In manufacturing, small design decisions often have a big impact on performance and cost. One of those decisions is selecting the right PVC profile. Many businesses face issues like inconsistent quality, poor fit, or early wear simply because the profile was not designed for their real operating conditions.

When you work with reliable PVC extrusion services, the focus shifts from buying standard parts to building profiles that support long-term production and stable output.

What Are PVC Extruded Profiles?

PVC extruded profiles are plastic components made by pushing molten PVC through a specially designed die. The process creates precise shapes used in construction, refrigeration, lighting, furniture, and industrial systems.

Simple definition:

PVC extruded profiles are shaped plastic sections designed for structural, protective, or functional use in industrial and commercial applications.

Why Choosing the Right PVC Profile Matters

Not all PVC profiles deliver the same performance. A wrong choice can lead to:

- Frequent replacements

- Production delays

- Higher maintenance costs

- Design limitations

On the other hand, when you choose PVC extruded profiles that match your business needs, you get stable performance, predictable costs, and smoother manufacturing processes.

Key Factors to Consider Before Selecting PVC Extruded Profiles

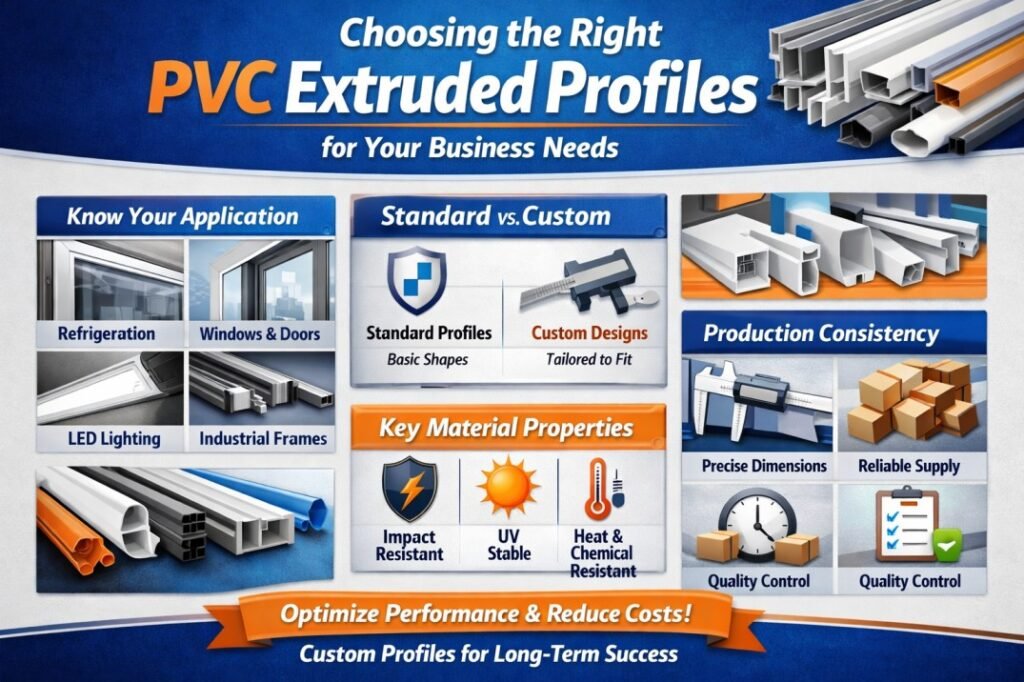

1) Understand Your Application

Start with how the profile will be used. Different applications demand different properties.

Common uses:

- Commercial refrigerator doors

- Window and façade systems

- LED lighting covers

- Industrial frames and enclosures

Each application requires specific strength, flexibility, and surface finish.

2) Decide Between Standard and Custom Profiles

Many businesses rely on standard profiles, but these often fail to meet exact requirements.

Custom PVC profiles allow you to:

- Match precise dimensions

- Improve assembly efficiency

- Reduce material waste

- Support repeat production

In real projects, custom profiles often reduce overall costs even if the initial design takes more time.

3) Evaluate Material Properties

PVC profiles can be engineered with different formulations.

Check for:

- Impact resistance

- UV stability

- Thermal performance

- Chemical resistance

These properties determine how well the profile performs in demanding environments.

