In today’s construction and glass processing industry, energy performance is not just a bonus, it is a necessity. The focus has shifted from just building aesthetically pleasing structures to creating energy-efficient, climate-conscious spaces. One component playing a significant role in this shift is the humble spacer profile used in insulated glass units. While aluminium has been a long-time standard, warm edge spacers are now replacing it as the preferred choice for modern window systems.

Across residential and commercial buildings, thermal comfort, durability and long-term cost savings are key. In line with these requirements, the use of warm edge spacer in India has seen a noticeable rise. Architects, window system suppliers and IGU manufacturers are turning to modern materials that reduce energy transfer, especially in climate-sensitive zones.

Understanding the Role of Spacer Profiles

A spacer profile separates the panes of glass in an insulated glass unit and seals the air or gas-filled space in between. It also provides structural integrity and ensures that moisture does not enter the cavity. For many years, aluminium was widely used for this purpose due to its strength and availability.

However, aluminium is a high conductor of heat. When used in windows, it causes a cold bridge effect, allowing heat to escape easily and creating condensation around the window edge. This leads to energy loss and can shorten the lifespan of the window system.

Warm edge spacers, made from materials such as thermoplastic, PVC, stainless steel hybrids or composite polymers, offer a better alternative. These materials are designed to insulate the edge of the glass unit, reducing thermal bridging and keeping the interior environment more stable.

Why Aluminium Is Losing Ground to Warm Edge Technology

The performance gap between aluminium spacers and warm edge spacers is significant. More industry professionals are moving to warm edge spacers for the following reasons:

Improved insulation value

Warm edge materials do not conduct heat like aluminium. This means they keep the edges of the window warmer, reducing the overall U-value of the glass unit and improving thermal performance.

Less condensation

With better insulation, there is a lower risk of condensation forming on the inside edges of the window. This helps maintain clarity, protects the frame, and avoids moisture-related damage.

Energy cost savings

By reducing heat loss, warm edge spacers contribute to overall energy savings. Windows fitted with these spacers support lower heating and cooling needs, which makes them ideal for green buildings.

Longer IGU lifespan

Because these spacers are more compatible with the thermal expansion of glass, they reduce stress on the sealant, resulting in longer-lasting sealed units.

Flexible design options

Many warm edge spacer materials allow for colour matching, surface texture options and compatibility with automated IGU production lines, offering both technical and aesthetic advantages.

Warm Edge Spacer in India: Growing Demand and Local Supply

In India, the need for energy-efficient building materials has increased as energy regulations become stricter and awareness of sustainability grows. From high-rise residential towers to corporate buildings, thermal efficiency is now part of the design brief.

This has led to rising demand for warm edge spacer in India. Local manufacturers have started producing advanced spacer profiles to meet global standards while offering region-specific solutions. Suppliers now provide IGU manufacturers with consistent quality, reliable lead times and customisation based on client needs.

