufacturers meet sustainability targets while also saving on waste management costs. Using recycled PVC further lowers production costs, making the entire supply chain more economical.

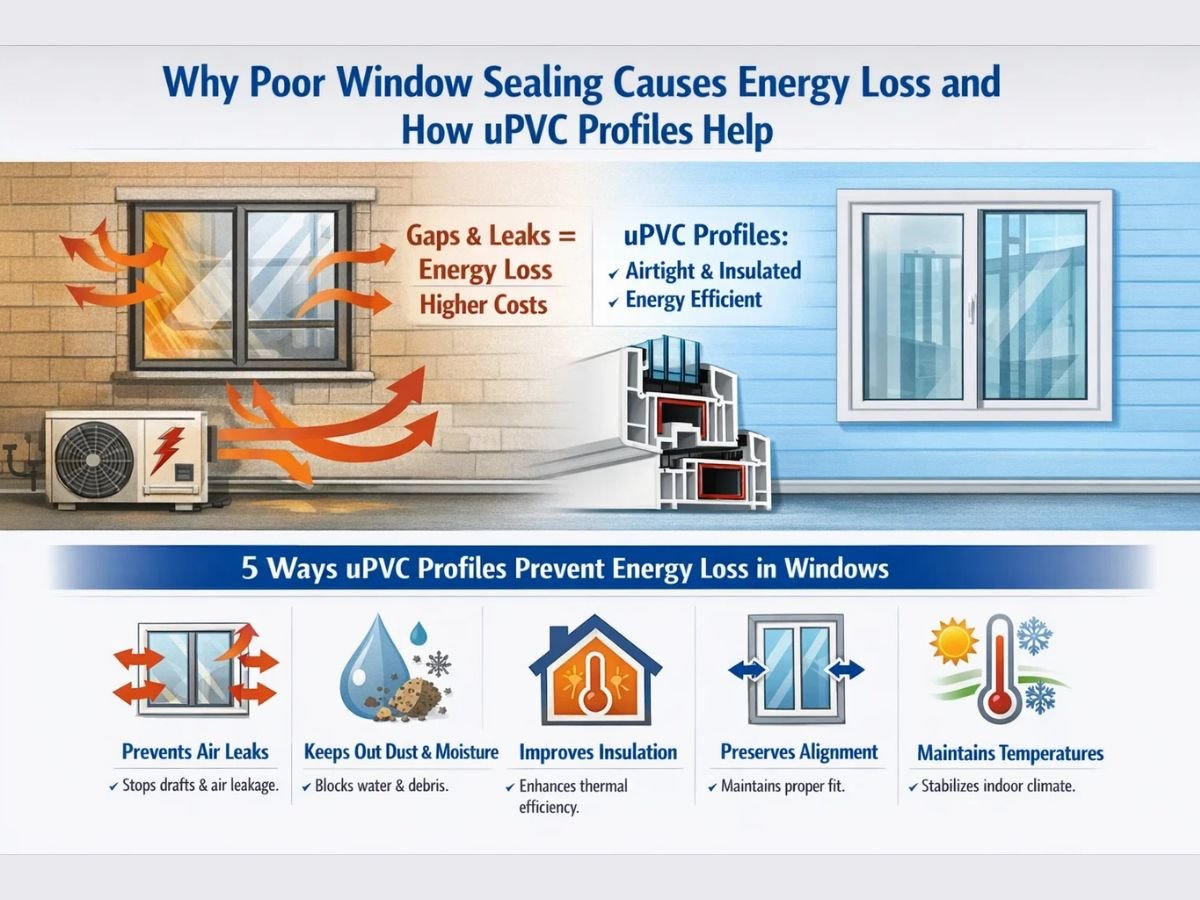

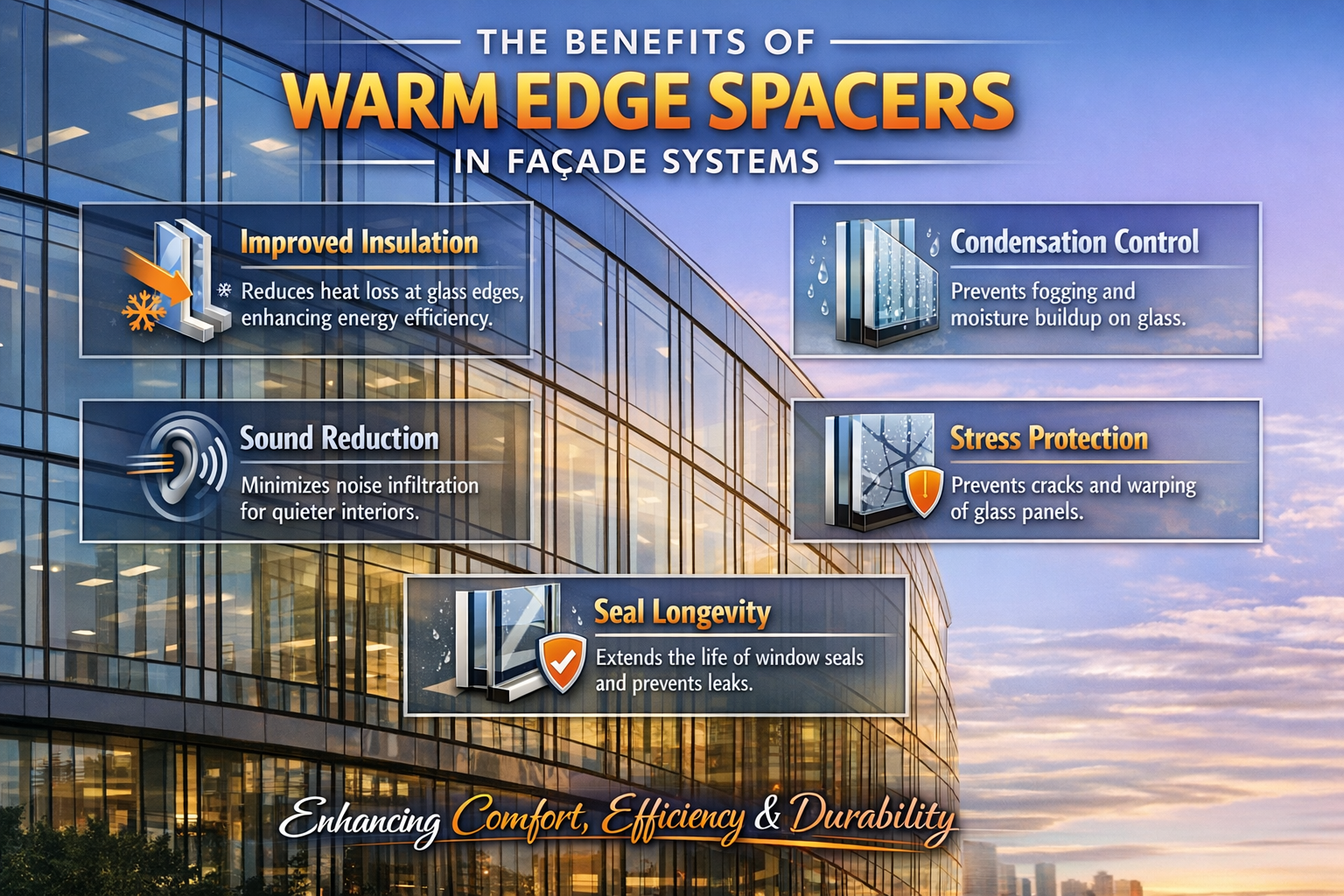

4. Suitable for Smart and Modern Construction

With India’s shift towards smart cities and modern infrastructure, the need for energy-efficient, sustainable, and durable materials is rising. Rigid PVC profiles meet these requirements perfectly by offering thermal insulation, soundproofing options, and compatibility with modern construction techniques.

5. Excellent Performance in Diverse Applications

Apart from building and construction, rigid PVC profiles are also being adopted in the fabrication of control panels, industrial equipment housings, and hygienic wall cladding in food processing units — areas where metal alternatives would be too costly or prone to corrosion.

To understand how rigid PVC profiles improve efficiency and sustainability in building, visit our detailed guide:

👉 How Rigid PVC Profiles Improve Efficiency and Sustainability in Building

For additional insights into where rigid PVC profiles are applied across India’s construction sector, explore:

👉 Top Applications of Rigid PVC Profiles in the Indian Construction Industry

M3 Extrusion – Reliable Supplier of Rigid PVC Profiles in India

At M3 Extrusion, we specialise in producing high-quality rigid PVC profiles for bulk orders across various industries in India. Our profiles are designed to offer cost-effective solutions without compromising on strength, durability, or design flexibility. Whether you need profiles for windows, cable management, or industrial components, we provide precise, reliable, and timely delivery to meet your business needs.