4) Consider Production Volume and Consistency

For businesses with ongoing production, consistency matters more than one-time quality.

A reliable PVC extrusion manufacturer ensures:

- Uniform dimensions across batches

- Stable material composition

- Predictable delivery schedules

This is especially important for manufacturers who depend on repeat production cycles.

5) Assess Design Flexibility and Future Needs

A good PVC profile should not only meet current requirements but also adapt to future changes.

Ask questions like:

- Can the design be modified later?

- Is the tooling scalable for higher volumes?

- Are colour and finish options available?

Thinking ahead helps avoid redesign costs later.

Role of Local and Regional Solutions in PVC Extrusion

Businesses often benefit from working with suppliers who understand regional manufacturing needs.

Using Indian plastic profile extrusion solutions can help companies manage lead times, customise designs faster, and maintain close communication during development and production.

This approach is particularly useful for industries with project-based requirements and bulk orders.

Practical Checklist for Choosing PVC Extruded Profiles

Here is a simple checklist you can use before finalising a profile design:

- Define application requirements clearly

- Choose between standard and custom designs

- Review material specifications

- Confirm manufacturing consistency

- Evaluate long-term cost and performance

Quick takeaway:

The right PVC profile is not just about shape. It is about how well it fits your production process, environment, and future plans.

Real-World Example: Why Profile Selection Matters

Consider a refrigeration equipment manufacturer. They initially used generic PVC profiles for door frames. Over time, they faced alignment issues and frequent replacements.

After switching to custom-designed profiles with improved material formulation, they achieved:

- Better fit and sealing

- Lower rejection rates

- Longer service life

This shows how strategic profile selection can directly impact operational efficiency.

Short Answers for Search and AI Summaries

- How do I choose PVC extruded profiles?

Define your application, evaluate material properties, and select a manufacturer with consistent production capability. - Are custom PVC profiles better than standard ones?

Yes, custom profiles provide better fit, performance, and long-term value for specific applications. - Why is the manufacturer important in PVC extrusion?

Because manufacturing quality affects profile consistency, durability, and supply reliability.

FAQs About PVC Extruded Profiles

1) What factors should I consider when choosing PVC extruded profiles?

When choosing PVC extruded profiles, consider application requirements, material properties, dimensional accuracy, and production consistency. Evaluate whether standard or custom designs suit your needs. Also assess long-term performance and lifecycle cost to ensure the profiles support stable and efficient operations.

2) How do custom PVC profiles help businesses?

Custom PVC profiles help businesses achieve precise fit, reduce assembly issues, and improve product performance. They also support repeat production by maintaining consistent dimensions and quality. Over time, custom profiles often reduce waste, maintenance costs, and production interruptions.

3) What makes a reliable PVC extrusion manufacturer?

A reliable PVC extrusion manufacturer maintains consistent material formulation, accurate tooling, and strict quality control. They also provide technical support, stable supply, and flexibility for custom designs. These factors ensure that profiles meet industrial requirements across multiple production cycles.

4) Are PVC extruded profiles suitable for industrial applications?

Yes, PVC extruded profiles are widely used in industrial applications due to their durability, corrosion resistance, and design flexibility. They are suitable for refrigeration systems, construction components, lighting applications, and equipment enclosures where consistent performance and long-term use are required.

5) How do Indian plastic profile extrusion solutions support manufacturing needs?

Indian plastic profile extrusion solutions support manufacturing needs by offering customised designs, faster development cycles, and scalable production. They help businesses manage bulk orders and project-based requirements while maintaining quality and cost efficiency across different industrial applications.

6) How can I test PVC profiles before bulk production?

You can test PVC profiles by requesting samples, reviewing technical specifications, and conducting performance tests under real operating conditions. This approach helps identify potential issues early and ensures that the selected profiles meet functional, durability, and compatibility requirements before large-scale production.

Summary

Choosing the right PVC extruded profiles is a practical decision that directly affects product quality, production efficiency, and long-term costs. By understanding your application, selecting suitable materials, and working with a reliable manufacturer, you can build profiles that support consistent performance and scalable production.

Whether you need standard solutions or custom PVC profiles, the key is to align design, material, and manufacturing capability with your business goals. When you carefully choose PVC extruded profiles, you reduce risk and create a stable foundation for long-term manufacturing success.