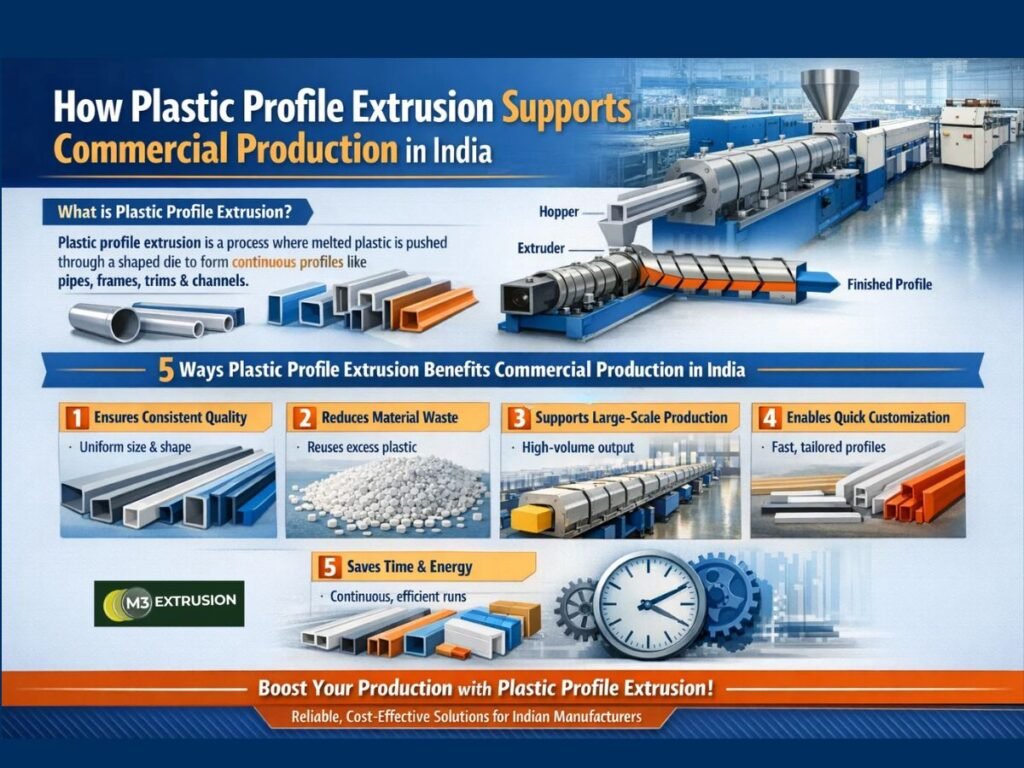

Over the years, plastic profile extrusion has become immensely popular, serving as a crucial part of commercial production in India. Plastic profile extrusion in India is a process where melted plastic is pushed through a shaped die to form long, continuous shapes like pipes, frames, trims, and channels. Once cooled, the plastic keeps the shape of the die, allowing precise and repeatable profiles.

Not only does this process allow factories to produce high volumes of consistent parts, but it also reduces material waste and keeps production costs in check. Indian manufacturers can run long batches without frequent stops, ensuring orders are completed on time. Its ability to maintain uniform size and shape makes it ideal for industries ranging from construction to automotive parts.

What is plastic profile extrusion?

Plastic profile extrusion is a process used to shape melted plastic into long, continuous forms. The melted plastic is pushed through a specially designed die, which gives it a fixed shape. Common profiles include pipes, window frames, trims, seals and channels. After the plastic cools, it retains the shape of the die, allowing consistent and repeatable profiles.

This process is widely used in commercial production because it can run for long periods without stopping, producing high volumes of uniform parts. It also helps reduce waste, since excess material can often be reused. Plastic profile extrusion works with many types of plastics, including PVC, HDPE and PP, making it flexible for different applications.

5 Ways Plastic Profile Extrusion Supports Commercial Production in India

Plastic profile extrusion plays a key role in supporting commercial production across India. It allows manufacturers to produce long runs of plastic profiles without frequent interruptions, which is essential for meeting large orders on time.

With profiles coming out the same every time, the process reduces errors as well as improves overall quality. It also helps lower production costs by limiting material waste, as excess plastic can often be reused. Plastic profile extrusion works with a variety of plastics such as PVC, etc., giving manufacturers flexibility to match the right material to the right application.

Additionally, the process makes it easy to produce custom shapes quickly, helping Indian manufacturers serve both local and export markets efficiently while keeping production smooth and reliable.

Here are five ways plastic profile extrusion supports commercial production in India.

Ensures Consistent Quality

Since production uses fixed dies, plastic profile extrusion creates parts that maintain uniform size, shape and dimensions, helping manufacturers deliver reliable products for commercial use.

- Reduces errors: Plastic profile extrusion keeps profiles consistent, preventing variations that could cause assembly or alignment issues.

