Over the years, PVC rolling shutters have become immensely popular and are widely used in factories, warehouses and other industrial spaces to reduce noise, improve access, and protect work areas. As the name suggests, PVC rolling shutters are made from lightweight, durable plastic that rolls up and down along tracks to open or close large openings with ease.

Not only do these shutters help block outside noise, but they also make opening and closing large entrances smoother and easier for staff. The lighter material compared to metal requires less effort, even for bigger shutters.

These shutters can be operated manually or with a motor and they move quietly along their tracks without rattling or sticking.

PVC rolling shutters in the USA create a tight seal that keeps out dust, drafts and debris. This helps maintain cleaner and safer work areas. Unlike metal shutters, PVC does not rust or corrode. This makes it a reliable option even in humid or demanding industrial environments.

Maintenance of weather-resistant PVC rolling shutters is simple. Staff only need to clean them occasionally and lubricate the tracks to keep the shutters running smoothly.

With noise reduction, smooth operation, and low upkeep, PVC rolling shutters provide industries with a practical solution for safer, quieter, and more efficient workspaces.

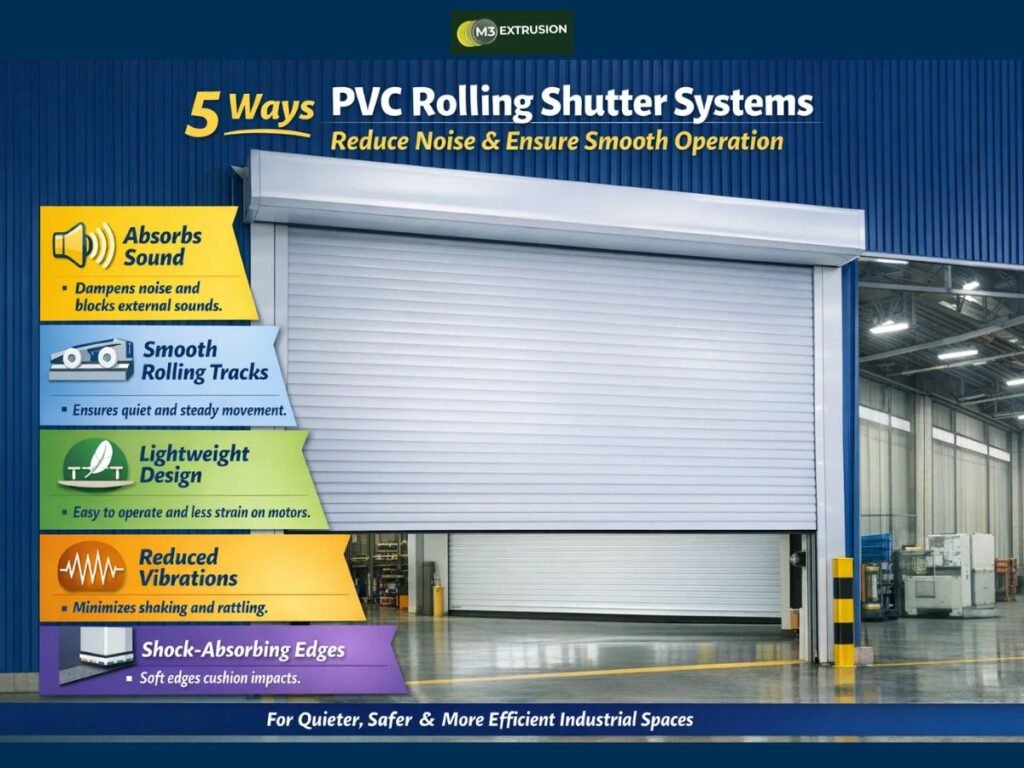

5 Ways PVC Rolling Shutter Systems Reduce Noise and Ensure Smooth Operation

PVC rolling shutters offer more than just a way to cover large openings. They are designed to improve the overall working environment by controlling noise and providing smooth movement. Their design and material make them effective in handling daily industrial challenges.

The lightweight PVC panels move easily along tracks, which reduces strain on motors as well as staff. The smooth motion prevents sudden jerks and vibrations, which can disturb workers or affect sensitive equipment nearby. Properly installed shutters also fit tightly, minimizing gaps where sound can enter or escape.

The shutters’ plastic construction absorbs some sound, unlike hard metal surfaces that reflect noise. This helps reduce echoes inside large industrial spaces. Besides, PVC is also resistant to wear and tear, meaning the shutters stay reliable for a long time, maintaining consistent performance over repeated use.

PVC rolling shutters are easy to operate and integrate with automation systems if needed. They allow quick opening and closing without causing unnecessary interruptions. Not to mention the fact that their low-maintenance design ensures that smooth movement and noise reduction are consistent over time, even in busy industrial environments.

By combining lightweight materials, tight-fitting and quiet operation, PVC rolling shutters help industries keep workspaces calm, safe and efficient, making them a practical choice for modern facilities.

Here are five ways PVC rolling shutter systems reduce noise and ensure smooth operation:

Absorbs Sound

Unlike metal shutters that reflect noise, PVC rolling shutters absorb sound, keeping industrial spaces quieter and making it easier for employees to focus as well as communicate.

- Minimizes echo: The PVC panels soften sound waves, reducing echoes and harsh reverberations in large work areas.