We cater to both large and small businesses looking for consistent quality and cost savings. Our customisation options ensure that manufacturers across sectors get exactly what they need without overpaying for unnecessary features.

For bulk enquiries and product details: visit M3 Extrusion’s location on Google.

Frequently Asked Questions (FAQs)

- Are rigid PVC profiles cheaper than aluminium alternatives?

Yes, rigid PVC profiles are generally more affordable than aluminium, both in terms of material costs and processing expenses. - Can rigid PVC profiles reduce installation costs?

Absolutely. Their lightweight nature makes handling and installation easier and faster, leading to reduced labour costs. - Do rigid PVC profiles support sustainable manufacturing?

Yes, they are recyclable and contribute to eco-friendly production, helping manufacturers meet environmental standards. - Are these profiles suitable for high-volume production?

Definitely. Rigid PVC profiles are ideal for bulk production runs due to their consistent quality and cost-effectiveness. - Where can manufacturers buy bulk rigid PVC profiles in India?

M3 Extrusion offers reliable and customisable rigid PVC profiles for various industrial and commercial needs across India. - What industries can benefit from rigid PVC profiles?

Industries like construction, electrical, automotive, and industrial equipment manufacturing extensively use rigid PVC profiles for their durability, flexibility, and cost benefits. - Can rigid PVC profiles withstand India’s diverse weather conditions?

Yes, rigid PVC profiles are designed to resist UV rays, humidity, and corrosion, making them suitable for use in various climatic zones across India.