- Supports assembly: This process ensures uniform profiles, making installation easier in construction, furniture, automotive and other sectors, so parts fit securely.

- Maintains product reliability: Plastic profile extrusion maintains the intended shape and performance of profiles during long production runs, even under frequent use or stress.

By producing consistent and precise profiles, plastic profile extrusion helps manufacturers maintain high-quality, dependable products in large-scale commercial production.

Reduces Material Waste

In addition to ensuring consistent quality, plastic profile extrusion also helps minimize waste, which keeps production costs lower and supports commercial production in India.

- Reuses excess material: Plastic profile extrusion allows leftover plastic to be recycled back into the process, reducing raw material consumption.

- Supports sustainable production: Efficient use of plastic through extrusion helps factories maintain high-volume output while meeting environmental goals.

- Improves cost efficiency: Plastic profile extrusion keeps material waste under control, which lowers per-unit production costs for manufacturers.

Plastic profile extrusion helps Indian manufacturers keep commercial production reliable by cutting waste and improving efficiency.

Supports Large-Scale Production

Plastic profile extrusion allows manufacturers to produce high volumes of uniform profiles without frequent stops.

- Meets production targets: Plastic profile extrusion enables manufacturers to maintain steady output for each batch, ensuring deadlines are met without compromising on profile quality.

- Improves quality control: Plastic profile extrusion allows manufacturers to monitor and adjust production in real time, ensuring every profile meets specifications and reducing the chance of defective parts.

- Saves time and energy: Continuous runs with plastic profile extrusion lower start-stop cycles, making large-scale production faster as well as more efficient.

By producing steady volumes with consistent quality, plastic profile extrusion supports reliable commercial manufacturing in India.

Enables Quick Customization

With plastic profile extrusion, manufacturers can produce custom shapes and profiles quickly to meet specific project requirements.

- Speeds up design changes: Plastic profile extrusion allows new dies to be implemented without slowing overall production.

- Supports diverse applications: Custom profiles created through plastic profile extrusion can be used in industries like construction, furniture, automotive and refrigeration.

- Meets local and export needs: Plastic profile extrusion helps factories deliver tailored solutions efficiently for both domestic and international clients.

Plastic profile extrusion helps Indian manufacturers stay flexible and meet high-volume commercial production while quickly adapting to design needs.

Saves Time and Energy

Plastic profile extrusion allows continuous production runs, reducing the need for frequent starts and stops and keeping commercial production efficient.

- Reduces downtime: Long runs using plastic profile extrusion help manufacturers keep production steady with fewer interruptions.

- Optimizes energy use: By minimizing start-stop cycles, plastic profile extrusion lowers energy consumption per unit produced.

- Supports faster delivery: Plastic profile extrusion allows factories to produce large orders efficiently, helping meet deadlines and the demands of commercial production in India.

Through steady, energy-efficient production, plastic profile extrusion helps manufacturers save time and keep large-scale commercial operations running smoothly.

Conclusion

Plastic profile extrusion supports commercial production in India by enabling manufacturers to produce large volumes of uniform, high-quality profiles efficiently. It reduces material waste, saves time and keeps production costs under control.

The process works with a variety of materials and can quickly adapt to custom designs, making it suitable for industries like construction, furniture, automotive, and refrigeration.

By combining efficiency, flexibility and reliability, plastic profile extrusion helps Indian manufacturers meet both local and export demand. For companies looking to scale production without compromising quality, adopting plastic profile extrusion is a practical, affordable and most of all dependable solution.

Are you searching for a reliable company that creates profiles using plastic profile extrusion? M3 Extrusion provides high-quality PVC profiles through plastic profile extrusion, with customization options to meet your production needs.

Frequently Asked Questions

What is plastic profile extrusion used for in commercial production?

Plastic profile extrusion is used to make long, uniform shapes like pipes, frames, trims and seals. It helps manufacturers produce large volumes of parts efficiently while keeping a consistent size, shape, and quality.

Can custom shapes be made through plastic profile extrusion?

Yes. Custom dies allow manufacturers to produce unique profiles quickly. This makes it easy to meet specific design needs for industries such as construction, furniture, automotive and refrigeration.

Which industries benefit most from plastic profile extrusion?

Industries like construction, furniture, automotive, lighting, refrigeration, and electrical fittings use extrusion. Any sector that needs long, uniform plastic profiles can benefit from this process.

Can extrusion profiles be modified after production?

Profiles can be cut, drilled, or assembled after extrusion. However, the main shape and dimensions are determined during extrusion, so proper planning ensures minimal adjustments afterward.

Check related articles for more insights:

- How Custom Extruded Plastic Supports Durable and Long-Lasting Products

- 7 Benefits of Custom Extruded Plastic for Complex Design Projects in the USA

- Reducing Waste and Cost Overruns with Custom Extruded Plastic in the USA

- 5 Cost Benefits of Using Custom Extruded Plastic in Bulk Orders