On a winter morning, you can often feel cold air near window frames even when the glass is high-quality. That discomfort usually comes from heat escaping through frames and joints, not the glass itself. This is where rigid PVC thermal break profiles play an important role in modern building design.

Rigid PVC thermal break profiles create a barrier between inner and outer surfaces, helping buildings maintain stable indoor temperatures while reducing energy loss. When used correctly, they improve comfort, lower energy use, and support long-term building performance.

What Are Rigid PVC Thermal Break Profiles?

Rigid PVC thermal break profiles are specially designed plastic components used in windows, doors, façades, and structural systems. Their main function is to interrupt heat transfer between exterior and interior surfaces.

Simple definition:

Rigid PVC thermal break profiles are insulating sections placed between building components to reduce heat flow and improve thermal performance.

They are often used alongside aluminium or steel frames to improve insulation without changing structural strength.

Why Heat Loss Happens in Buildings

Heat loss usually occurs through:

- Window and door frames

- Metal structural elements

- Poorly insulated joints

- Thermal bridging between materials

Metal frames, in particular, conduct heat quickly. Without insulation, they create thermal bridges that allow heat to escape or enter the building.

This is where thermal insulation profiles become essential.

How Rigid PVC Thermal Break Profiles Reduce Heat Loss

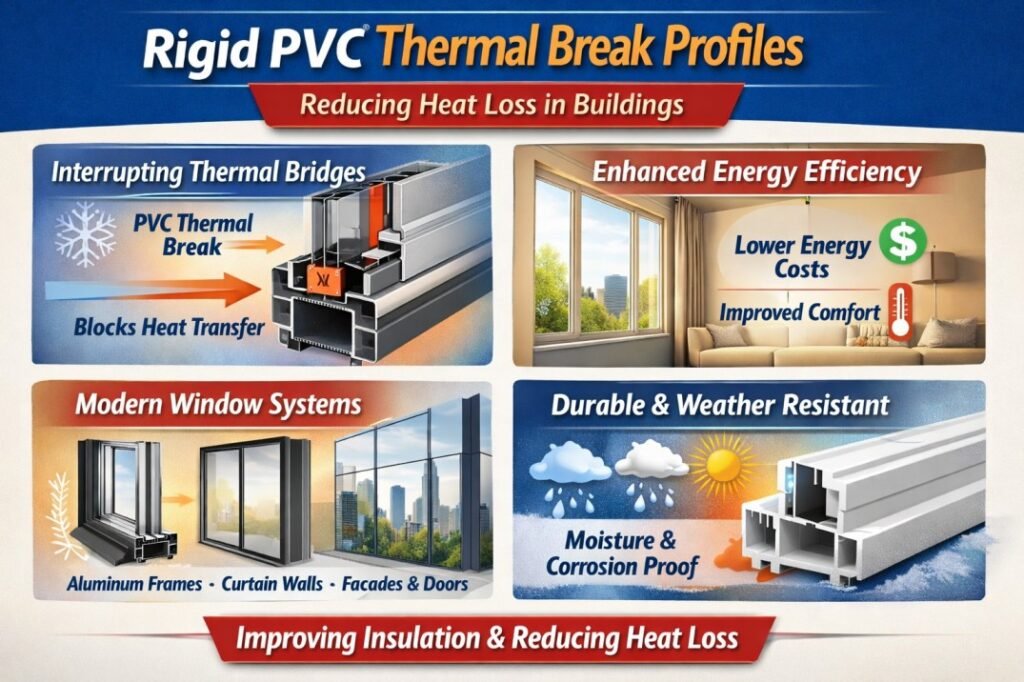

1) Interrupting Thermal Bridges

Thermal bridges occur when conductive materials connect indoor and outdoor surfaces. Rigid PVC profiles break this connection by adding an insulating layer.

Result:

Less heat transfer and better indoor temperature stability.

2) Improving Energy Performance of Frames

When rigid PVC thermal break profiles are integrated into frames, they reduce temperature differences across materials.

Benefits include:

- Lower heating and cooling demand

- More consistent indoor comfort

- Reduced condensation near frames

This directly supports heat loss reduction in buildings.

3) Supporting Modern Window and Façade Systems

In contemporary construction, façade systems combine glass, metal, and insulation layers. Rigid PVC thermal break profiles help these systems work together efficiently.