- Blocks external noise: The shutters act as a barrier, preventing loud sounds from outside from entering sensitive workspaces.

- Reduces operational noise: The lightweight panels and smooth tracks allow shutters to open and close quietly, lowering disturbances during repeated use.

By absorbing sound, PVC rolling shutters help maintain quieter operations, reduce distractions and improve overall working conditions in factories and warehouses.

Smooth Rolling Tracks

In addition to absorbing sound, PVC rolling shutters also slide easily along well-fitted tracks, which keeps the panels steady and allows smooth, quiet opening and closing in industrial spaces. The design of the tracks guides the shutters evenly, preventing jerks or misalignment during use.

- Prevents jerks and rattling: The tracks are carefully shaped and fitted, allowing PVC rolling shutters to slide evenly without sudden stops or vibrations.

- Supports heavy use: The shutters are balanced along the tracks, which helps them move smoothly even during frequent opening and closing.

- Reduces strain on components: Because the shutters slide easily along well-fitted tracks, there is less friction on the panels and motors, keeping movement consistent over time.

Smooth rolling tracks help PVC rolling shutters maintain steady, reliable movement, making operations easier and safer in industrial spaces.

Lightweight Design

Since PVC rolling shutters are made from lightweight material, they are easier to lift and slide along the tracks. This reduces the effort needed to open and close large shutters and keeps movement smooth and consistent.

- Supports automation: Because the shutters are light, motors can open and close them quietly and efficiently, without putting extra load on the system.

- Eases manual operation: The lightweight panels make opening and closing PVC rolling shutters effortless for staff, reducing physical strain during repeated use.

- Reduces wear on components: The lighter weight of PVC rolling shutters eases pressure on panels, tracks, and motors, which helps the system operate smoothly and last longer under frequent use.

The lightweight design lets PVC rolling shutters open and close easily, keeping daily industrial work smooth and safe.

Reduced Vibrations

PVC rolling shutters are designed to absorb and dampen movement, which prevents vibrations from traveling along the panels during operation. This keeps the shutters moving steadily and reduces unnecessary noise in industrial spaces.

- Minimizes panel shaking: The flexible PVC material absorbs small shocks, preventing the PVC rolling shutters from shaking or rattling while opening and closing.

- Protects the tracks: PVC rolling shutters move steadily with minimal vibrations, which keeps the tracks properly aligned and ensures reliable operation over time.

- Enhances durability: By limiting vibrations, PVC rolling shutters experience less stress on the panels and moving parts, extending the life of the system.

The reduced vibrations ensure PVC rolling shutters operate quietly, reliably, and consistently, improving both safety and comfort in factories and warehouses.

Shock-Absorbing Edges

In contrast to metal shutters that can rattle and create noise, PVC rolling shutters in the USA have shock-absorbing edges that cushion impacts when the panels reach the tracks or floor, reducing jolts and ensuring quiet operation.

- Reduces impact noise: Soft-edge sections in PVC rolling shutters absorb contact shocks, which lowers noise during opening and closing.

- Protects panels and tracks: With cushioned edges in place, PVC rolling shutters reduce direct impact on panels and tracks, helping them stay in better condition over time.

- Ensures smooth movement: By preventing sudden stops at the end of travel, PVC rolling shutters maintain steady motion during operation.

Shock-absorbing edges help PVC rolling shutters operate quietly and smoothly while supporting long-term use in industrial environments.

PVC rolling shutter systems are designed to support quieter and more controlled industrial operations. Not only do PVC rolling shutters help create calmer work areas, but they also reduce sudden impacts that can strain shutter components. This controlled movement helps maintain steady operation during frequent use.

Manufacturing units, warehouses, logistics centers and processing facilities benefit from this reliability, especially in areas where shutters are opened and closed many times a day. With easy handling and less disturbance, PVC rolling shutters provide a dependable solution for industrial areas.

Are you looking for high-quality PVC rolling shutter profiles for industrial use? M3 Extrusion offers a wide range of PVC rolling shutter profiles made from durable, high-quality materials using advanced extrusion technology.

Frequently Asked Questions

Do PVC shutters require regular maintenance?

PVC rolling shutters are easy to maintain. A little cleaning and track lubrication keeps them running smoothly, and the material resists rust and corrosion, so they need less care than metal shutters.

Can PVC rolling shutters handle large openings in warehouses?

Yes, PVC rolling shutters are lightweight and designed for large openings. These shutters glide easily along tracks, making it simple to use them by hand or motor, even for wide industrial spaces.

Are PVC rolling shutters suitable for humid or damp environments?

Yes, PVC shutters are resistant to rust and corrosion. They maintain smooth operation even in humid or damp conditions, making them reliable for factories, warehouses and other industrial spaces with challenging environmental factors.

How long do PVC rolling shutters typically last?

PVC shutters are durable and long-lasting. Their lightweight, corrosion-resistant material ensures they stay functional for years, maintaining smooth operation and noise reduction even under frequent industrial use.

Check related articles for more insights:

- A Complete Guide to Choosing the Best Rolling Shutter PVC for Your Facility

- Practical Benefits of Using PVC Rolling Shutters in Commercial Buildings

- How PVC Rolling Shutters Address Space and Installation Challenges in US Industries

- Tired of Heavy, Rusting Shutters? PVC Rolling Shutters Offer a Cleaner, Easier Solution for Commercial Projects in the USA