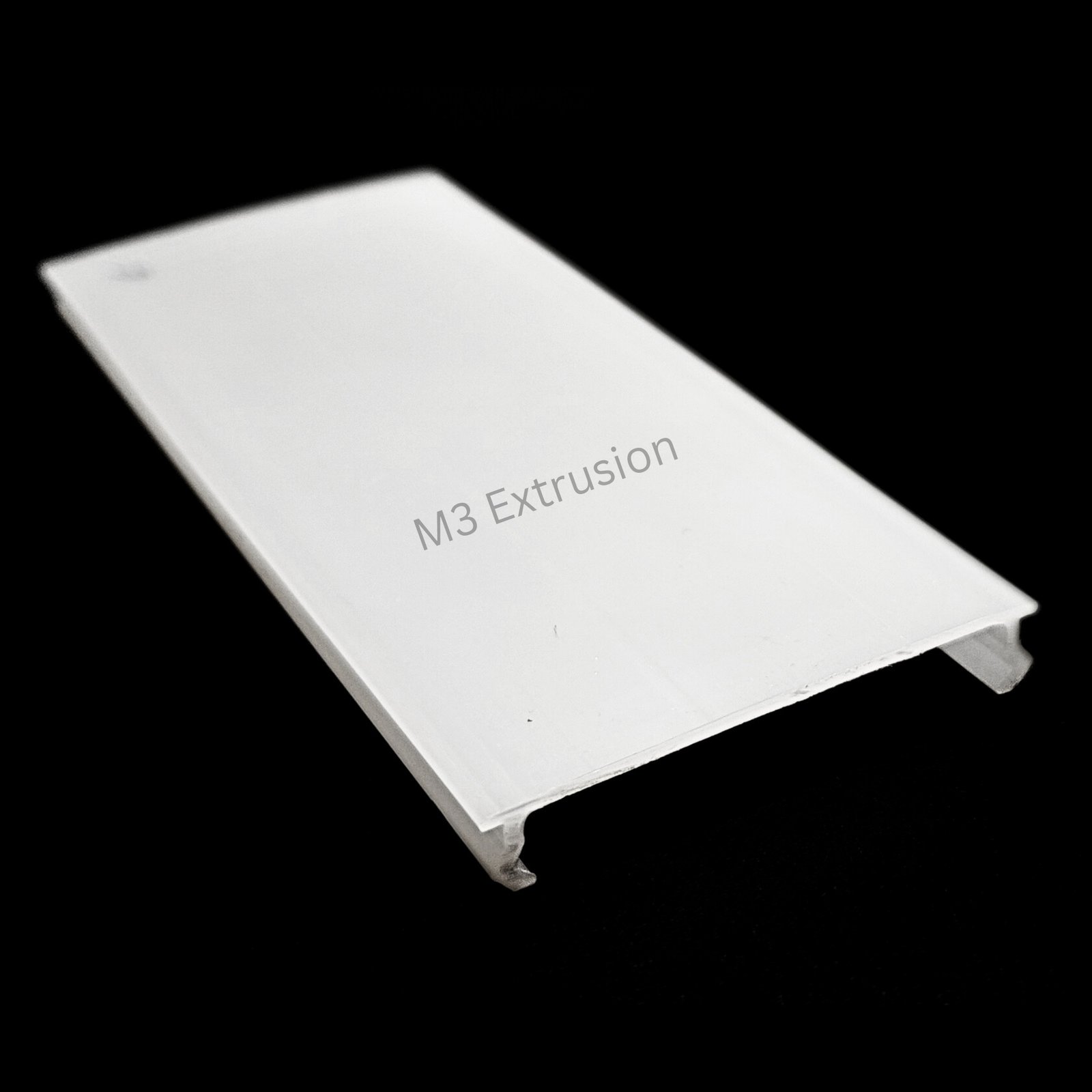

M3 Extrusion, one of the trusted names in this space, offers a range of plastic extrusion solutions including warm edge spacer profiles for double and triple glazing systems. Their precision manufacturing process and flexible service approach make them a dependable partner for glass processors, façade contractors and commercial window manufacturers across the country.

Why PVC Warm Edge Spacers Are a Smart Choice

Among the various materials used for spacer profiles, PVC warm edge spacers help lower energy bills and improve comfort without compromising strength or design. These spacers strike the right balance between thermal resistance, durability and ease of fabrication.

Key benefits of PVC warm edge spacers include:

- Excellent thermal insulation properties

- High resistance to UV rays, moisture and temperature fluctuations

- Minimal thermal expansion and contraction, reducing seal stress

- Smooth appearance and availability in multiple colours

- Compatibility with both manual and automated IGU assembly lines

As the window industry adopts smarter, energy-conscious systems, PVC spacers are gaining preference for their performance and practicality. They are widely used in both residential and commercial insulated glazing applications.

Real-World Applications of Warm Edge Spacers

Warm edge spacers are not limited to just homes. Their use is expanding across a range of sectors that require both insulation and transparency. Common applications include:

- Double and triple glazed residential windows designed for thermal comfort

- Commercial glass façades where energy efficiency supports building certification targets

- Glass partitions and skylights in modern office and institutional buildings

- Refrigerated display units in retail settings that require moisture control

- Structural glass units in public buildings such as airports, hospitals and shopping centres

In each of these areas, warm edge spacers provide improved window performance without adding complexity to manufacturing.

M3 Extrusion: Supporting Energy-Smart Glazing Systems

With industry demand increasing for high-performance IGUs, M3 Extrusion is focused on supplying dependable, precisely manufactured warm edge spacer profiles. Whether it’s a large façade contractor or a small IGU fabricator, M3 Extrusion offers spacer profiles that are compatible with a variety of glazing systems and production technologies.

As a plastic extrusion manufacturer based in India, M3 Extrusion helps bridge the gap between global glazing standards and local manufacturing needs. Their ability to provide warm edge spacer in India with consistent quality and design flexibility makes them a go-to source for commercial and architectural glazing projects.

FAQs

Why should I choose warm edge spacers instead of aluminium?

Warm edge spacers insulate better, reduce condensation and contribute to energy savings. Aluminium spacers allow more heat to escape and can shorten the life of the IGU due to thermal stress.

Are PVC warm edge spacers reliable over time?

Yes, PVC spacers are durable, weather-resistant and perform well in a wide range of conditions. They are suitable for both hot and cold climates and have excellent structural stability.

Can warm edge spacers be used in triple glazing systems?

Absolutely. Warm edge spacers are available in various widths and materials to suit both double and triple glazing applications.

Do warm edge spacers impact the appearance of the window?

They can actually improve it. Many warm edge spacers come in colour options and have a cleaner, softer appearance than aluminium, which blends better with modern window frames.

Is it possible to source warm edge spacer profiles locally in India?

Yes. Companies like M3 Extrusion manufacture high-quality warm edge spacer profiles in India, reducing import delays and offering customised options to match your IGU specifications.

Final Words

The shift from aluminium to warm edge spacers is more than just a material change. It represents a move towards smarter, more energy-conscious design in both homes and commercial buildings. From thermal insulation to long-term savings, the benefits of warm edge technology are clear.

With trusted suppliers like M3 Extrusion offering warm edge spacer in India, glass system manufacturers now have access to reliable, well-designed spacer solutions that help reduce energy costs and improve overall comfort. By adopting PVC warm edge spacers, businesses can deliver better performance while supporting sustainability goals in modern construction.