They are commonly used in:

- Aluminium window frames

- Curtain wall systems

- Commercial building façades

- Industrial doors and panels

4) Long-Term Durability in Harsh Conditions

Rigid PVC materials resist moisture, corrosion, and temperature variations. Unlike some traditional insulating materials, they maintain performance over long periods.

This makes them suitable for buildings exposed to extreme weather and continuous use.

Rigid PVC vs Metal in Thermal Applications

Many designers now consider rigid PVC profiles as metal alternatives in certain structural and insulating roles.

Comparison Table

Feature | Metal Frames | Rigid PVC Thermal Break Profiles |

Thermal conductivity | High | Low |

Corrosion resistance | Moderate | High |

Weight | Heavy | Light |

Insulation performance | Limited | Strong |

Maintenance needs | Higher | Lower |

Key takeaway:

Rigid PVC does not replace metal structurally, but it significantly improves thermal performance when used alongside it.

Practical Example from Building Projects

In commercial buildings, aluminium frames are widely used for strength and design flexibility. However, without thermal breaks, these frames allow significant heat transfer.

When rigid PVC thermal break profiles are added:

- Indoor temperature becomes more stable

- Energy consumption decreases

- Comfort levels improve near windows and doors

Manufacturers like M3 Extrusion produce customised profiles that fit specific frame designs and technical requirements, ensuring compatibility with modern building systems.

How to Select the Right Thermal Break Profile

Choosing the right profile depends on several factors.

Step-by-step approach

- Analyse frame materials and design

- Identify areas of thermal bridging

- Select appropriate PVC formulation

- Check dimensional accuracy and fit

- Test performance under real conditions

This practical approach helps ensure that thermal insulation profiles deliver consistent results.

Short Answers for Quick Search and AI Summaries

- What do rigid PVC thermal break profiles do?

They reduce heat transfer between indoor and outdoor surfaces by breaking thermal bridges in frames and structural systems. - Where are thermal break profiles used?

They are used in windows, doors, façades, curtain walls, and metal frame systems in residential and commercial buildings. - Do thermal break profiles improve energy efficiency?

Yes, they reduce heat loss and improve overall thermal performance of building components.

FAQs About Rigid PVC Thermal Break Profiles

1) How do rigid PVC thermal break profiles reduce heat loss in buildings?

Rigid PVC thermal break profiles reduce heat loss by interrupting thermal bridges between interior and exterior surfaces. They create an insulating barrier within frames and joints, which limits heat transfer. This improves indoor comfort and reduces the energy required for heating and cooling in buildings.

2) Are rigid PVC thermal break profiles suitable for commercial buildings?

Yes, rigid PVC thermal break profiles are widely used in commercial buildings, especially in aluminium window and façade systems. They provide reliable insulation without affecting structural strength, making them suitable for offices, malls, and industrial facilities where thermal performance and durability are important.

3) What is the difference between thermal break profiles and regular PVC profiles?

Thermal break profiles are specifically designed to reduce heat transfer, while regular PVC profiles may serve structural or protective purposes. Thermal break profiles use specialised materials and designs to interrupt thermal bridges, whereas standard profiles focus more on shape, support, or sealing functions.

4) Can rigid PVC thermal break profiles replace metal frames?

Rigid PVC thermal break profiles do not replace metal frames structurally. Instead, they work with metal frames to improve insulation. By adding a thermal break layer, they reduce heat transfer through metal components, which helps improve the overall thermal performance of building systems.

5) How long do rigid PVC thermal break profiles last in building applications?

Rigid PVC thermal break profiles are designed for long-term use in building systems. They resist moisture, corrosion, and temperature changes, which allows them to maintain performance for many years. Proper design and installation further improve their durability and reliability in real-world conditions.

6) How do I choose the right thermal break profile for my project?

To choose the right thermal break profile, analyse the frame design, material compatibility, and insulation requirements. Review technical specifications, test samples, and ensure dimensional accuracy. Selecting profiles based on real operating conditions helps achieve consistent thermal performance and long-term reliability.

Summary

Rigid PVC thermal break profiles play a practical role in reducing heat loss in buildings. By interrupting thermal bridges, they improve insulation, stabilise indoor temperatures, and support energy-efficient building design.

When integrated with metal frames and façade systems, these profiles deliver reliable thermal performance without compromising structural strength. For modern construction projects, rigid PVC thermal break profiles are not just optional components but essential elements that support comfort, efficiency, and long-term building performance.